Liquefied natural gas

Liquefied Natural Gas (LNG), the main component is methane, is recognized as the cleanest fossil energy on Earth. Colorless, tasteless, non-toxic and non-corrosive, its volume is about 1/625 of the volume of the same amount of gaseous natural gas, and the quality of liquefied natural gas is only about 45% of the same body of water.

The manufacturing process is to purify the natural gas produced in the field first, and after a series of ultra-low temperature liquefaction, the use of liquefied natural gas ships. Liquefied natural gas combustion after the air pollution is very small, and the release of heat is large, so liquefied natural gas is a relatively advanced energy.

Liquefied natural gas is natural gas compressed and cooled to its freezing point (-161.5 ° C) temperature after becoming a liquid, usually liquefied natural gas is stored in a low temperature storage tank of -161.5 ° C and about 0.1MPa. Its main component is methane, which is transported by special ships or tanker trucks and re-vaporized when used. Since the 1970s, world LNG production and trade have increased rapidly .

In 2021, China imported 81.4 million tons of LNG, overtaking Japan to become the world's largest importer of liquefied natural gas (LNG), marking the first time since the early 1970s that China has become the world's largest LNG importer, with Japan slipping into second place. The world's largest LNG supplier is Australia, with 83 million tons. Qatar followed with 81.3 million tons of LNG. The United States ranked third with 73.6 million tons of LNG.

In 2022, Qatar became the world's largest LNG exporter with 80 million tons of LNG exports

About:

Natural gas refers to flammable gas stored in the formation, mainly a mixture of low molecular alkane, can be divided into dry gas and wet natural gas two, dry gas composition is mainly methane, wet natural gas in addition to containing a lot of methane, but also contains more ethane, propane and butane.

The main components of Liquefied Natural Gas (Liquefied Natural Gas) are methane, with small amounts of ethane and propane. Liquefied natural gas is colorless, tasteless, non-toxic, non-corrosive, natural gas can be liquefied at atmospheric pressure and about -162 ° C, and the volume of liquefied natural gas is about 1/625 of the gaseous volume.

At atmospheric pressure, the density of LNG is about 430-470kg/m³ (slightly different depending on the composition), the ignition point is about 650℃, the caloric value is 52MMBtu (1MMBtu=2.52×108cal), and the explosion limit (volume) in the air is 5%-15%. The storage of liquefied natural gas is one of the natural gas storage methods. LNG storage tank is usually a double-layer metal tank, and the inner material in contact with LNG is 9%Ni low-temperature steel, the outer material is carbon steel, the middle insulation layer is expanded perlite, and the bottom insulation layer is foam glass.

In 2022, Qatar became the world's largest LNG exporter with 80 million tons of LNG exports, and global LNG exports reached 399 million tons, an increase of 5% .

Application editing broadcast

The world's advanced countries in environmental protection are promoting the use of LNG. In addition to being used as fuel for power plants, factories and household users, the methane contained in it can be used as chemical raw materials such as fertilizer, methanol solvent and synthetic acetic acid. In addition, the ethane and propane contained in it can be cracked to produce ethylene and propylene, which is an important raw material for plastic products.

In addition, ultra-low temperature LNG can provide a large amount of cold energy during the process of transforming into a normal temperature gas at atmospheric pressure, which can be recovered and used for six low temperature purposes: Make air separation to produce liquid oxygen, liquid nitrogen, liquefied carbon dioxide, dry ice manufacturing, the use of cold energy for power generation, the manufacture of frozen food or used in frozen warehouses, rubber, plastic, iron filings and other industrial waste low temperature crushing treatment, seawater desalination.

In the face of the increasingly serious ecological environmental pollution situation, in order to optimize the energy consumption structure, improve the atmospheric environment, and achieve sustainable economic development strategy, people choose natural gas as a clean, efficient ecological high-quality energy and fuel. Both industry and civil use are increasingly dependent on natural gas. Liquefied natural gas (LNG) is the liquid form of natural gas, and in some cases, choosing LNG has more advantages than choosing gaseous natural gas. The application of LNG is actually the application of natural gas, but due to its characteristics, LNG is more widely used than natural gas .

Industrial LNG

1. Power generation

The use of LNG is efficient and economical. In power generation, the thermal energy utilization rate of natural gas can reach 55%, which is higher than that of fuel oil and coal. Especially for peaking power plants, the advantage of natural gas replacing fuel oil is very obvious. Power generation is the most important industrial use of LNG.

