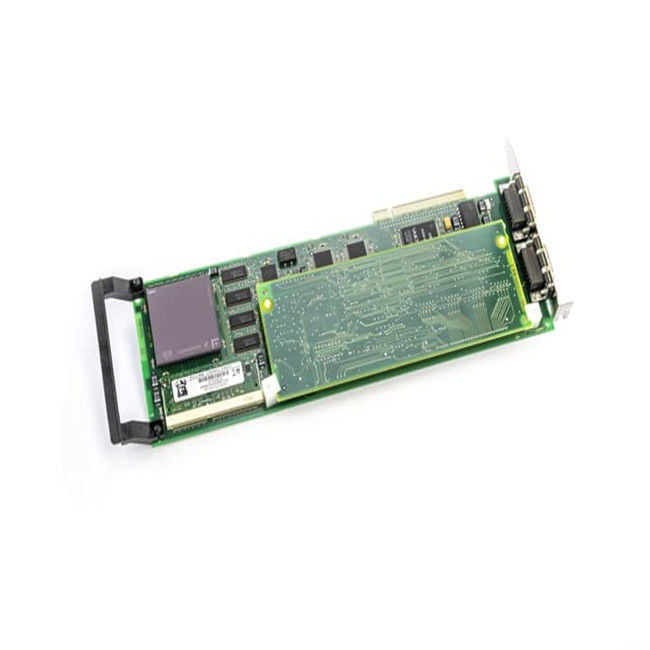

ABB 3BSE013064R1 PU516 Engineering Board -PCI

Process control system: in petrochemical, metallurgy, electric power and other industries, with the distributed control system (DCS), complete the temperature, pressure, flow and other parameters of real-time monitoring and control algorithms programming, to ensure that the production process is safe and efficient.

Intelligent building and energy management: Used in the program development of building automation system to achieve centralised control and energy optimisation of air-conditioning, lighting, lift and other equipment; in the energy management system, to improve the efficiency of energy use through data collection and analysis.

Mechanical equipment debugging: During the manufacturing process of machine tools, printing machines and other equipment, engineers use the PU516 to debug equipment functions and optimise parameters to ensure that mechanical equipment meets design requirements and performance indicators.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands