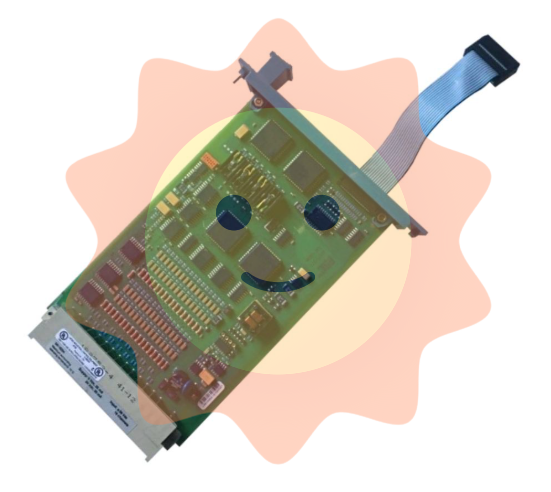

ABB 3HAC5566-1 Industrial Control Module

ABB 3HAC5566-1 Industrial Control Module

Product Overview

ABB 3HAC5566-1 Industrial Control Module is a high-performance industrial control module designed to meet the needs of complex industrial automation scenarios. In the industrial production process, precise control and stable operation of equipment are crucial. As the core component of the automation control system, this module undertakes key tasks such as data processing, instruction sending, and equipment coordination, which can effectively improve the efficiency, accuracy, and reliability of industrial production.

Core functions

Precise control: By accurately collecting and processing input signals, combined with advanced control algorithms built in, precise control of industrial equipment is achieved. Whether it is adjusting the motor speed, controlling the valve opening, or accurately adjusting parameters such as temperature and pressure, 3HAC5566-1 can ensure that the control accuracy meets the requirements of industrial production.

Data processing and storage: Its powerful data processing capabilities enable it to process large amounts of data from sensors, actuators, and other devices in real-time, and analyze, filter, and store the data. These data can be used for production process monitoring, fault diagnosis, and process optimization, helping enterprises achieve intelligent production management.

Communication and Networking: Rich communication interfaces and protocol support enable this module to easily connect to industrial automation networks. It can communicate with control systems such as PLC and DCS to achieve collaborative work between devices; At the same time, data can also be uploaded to the upper computer monitoring system, making it convenient for operators to remotely monitor and manage the production process.

Fault diagnosis and protection: Built in self diagnostic function, which can monitor the real-time operation status of the module itself and the working condition of connected devices. Once a fault is detected, such as communication interruption, abnormal input and output, overheating, etc., the module will immediately trigger an alarm mechanism and take corresponding protective measures, such as cutting off output, stopping equipment operation, etc., to prevent the fault from expanding and ensure production safety.

Working principle

When the 3HAC5566-1 Industrial Control Module is working, it first receives signals from various sensors (such as temperature sensors, pressure sensors, position sensors, etc.) through input channels. These signals are preprocessed through filtering, amplification, etc., and then converted into digital signals that are transmitted to the internal processor of the module. The processor analyzes and calculates input data based on preset control programs and algorithms, and generates corresponding control instructions. Then, control instructions are sent to actuators (such as motors, solenoid valves, regulating valves, etc.) through output channels to drive the equipment to perform corresponding actions. Throughout the process, the communication interface is responsible for exchanging data with external devices and systems, ensuring that the module can timely obtain external information and upload operational data. At the same time, the fault diagnosis module continuously monitors the system status and immediately alarms and handles any abnormalities found.

Key advantages

High performance and high reliability: Using high-quality electronic components and advanced manufacturing processes, the module undergoes rigorous testing and verification to ensure long-term stable operation in harsh industrial environments. The strong anti-interference ability and perfect fault protection mechanism effectively ensure the reliability and stability of industrial control systems.

Flexibility and Scalability: Rich input/output channels and support for multiple communication protocols enable it to flexibly adapt to different industrial control scenarios. In addition, the module also supports modular expansion, allowing users to add or replace functional modules according to their actual needs, facilitating system upgrades and modifications.

Easy to use and maintain: Provides an intuitive and user-friendly interface and detailed operation manual, reducing users' learning costs and difficulty in use. The structural design of the module is easy to install and disassemble, and supports online diagnosis and remote maintenance functions, which can significantly shorten the time for troubleshooting and repair, and reduce maintenance costs.

Good compatibility: It can seamlessly integrate with industrial equipment and control systems from ABB and other brands, facilitating users to build unified industrial automation solutions and improving the overall performance and collaborative efficiency of the system.

Precautions

Installation requirements: During installation, ensure that the module is securely installed to avoid loose connections caused by vibration. At the same time, it is necessary to ensure that the installation environment is dry, well ventilated, and away from strong electromagnetic interference sources. The environmental temperature and humidity of the installation location should be within the working range specified by the module.

Wiring specifications: Strictly follow the product manual for wiring operations to ensure correct and error free power and signal wiring. Different types of signal lines should be wired separately to avoid signal interference. After the wiring is completed, it is necessary to carefully check whether the wiring is secure to prevent poor contact from affecting the normal operation of the module.

Parameter configuration: Before use, it is necessary to correctly configure module parameters according to the actual application scenario, including communication protocol, baud rate, device address, input/output type, etc. Incorrect parameter configuration may result in module communication failure or control errors. Testing and verification should be conducted after the configuration is completed.

Maintenance: Regularly inspect and maintain the module, clean the surface dust of the module, and check whether the connecting cables are damaged. If the module malfunctions, the fault alarm information should be checked first, and the troubleshooting guide should be followed for handling. Non professionals are not allowed to disassemble the module without authorization.

Similar model supplement

ABB 3HAC5566-2 Industrial Control Module: Compared with 3HAC5566-1, 3HAC5566-2 has adjustments in the number and types of input/output channels, making it suitable for industrial control scenarios with different channel requirements. For example, it may increase the number of analog input channels, making it more suitable for applications that require the collection of large amounts of analog signals, such as temperature, pressure, and flow monitoring in chemical production processes.

ABB 3HAC5566-3 Industrial Control Module: This model has been upgraded in communication functionality, supporting more industrial communication protocols or having higher data transmission rates. It is suitable for large-scale industrial automation systems with high communication requirements, such as integrated control systems in smart factories, and can achieve faster and more stable data exchange between devices.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands