Types, characteristics and applications of sewage treatment agents

First, the application field of water treatment agent

Its applications include industrial water, municipal/drinking water treatment, sewage wastewater treatment, and seawater desalination.

In the field of industrial water, it is mainly used in industrial circulating water treatment and industrial boiler water treatment. The chemicals used in industrial circulating water treatment mainly include scale inhibitor, corrosion inhibitor, bactericidal and algicidal agent, cleaning agent and pre-film agent. The common methods of industrial boiler water treatment are water treatment outside the pot and water treatment inside the pot, the main agents used are: corrosion and scale inhibitor, oxygen removal agent, feedwater alkali reduction agent, ion exchange agent, regenerant, softener, alkalicity regulator, scale cleaning agent, etc.

Municipal/drinking water treatment involves water treatment agents generally: bactericides and algaecides, flocculants, corrosion inhibitors, etc.

The water treatment agents involved in sewage treatment are generally flocculant, sludge dehydrating agent, defoamer, chelating agent, decolorizing agent and so on.

The main technologies of seawater desalination include distillation and membrane process. The membrane is easily blocked in use, so it is necessary to add scale inhibitor, detergent, flocculant, scale inhibitor and dispersant to the water. The distillation method is easy to produce scale and thus reduce the evaporation efficiency. Polyphosphate, organic phosphoric acid and phosphate-based polycarboxylic acid can be added to the raw water to soften the water quality, and calcium, magnesium ions and other metal ions can be chelated to make it not easy to precipitate and prevent the formation of scale.

Second, the type of water treatment agent

Water treatment agents include flocculants, corrosion inhibitors, scale inhibitors, biocides, dispersing agents, cleaning agents, pre-film agents, defoaming agents, decolorizing agents, chelating agents, deaerators and ion exchange resins.

1. About flocculants

It is a long talk about flocculants, and it is not easy to remember more, so summarize 3 points, the first point is that flocculants are mainly used to strengthen solid-liquid separation in the field of sewage treatment. The second point is that the flocculation effect can be enhanced by adding coagulant AIDS. The third point is that flocculants are the cheapest and most efficient method of phosphorus removal.

2. About coagulant aid

Summarize 2 points, the first point is that the role of coagulant is to regulate or improve coagulation conditions; The second point is that it can increase the grain size, density and fruity of alum flowers.

3. Corrosion and scale inhibitor

Corrosion and scale inhibitor, as the name suggests, is a water treatment agent that alleviates the scale and corrosion of circulating water equipment such as boilers. The agent is composed of alkaline substance and organic compound, adding corrosion inhibitor to prevent the heating surface from being corroded. The alkaline substance in the reagent, through chemical reaction in the boiler, reacts with the calcium and magnesium salt substances in the water to generate water slag, which is discharged from the boiler through the sewage function after precipitation, reduces the concentration of calcium and magnesium ions in the water, so that the boiler does not generate scale.

4. Cleaning agent

A cleaning agent is a volatile solvent that can dissolve the permeate and is used to remove excess permeate from the surface of the workpiece under test. Some cleaning agents are specifically designed to remove metal hydroxides, calcium carbonate and other similar scales attached to the surface of polyamides, polysulfones and film components. Check the cleaning tank, piping and security filter and install a new filter element before using the cleaning agent.

5. Fungicide

Fungicide is mainly a kind of medicine to destroy harmful bacteria such as bacteria and microorganisms. In the world, it is usually used as a general term for the prevention and treatment of various pathogenic microorganisms.

Common techniques:

1) Sterilization and disinfection: The disinfection method of water can be divided into two kinds: chemical and physical. Physical disinfection methods include heating method, ultraviolet method, ultrasonic method, etc. Chemical methods chlorine method, ozone method, heavy metal ion method and other oxidizing agent method.

2) Magnetization: The use of magnetic field effect for the treatment of water, known as the magnetization of water.

