The hard "core" force behind zero-carbon heating

Extraction of steam from large nuclear power units for heating

Cogeneration has taken a new path for the comprehensive utilization of nuclear energy

Outside, the wind was blowing and the temperature dropped below freezing. However, in the home of Ms. Hou, a resident of Yasha Village in Haiyang City, it is warm as spring.

"There is no one living next door to my house, upstairs or downstairs, but the house is still very warm. The thermometer shows that the temperature in the room has reached 26 degrees Celsius. The temperature is more stable than before when we used to burn coal for heating." Ms. Hou said, holding a thermometer.

In Haiyang, there are many people who have the same feelings as Ms. Hou. And this is exactly the "warm nuclear No. 1" project put into operation to Haiyang City residents brought about immediate changes.

The reporter learned that "warm core No. 1" is a nuclear zero-carbon heating technology developed by the state power investment with completely independent intellectual property rights, and is also China's first comprehensive utilization of nuclear energy technology brand. This year is the second year that Haiyang City uses this technology to achieve nuclear heating.

Zhang Zhen, Shandong nuclear power design and management engineer. Although he is young, he has witnessed the whole process of innovative practice of comprehensive utilization of nuclear energy.

"Nuclear is more than electricity." Zhang Zhen told reporters that in most people's concept, when it comes to nuclear energy, the first thing that comes to mind is power generation, but in fact "nuclear energy has more possibilities", cogeneration is one of them, "that is, both power generation and heating."

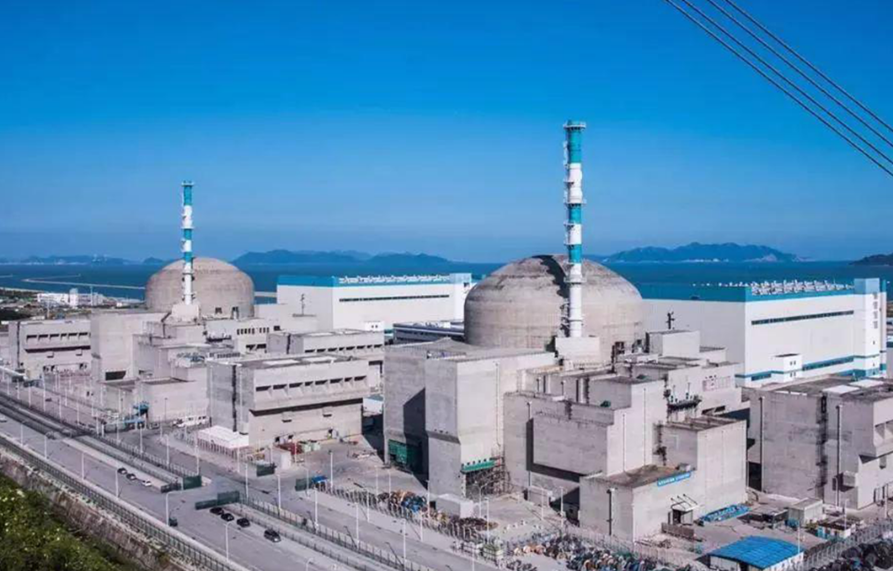

According to him, as the first nuclear power plant in Shandong Province to start construction and put into operation to generate electricity, Haiyang Nuclear Power plant plans to build 6 million kilowatt nuclear power units, reserving two room for expansion, with a total installed capacity of more than 10 million kilowatts. The two units of the first phase of the project are national third-generation nuclear power independent projects, which began to be connected to the grid in October 2018 and January 2019, respectively.