Japan has been the world's largest importer of LNG, with more than 75 percent of its LNG imports used for power generation and 20 to 23 percent used as city gas. South Korea is also a big importer of LNG, with its power industry being the largest user of Korea Gas Corporation (Kogas), consuming more than half of the country's total LNG imports.

There are already many gas-steam combined cycle power plants fueled by natural gas or liquefied natural gas in the world. Between 1999 and 2020, about 90% of planned new electricity generation in the United States will be generated by natural gas, by which time the share of natural gas generation in the United States will reach 33% [3]. The combined cycle power stations that emerged in the 1980s mainly generated electricity from gas turbines (accounting for about 2/3 of the total electricity), and the pure efficiency of the power station has reached more than 50%, while the efficiency of conventional coal-fired steam turbine power stations is only 30% ~ 35% [3]. Gas turbine power plants and combined cycle power plants not only have high efficiency, but also good mobility, short running time from unit start-up to full load, which can be used for base load operation and peak load operation. In addition, combined cycle power plants have low pollution and high reliability.

China's "West-east natural gas Transmission" and other large-scale natural gas transmission and distribution projects have been completed. The first phase of the Guangdong LNG Station Line project was officially launched; The Fujian LNG project, with a total scale of 5 million t/ year and a total investment of more than 22 billion yuan in the first phase of the project, was also officially launched. The operation and start-up of these projects provide the necessary material guarantee for the natural gas power generation in developing China, and will certainly play an important role in alleviating the contradiction between energy supply and demand in China and optimizing the energy structure.

2, ceramics, glass and other industries

Some enterprises with large energy consumption are often far away from the city or the natural gas pipeline, or can not get the natural gas transported by the pipeline, in this case the advantages of LNG are more obvious, the most typical is the ceramic factory, the use of LNG can improve the product grade and reduce the cost. Used in glass, ceramic manufacturing and petrochemical and building materials industry (non-alkali glass cloth), can greatly improve the quality of products or reduce costs, so as to change fuel or raw materials, and become a new benefit growth point for related enterprises.

LNG for small and medium-sized towns

In recent years, with the improvement of residents' living standards, small and medium-sized urban residents prefer to use clean energy. LNG, as a clean energy, has attracted much attention. The carbon dioxide and nitrogen oxides produced by natural gas combustion are only 50% and 20% of coal, and the pollution is 1/4 of liquefied petroleum gas and 1/800 of coal. Due to the large investment cost of pipeline laying, LNG gasification station has a better economy than pipeline gas. In small and medium-sized cities and towns, LNG gasification station can be used as a gas source for residents, in addition, it can also be used for the life of commercial and public institutions and the heating of users.

LNG is used as a backup gas source for peak regulation

As the peak regulating gas source of pipeline natural gas, it can adjust the peak of civil fuel system and ensure the safe and stable gas supply of city. In the United States, the United Kingdom, Germany, the Netherlands and France and other countries, LNG peaking devices are widely used in natural gas transmission and distribution systems, which play a role in peaking the volatility of civil and industrial gas use, especially the sharp increase in winter gas use. China has built and put into use in Shanghai.

LNG fuel for vehicles

As a clean energy for sustainable development, LNG has obvious environmental and social benefits. Replacing fuel with LNG can reduce sulfur dioxide emissions by 90% and nitrogen oxide emissions by 80%, which has obvious environmental benefits and is a high-quality alternative fuel for automobiles. It can be predicted that cities will gradually replace fuel with LNG or natural gas in terms of vehicle fuel, and in recent years, it has been valued and promoted by many countries in the world. Russia has accumulated a lot of experience in using LNG for car transport, rail transport, water transport and air transport. Most transport companies in the UK use LNG as their vehicle fuel.

According to the different storage methods of natural gas, natural gas vehicles are roughly divided into CNGV (compressed natural gas vehicles), LNGV (liquefied natural gas vehicles), and ANGV (adsorbed natural gas vehicles). CNG vehicles are widely used in China, and LNGV vehicles are being promoted. ANGV is in the development stage. LNGV vehicles will gradually develop into heavy vehicles, and will partially replace small CNG vehicles and buses. At present, LNG bus demonstration stations have been built in Urumqi, Beijing and Changsha in Xinjiang Province, and Beihai and Zhanjiang cities are preparing for construction. Tens of thousands of CNG vehicles have been modified in the country, but the use of LNG as a vehicle fuel is particularly worth promoting, and the construction of LNG refueling stations while taking into account CNG (compressed natural gas) refueling stations can meet current and future needs.