3) Precision filtration technology: microporous filter element and filter membrane made of special materials use their uniform aperture to trap particles, bacteria, etc., so that they can not be removed and trapped through the filter element and filter membrane. Precision filtration is capable of filtering micrometer (μm) or nanometer (nm) particles and bacteria. It is also widely used in the deep treatment of water.

4) Ultrafiltration technology: Ultrafiltration is a membrane separation technology. That is, under a certain pressure (the pressure is 0.07-0.7Mpa, the maximum is not more than 1.05Mpa), water flows on the surface of the membrane, water and dissolved salts in and other electrolytes are tiny particles, can penetrate the ultrafiltration membrane, and large molecular weight particles and colloidal substances are blocked by the ultrafiltration membrane, so that some of the particles in the water are separated technology. The pore size of the ultrafiltration membrane is determined by the retention test of a substance of a certain molecular weight, and the numerical value of the molecular weight is expressed.

5) Ozone: It is a gas that is blue at room temperature and has a special fishy smell. The molecular formula is O3. Ozone is highly oxidizing. Ozone is the protein oxidation and denaturation of bacteria, fungi and other bacteria, so that the electrolyte loses its effect, can kill bacterial propagules and spores, viruses, fungi, etc., and can destroy botulinum toxin, can remove and kill toxic substances and bacteria in air, water, food, can remove odor, widely used in food production disinfection, sterilization and other processes.

Ozone only produces non-toxic oxides during disinfection and sterilization, excess ozone is eventually reduced to oxygen, and there is no residue on the sterilized items, which can be directly used for disinfection and sterilization of food.

6) Ion exchange: The so-called ion exchange is the equal charge reaction between the ions in water and the ions on the ion exchange resin. Take the exchange reaction process of H+ type cation exchange resin HR and Na+ in water as an example: HR+Na+=Na++H+. From the above equation, it can be seen that in the ion exchange reaction, the cation in water (such as Na) is transferred to the resin, and an exchangeable H on the ion exchange resin is transferred to the water. The process of Na transfer from water to resin is the process of ion displacement. The process of exchange of H on the resin into the water is called the ionization process. Therefore, as a result of ionization and replacement processes, Na and H exchange positions, and this change is called ion exchange.

7) Ultraviolet: When lit, mercury lamp can emit ultraviolet light with a wavelength of 1400nm-4900nm (1nm=10-10m), which can penetrate the cell wall of bacteria, kill microorganisms, and achieve the purpose of disinfection and sterilization. Ultraviolet wavelengths are best at around 2600nm.

Ultraviolet disinfection is mainly used in drinking water with a small amount of treatment. Its characteristics are: strong killing ability, short contact time; The equipment is simple, the operation and management are convenient, and the treated water is colorless, tasteless and has no poisoning hazards; Does not increase the chlorine ions that occur when chlorine gas kills a virus.

8) Adsorption water purification technology: mainly refers to activated carbon and other material adsorption technology with adsorption capacity. Here only some of the characteristics of activated carbon, do a brief introduction: activated carbon is widely used in drinking water and food industry, chemical industry, power and other industrial water purification, dehydrogenation, oil removal and deodorization. Typically, 63-86% of colloidal material can be removed; About 50% iron; And 47% to 60% organic matter.

Three, common water treatment agent

1, polyaluminum chloride

Polyaluminum chloride is a kind of inorganic polymer coagulant. It is a kind of inorganic polymer water treatment agent with high molecular weight and high charge, which is produced by the bridging action of hydroxide ion and polymerization of polyvalent anion.

Features:

1) The flocculant has fast forming, good activity and good filterability.

2) Do not need to add alkaline additives, such as deliquescence, the effect is unchanged.

3) Wide PH value, strong adaptability and wide use.

4) Treated water contains less salt.

5) Can remove heavy metals and radioactive substances to the water pollution.

6) High active ingredient, easy to store and transport.

Functions:

1) Strong electric neutralization of colloidal substances in water.

2) Excellent bridging adsorption of hydrolysate to suspended matter in water.

3) Selective adsorption of dissolved substances.

Purpose:

1) Urban water supply and drainage purification: river water, reservoir water, groundwater.

2) Industrial water purification.

3) Urban sewage treatment.

4) Recovery of useful substances in industrial wastewater and waste residue, promoting the settlement of pulverized coal in coal washing wastewater, and recovery of starch in starch manufacturing industry.

5) Treatment of various industrial wastewater: printing and dyeing wastewater, leather wastewater, fluorinated wastewater, heavy metal wastewater, oily wastewater, papermaking wastewater, coal washing wastewater, mine wastewater, brewing wastewater, metallurgical wastewater, meat processing wastewater, sewage treatment.

6) Paper sizing

7) Liquid sugar refining

8) Casting molding

9) Anti-wrinkle fabric

10) Catalyst carrier

11) Pharmaceutical refining

12) Quick setting of cement

13) Cosmetic raw materials

2, polyferric sulfate

Polyferric sulfate is a light yellow amorphous powdery solid, easily soluble in water, 10% (by weight) of aqueous solution is a red brown transparent solution, hygroscopic. Polyferric sulfate is widely used in the purification of drinking water, industrial water, various industrial wastewater, municipal sewage, sludge dehydration and so on.

Compared with other inorganic flocculants, polyferric sulfate has the following characteristics:

1) New, high quality, high efficiency ferric salt inorganic polymer flocculant;

2) Excellent coagulability, dense alum, fast settling speed;

3) Excellent water purification effect, good water quality, no harmful substances such as aluminum, chlorine and heavy metal ions, no water phase transfer of iron ions, non-toxic, harmless, safe and reliable;

4) Removal of turbidity, decolorization, deoiling, dehydration, sterilization, deodorization, algae removal, removal of COD, BOD and heavy metal ions in water is significant;

5) The PH range of the water is wide 4-11, and the optimal PH range is 6-9. The PH value and total alkalinity of the raw water after purification are small, and the corrosion of the treatment equipment is small;

6) The purification effect of micro-pollution, algae, low temperature and low turbidity raw water is significant, and the purification effect of high turbidity raw water is especially good;

7) The dosage is small, the cost is low, and the treatment cost can be saved by 20%-50%.

3. Polyacrylamide

Polyacrylamide (PAM) is a water-soluble polymer, insoluble in most organic solvents, has good flocculation, can reduce the friction resistance between liquids, according to ionic characteristics can be divided into non-ionic, anionic, cationic and amphoteric four types.

Cationic polyacrylamide use precautions:

1) Flocs size: too small flocs will affect the speed of drainage, and too large flocs will restrain more water and reduce the degree of mud biscuit. The size of the floc can be adjusted by selecting the molecular weight of the polyacrylamide.

2) Sludge characteristics: The first point to understand the source, characteristics and composition of sludge, the proportion. According to the different properties, sludge can be divided into organic and inorganic sludge two kinds. Cationic polyacrylamide is used for the disposal of organic sludge, the relative anionic polyacrylamide flocculant is used for inorganic sludge, anionic polyacrylamide is used when the alkali is very strong, and anionic polyacrylamide is not appropriate when the acid is very strong, and the amount of polyacrylamide is usually large when the solid content of the sludge.

3) Floc strength: Floc should be stable and not broken under shearing. Improving the molecular weight of polyacrylamide or selecting suitable molecular structure is helpful to improve the stability of flocs.

4) the ionic degree of polyacrylamide: for dehydrated sludge, flocculants of different ionic degrees can be used to stop the selection of small tests, and the best suitable polyacrylamide can be selected, so that the best flocculant effect can be obtained, and the amount of medication can be added to the least and the cost can be saved.

5) Dissolution of polyacrylamide: good dissolution can give full play to the flocculation effect. Sometimes it is necessary to speed up the dissolution rate, at which time the concentration of the polyacrylamide solution can be considered.

Scope of application:

1) As retention agent and reinforcing agent in the papermaking process.

2) Water treatment as coagulant aid, flocculant, sludge dehydrating agent.

3) Used as water lowering agent and oil displacement agent in oil drilling and production.

4) PAM is also widely used in thickening, stabilizing colloid, reducing drag, bonding, film forming, biomedical materials and so on.

4, inorganic flocculant aluminum sulfate

The applicable pH range is related to the hardness of the raw water, the appropriate pH value is 5 ~ 6.6 for the treatment of soft water, 6.6 ~ 7.2 for the treatment of medium hard water, and 7.2 ~ 7.8 for the treatment of high hard water. The applicable water temperature range of aluminum sulfate is 20oC ~ 40oC, and the coagulation effect is very poor when it is lower than 10oC. Aluminum sulfate is less corrosive and easy to use, but the hydrolysis reaction is slow, and a certain amount of alkali needs to be consumed.

5, inorganic flocculant ferric chloride

Is another commonly used inorganic low molecular coagulant, the product has a solid dark brown crystal, but also has a higher concentration of liquid. It is easy to dissolve in water, large and heavy alum, good precipitation performance, wide range of adaptation to temperature, water quality and pH, etc. The applicable pH value range of ferric chloride is 9 ~ 11, the formed floc density is large, easy to precipitate, and the effect is still very good at low temperature or high turbidity. Solid ferric chloride has strong water absorption, strong corrosion, easy to corrode equipment, high corrosion requirements for dissolution and dosing equipment, pungent odor, poor operating conditions.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

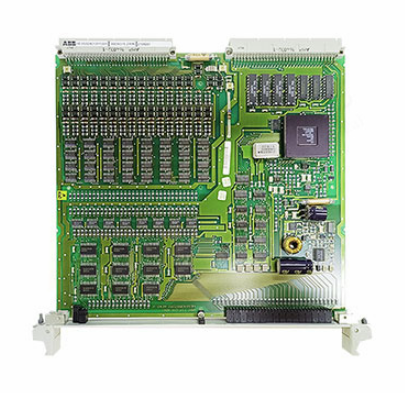

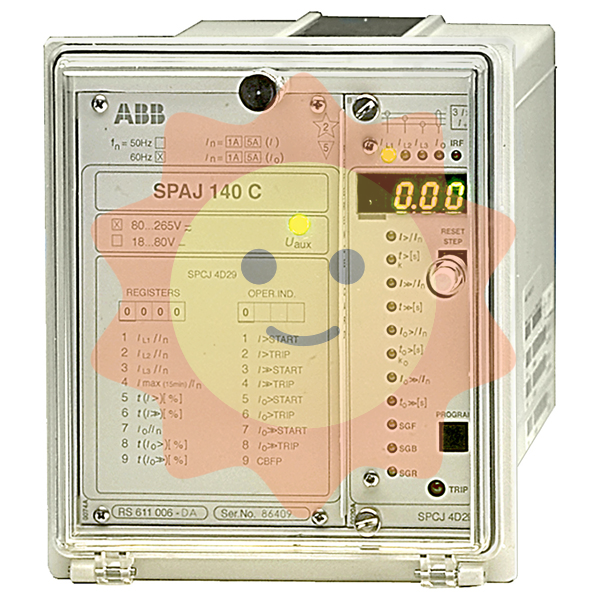

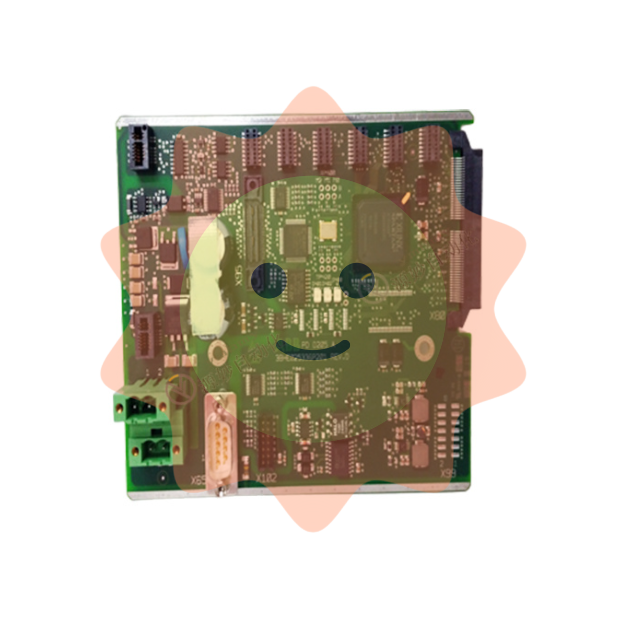

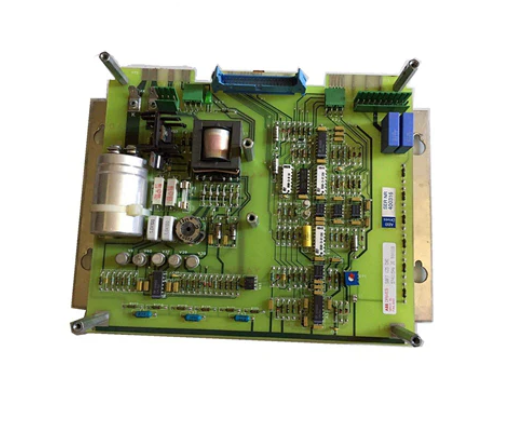

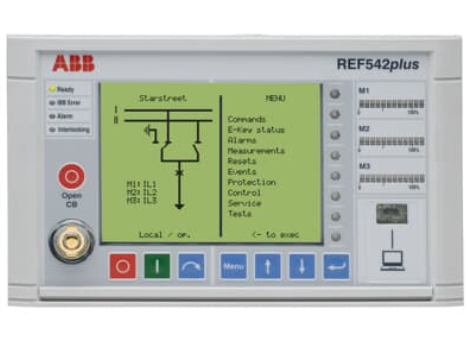

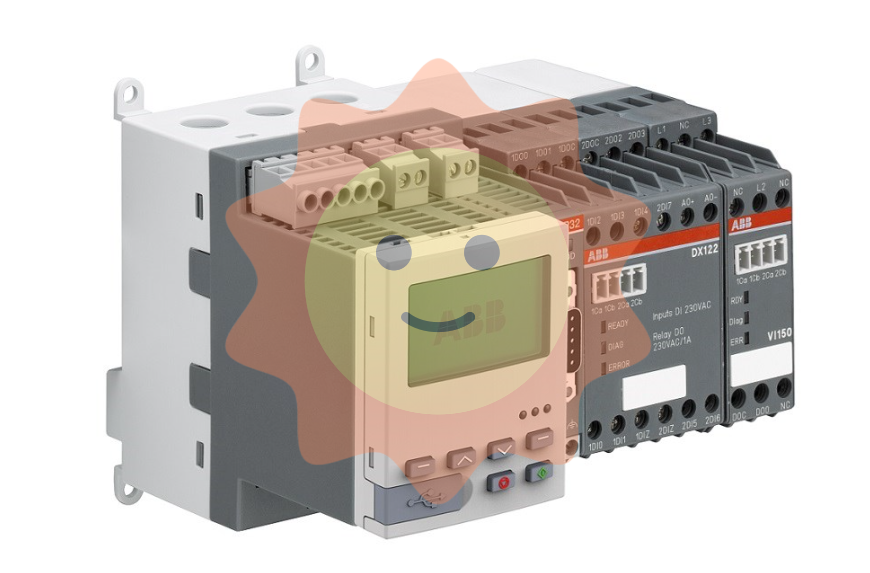

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

Email:wang@kongjiangauto.com