Prior to this, Wu Fang, chief engineer of nuclear energy development of State Power Investment Group Co., LTD., Party secretary and chairman of Shandong Nuclear Power Co., LTD., put forward the idea of nuclear energy heating, and led the team to take the lead in the research and practice of large-scale pressurized water reactor cogeneration. At that time, Shandong Nuclear Power developed a "three-step" strategy: the first phase of the park level auxiliary steam heating module (heating capacity 30 MW), the second phase of the county level extraction steam heating module (heating capacity 200 MW), the third phase of the regional level large-scale extraction steam heating module (heating capacity 900 MW) and other technical standardization programs. This set of nuclear heating technology is named "warm nuclear No. 1".

According to reports, the heating principle is from the Haiyang nuclear power unit to extract some of the steam that has been generated as a heat source, in the case of physical isolation, multiple heat exchange, and finally warm to the user's home. But these seemingly easy steps are not so easy to do.

"For the technical proposal alone, we designed nine different routes at that time. Whether it will be done, whether it will be accepted, those are the questions." Zhang Zhen told reporters.

In the winter of 2019, the 31.5 MW project of the first phase of "Warm Core No. 1" was put into operation, achieving heat supply to the surrounding 700,000 square meters, which is the first nuclear energy heating commercial project in China. At that time, the staff dormitory area and construction living area of the nuclear power plant took the lead in using nuclear energy heating, and the project was named "National Energy Nuclear energy heating commercial Demonstration Project" by the National Energy Administration.

But Zhang Zhen and his colleagues could not "breathe", and then they had to tackle the 202.5 megawatt project of the second phase of "warm nuclear No. 1", involving nearly 5 million square meters.

"Different from the first phase of the project, the second phase of the project to achieve a wider range of heating, the need to high-pressure cylinder exhaust pipe, valves, heat exchangers and a series of physical equipment to be reformed, but also involves a change in the control scheme." Zhang Zhen further explained that, for example, we have to pump more than 300 tons of steam from the high-pressure cylinder at one time, and the sudden change in pressure is bound to affect the operation of a series of equipment such as steam turbines.

Therefore, in the end how much to smoke, how to smoke, every link must not be careless. Finally, through multi-party cooperation, the project team has overcome a series of key technologies of "warm core No. 1" : filling the domestic gap in the extraction technology of the million-kilowatt medium pressure saturated turbine unit; New valves, such as large-diameter extraction check valve and quick-closing regulating valve, which are suitable for saturated steam, have been developed, which are the first in China in the key equipment of nuclear power cogeneration. The operation control strategy of matching reactor thermal power with turbine generator power + external heating power is developed, which makes a new leap in the operation control technology of nuclear cogeneration. Formed a complete set of safety and transient evaluation system based on nuclear power cogeneration, achieved zero breakthrough in the safety evaluation technology of domestic large nuclear power unit cogeneration...

In November 2021, the second phase of the "Warm Nuclear No. 1" project was put into operation, allowing Haiyang urban area to achieve a "seamless switch" from traditional coal-fired heating to nuclear clean heating, becoming the first city in China to achieve "zero carbon" heating. Haiyang Nuclear Power Unit 1 has become the world's largest cogeneration unit, and "warm core No. 1" has become one of the projects that earlier realized the requirements of the national "14th Five-Year Plan" on "carrying out demonstration of comprehensive utilization of nuclear energy such as Haiyang in Shandong Province".

According to reports, in July this year, the "warm core No. 1" 900 MW long-distance trans-regional nuclear energy heating project officially started, is expected to be put into operation in 2023. By then, the heating area can reach Yantai and Weihai areas, which can meet the heating needs of 1 million people.

Only heat transfer, no medium exchange

The multi-loop isolation design makes nuclear heating safer

In fact, at the beginning when I heard that the heating source of the community would change from burning coal to nuclear energy of the nuclear power plant, many local residents also had concerns. However, after looking deeper, they were reassured.

"Nuclear heating is not nuclear heating." Zhang Zhen told reporters that the heat extracted from the nuclear power unit is only a heat source, and it is necessary to pass a number of "boiling water" links in order to transfer the heat to the user through the municipal heating pipe network.