Development overview edited broadcast

cause

In 1941, the world's first industrial-scale LNG plant was built in Cleveland, with a liquefaction capacity of 8,500m3 /d. Since the 1960s, the LNG industry has developed rapidly, the scale is getting larger and larger, and the basic load-type liquefaction capacity is 2.5×104m3/d. More than 160 LNG plants have been put into operation in various countries, and the total export of LNG has exceeded 46.18×106t/a.

The main component of natural gas is methane, and the atmospheric boiling point of methane is -161℃, the critical temperature is -84℃, and the critical pressure is 4.1MPa. LNG is short for liquefied natural gas, it is natural gas after purification (dehydration, dehydrocarbon, deacidic gas), the use of throttling, expansion and external cold source refrigeration process to make methane into a liquid and formed.

China's development

The development of China's natural gas trade not only reflects the change of the world natural gas market pattern, but also injects new vitality into the world natural gas market.

In 2011, China's natural gas production exceeded 100 billion cubic meters for the first time, reaching 101.18 billion cubic meters, a year-on-year increase of 6.4 percent. In the first eight months of 2012, the cumulative output reached 6.977 million tons, an increase of 5.4%. Natural gas pipeline construction is also in full swing. In 2011, China added more than 5,000 kilometers of long-distance natural gas pipelines, and the total length of dry and feeder natural gas pipelines exceeded 50,000 kilometers. On October 16, 2013, the three-tier West-East gas transmission project was started simultaneously in Beijing, Xinjiang and Fujian. Along the route, it passes through 10 provinces and regions, with a total length of 7,378 kilometers and a designed annual gas transmission capacity of 30 billion cubic meters .

Liquefied natural gas with the increasing import of liquefied natural gas at sea and the construction of liquefied natural gas liquefaction plants on land, domestic resource supply has been guaranteed. In 2011, China imported 12.215 million tons (17.1 billion cubic meters) of liquefied natural gas, about 1.3 times that of the previous year. China's offshore LNG imports will increase year by year in the future and are expected to reach 40 million tons in 2015, with a compound annual growth rate of more than 30% .

Today, China's three primary energy sources are oil, natural gas and coal. And natural gas can be second in the world. In recent years, due to the oil crisis in China, the domestic oil-producing areas have suffered serious losses. At the same time, the large-scale use of nature has caused serious pollution to the environment. This has led to the emergence of liquefied natural gas, a fuel-type fuel that is both environmentally friendly and clean. Today, in the international energy consumption market, natural gas energy consumption can account for 28% of the total consumption, but in China it only accounts for 2.8%, which is one of the reasons that lead to China's derailment from the world market.

China's current natural gas transport equipment is also relatively complicated, the installation of liquefied natural gas equipment is generally a vacuum insulated small tank, the inside volume is relatively small. And the delivery process is relatively slow and inefficient. Transport vehicles generally choose liquefied natural gas tank trucks, most of the models are semi-hung. However, with the improvement of science and technology, railway transportation will also be chosen in the transportation process, which will be widely used. In the face of the problem of natural gas installations in China, regional differentiation is also adopted, such as the installation in remote areas is generally smaller, while the installation in Shanghai Pudong is more inclined to liquefaction, and for the Central Plains, the load type is chosen. China is still a developing country, and is a large population of developing countries, the current economy is also in the process of slow development, which leads to China's demand for energy greatly increased, and China has been to oil as the main development of energy, but the current world oil development situation, oil prices are falling lower and lower, China has been unable to make ends meet in this respect. Demand for natural gas is growing in China's heavy industries, and much of the country uses the fuel-efficient fuel. With the growth of people's living standards, China's natural gas market also has a good opportunity to develop .

In 2021, China overtook Japan to become the world's largest importer of liquefied natural gas (LNG).

In May 2023, 51,000 tons of liquefied natural gas (LNG) supplied by petrochina International Corporation was successfully unloaded at the Hong Kong LNG receiving terminal.

On September 21, 2023, the world's largest floating storage regasification unit ship "Bauhinia Spirit" was put into operation in Hong Kong, marking the official operation of Hong Kong's offshore liquefied natural gas terminal.

Development of Russia

On November 22, 2013, the Russian State Duma passed a law to liberalize the export of liquefied natural gas from Russia, which will break the monopoly of LNG exports by Gazprom for many years.

The above laws came into force on December 1, 2013. According to the regulations, Russia will have two types of energy companies to obtain LNG export rights. Companies that hold a federal mineral resource extraction license issued before January 1, 2013, and are allowed to build liquefied natural gas plants, or use the extracted natural gas to produce natural gas. In addition, companies with more than 50% of the state capital have the right to exploit mineral resources in the inland sea, territorial sea and continental shelf, including the Black Sea and the Sea of Azov, and liquefied the gas extracted or obtained under product-sharing agreements.

According to the law, the Russian Ministry of Industry and Trade transferred the power to issue LNG licenses to the Ministry of Energy. Natural gas exporters will provide information to the Russian Energy Ministry on the export of natural gas in accordance with the procedures set by the Russian government, in order to coordinate the export of liquefied natural gas and avoid competition among Russian exporters.

The Russian government hopes that the liberalisation of LNG exports will help increase Russia's share of the world gas market and keep gas prices stable.

In the first 10 months of 2013, Russian natural gas exports amounted to 163.353 billion cubic meters, of which long-distance exports increased by 17.7% year-on-year to 109.871 billion cubic meters; Close-up exports fell 16 percent year-on-year to 41.663 billion cubic meters. In addition, LNG exports to the Asia-Pacific region in the first 10 months fell slightly by 1.6% year-on-year to 11.815 billion cubic meters.

Australian development

China National Offshore Oil Corp., one of the country's three state-owned oil companies, is issuing 10-year dollar-denominated bonds at an initial guide rate of about 210 dots for the same period U.S. Treasury notes. This is the first time that the Group has raised debt in the international market to fund its investment in the Curtis liquefied natural gas (LNG) project in Queensland, Australia.

The sale documents do not reveal the amount of debt sold, only the benchmark size. In the dollar bond market, the benchmark size generally refers to $500 million or more.

Cnooc Group is a central supergiant state-owned enterprise and China's largest offshore oil and gas producer, headquartered in Beijing. The main business includes oil and gas exploration and development, professional technical services, refining and chemical sales and fertilizer, natural gas and power generation, financial services, new energy and other six business segments.

The group is the parent of Hong Kong-listed CNOOC Ltd., which has sold debt in the international bond market several times, issuing US $4 billion in four tranches of US dollar bonds of different maturities in early May, but this is the first time CNOOC has sold debt overseas.

CNOOC Curtis Funding No. 1 Pty Ltd, a wholly owned subsidiary of CNOOC Group, was the issuer of the bond, with CNOOC Group providing a guarantee, according to the sales document. The bonds are rated preliminary "Aa3" by Moody's and preliminary "AA-" by Standard & Poor's and are scheduled to be listed on the Stock Exchange of Hong Kong.

CNOOC plans to use the proceeds from the bond sale for general corporate purposes for its CNOOC (AUS) Investment or subsidiaries, part of which will be used to acquire the Curtis LNG project, according to the filing.

Cnooc signed a $1.93 billion binding agreement with BP PLC in May to take a 40 percent stake in the Curtis LNG project, raising its total interest to 50 percent from 10 percent and including a 20-year supply contract.

Bank of China, Goldman Sachs, JP Morgan and UBS acted as joint global coordinators for the bond sale, according to the sales document. Together with ICBC International, CCB International, ABC Internaitonal and BOCOM International, Acting as joint bookkeeper and joint lead manager for the bond issue, which is expected to be priced as soon as today.

American development

On February 21, 2022, the latest annual liquefied natural gas (LNG) market outlook report released by international energy giant Shell believes that the United States is expected to become the world's largest LNG exporter in 2022. According to the Russian website on February 23, 2022, the United States liquefied natural gas exports continued to rise in 2021, an increase of 24 million tons over the previous year, of which nearly half were exported to Asia and about one-third were exported to Europe。

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

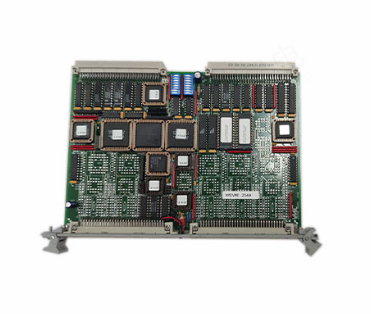

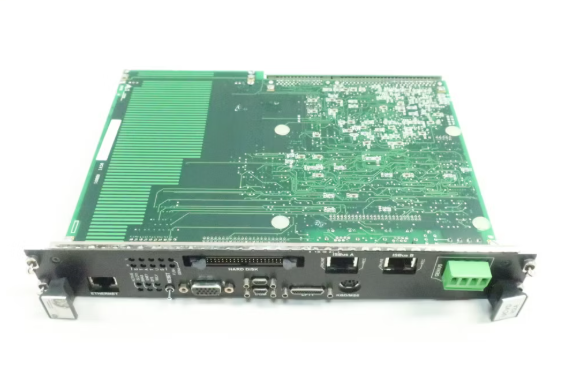

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com