He and his colleagues often use the term "self-heating hotpot" to explain how nuclear heating works. "Self-heating hot pot" below is the heating layer, above is the food layer, after physical isolation, the following as the inedible part of the heating material, only play a heating role, and will not be in contact with the above ingredients.

"The key here is that there is only heat transfer, no medium exchange, nuclear heating is the same." Zhang Zhen introduced that the entire process of Haiyang nuclear heating is actually achieved through five physically isolated circuits.

The reporter learned that the primary circuit is completely closed in the reactor building. In the reactor, more than 150 fuel assemblies undergo nuclear fission reactions, releasing a large amount of heat, which will heat the high-pressure water in the primary circuit to more than 300 degrees Celsius.

Through the steam generator, the water in the second circuit absorbs the heat of the high pressure and high temperature water in the primary circuit, becomes saturated steam, and pushes the turbine to do work and generate electricity. Nuclear heating is to extract part of the overpowered steam from the second circuit of the nuclear power unit as a heat source, and heat the water in the third circuit through the first station of heat exchange in the plant.

"It's the equivalent of heating water with high-temperature steam in physical isolation." Zhang Zhen explained that the hot water of the three circuits heats the water of the four circuits in the heat exchange station of the heating enterprise outside the plant, completing the heat exchange of "water and water", and such an operation can continue to the five circuits or even more. The final output of water becomes the "heating water" that is transmitted to the residents' homes.

"In simple terms, nuclear heating is the transfer of heat through water. There are only two modes of heating water with steam or heating cold water with hot water." Zhang Zhen said that a number of circuits are set up between the nuclear power plant and the user for physical isolation, each loop only the transfer of heat, no water exchange, and at the user end, the hot water is only closed in the cell cycle, "very safe."

The data speaks for itself. The Shandong nuclear power plant provided the reporter with the radiation protection engineer's previous detection data on the radiation level of each circuit: The heat exchange station located in the nuclear power plant, where the steam is the first heat exchange, the measuring instrument showed the radiation dose of about 0.23 microsieverts per hour; In the office building of a nuclear power plant that uses nuclear heating, the measuring instrument shows 0.18 microsieverts per hour; The first nuclear heating station of the thermal company, the measuring instrument shows 0.18 microsieverts per hour; In a residential home with nuclear heating, the measuring instrument shows 0.20 microsieverts per hour...

"Radiation is everywhere in nature. Cosmic rays, soil, rocks, etc., all have a certain level of radioactivity, indoor tiles, marble, etc., will also produce radiation, through data testing, we can see that nuclear heating will not introduce additional radiation. According to statistics, the annual dose of natural radiation received by the average person in the world is 2,400 microsieverts, which is called the natural background level." According to professionals in the field of environmental monitoring, whether it is natural background radiation, or the radiation we are exposed to in our daily life, as long as it is controlled within a certain amount, it will not affect our health.

Warm a city, a blue sky

We will achieve win-win results in areas such as people's livelihood, environmental protection and economy

In an interview, Ms. Jia, a resident of Haiyang, told reporters that Shandong nuclear Power in promoting the popularization of nuclear energy heating made many residents, including her, very moved: warm a city, a blue sky. "For the first time, I feel that nuclear energy is really linked to the livelihood of our people." Ms. Jia said.

According to reports, after the second phase of the "warm core No. 1" was put into operation, the heating cost of Haiyang citizens was reduced from 22 yuan per square meter to 21 yuan, and they felt the real benefits.

It is not only the citizens who have actually benefited economically.

For the local heat company, before the implementation of nuclear energy heating, they have to buy 180,000 tons of raw coal from Hebei and other places every year, in addition to the investment in coal, transportation, desulfurization and environmental protection equipment and a large amount of electricity consumption. "In the past, the boiler is equipped with desulfurization equipment, and the daily power consumption is five or six thousand degrees, and now the daily power consumption is only about 600 degrees, plus the cost of saving equipment, labor, operation and maintenance, you can save a lot of costs." Fengyuan Heat Co., Ltd. relevant responsible comrades introduced that the former boiler workers said goodbye to the dirty working environment, and the rusty work clothes have been shelved. "The staff work less intensely, the working environment is better, but the income has not been affected at all."

For the Haiyang nuclear power Plant, energy efficiency and resource utilization have also been greatly improved. According to reports, after the first phase of the "warm core No.1" project was put into operation, the thermal efficiency of the whole plant was increased from 36.69% to 37.17%; After the second phase of the project was put into operation, the thermal efficiency increased to 39.94%; After the third phase of the project is put into operation, the thermal efficiency of the unit will be increased to 55.9%, 1.5 times that of the original. If the two units of Haiyang Nuclear Power plant carry out 900 megawatts of nuclear heating at the same time, it is equivalent to using less than 5% of the investment, adding a million kilowatt nuclear power unit.

When it comes to the economics of nuclear heating, Wu Fang believes that "in the long run, nuclear heating will be more affordable than burning fossil fuels."

In his view, based on the price of coal in the last two years plus the transmission cost of a certain distance, the price of using nuclear heating is slightly lower than that of coal heating. However, the price of fossil energy in the future may continue to rise due to production, reserves, and marketization of carbon emissions, and the use of nuclear energy is approximately a one-time investment, and the cost is mainly spent in the construction period. After production, the price of nuclear fuel accounts for less of the cost. Therefore, the cost of nuclear power generation and heating is relatively stable.

However, more eye-catching than the economic account is the environmental account.

Data from Shandong Nuclear Power show that up to now, the "warm core No. 1" project has completed three heating seasons, providing a total of 2.582 million gigajiao of clean heat, reducing raw coal consumption by 230,000 tons, and reducing carbon dioxide emissions by 420,000 tons. Among them, from November last year to April this year, the first heating season after the second phase of the "warm nuclear No. 1" project was put into operation continued to provide stable heating for 143 days, reducing raw coal consumption by about 180,000 tons, reducing carbon dioxide by 330,000 tons, nitrogen oxides by 2,021 tons, sulfur dioxide by 2,138 tons, and soot by 1,243 tons. Compared with the pre-nuclear heating, the PM2.5 in the air during the heating season decreased by 16%, and the good and good weather rate increased by 17%. The heat discharged into the environment has been reduced by 1.5 million GJ, and the regional Marine ecological environment has been significantly improved.

Safe, economical, clean, efficient... Haiyang nuclear heating has taken the first step of comprehensive utilization of nuclear energy in China. It is understood that as the largest nuclear heating project in China, the heating capacity of "warm core No. 1" accounts for more than 90% of the total national nuclear heating capacity.

In addition to Haiyang in Shandong province, the first nuclear heating project in northeast China, the Hongyanhe Nuclear heating demonstration project, also officially put into operation in November this year, covering Hongyanhe Town, Wafangdian City, Dalian City, Liaoning Province, benefiting nearly 20,000 local residents. Last year, Qinshan Nuclear Power Plant and Zhejiang Haiyan jointly built a nuclear heating demonstration project, creating a precedent for nuclear heating in southern China, and China's first nuclear industrial heating project was recently put into use.

"With zero-carbon heating, it warms thousands of households, protects the blue sea and blue sky, makes people's lives happier, makes the environment more comfortable and beautiful, and opens a door to innovation for the development of nuclear energy." Wu Fang said.

There is no end to innovation and development. According to reports, in addition to the "warm nuclear No. 1" phase III 900 MW nuclear heating project under construction, Shandong nuclear Power has also built the world's first "water and heat with the same generation" science and technology demonstration project, in the world for the first time to achieve "zero carbon" heating at the same time "zero energy" desalination of seawater, has become China's scientific research in the field of comprehensive utilization of nuclear energy innovation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands