The main quality index of chemical fiber

The quality of chemical fiber refers to the index that has decisive significance for the use value of fiber products. Physical performance indicators, including fiber length, fineness, density, gloss, moisture absorption, thermal properties, electrical properties, etc.; Mechanical property index, including breaking strength, elongation at break, initial modulus, resilience resistance to multiple deformation, etc.

Stability performance indicators, including high and low temperature stability to light and atmosphere, stability to light and atmosphere, stability to chemical agents and microbial action stability; Processing performance indexes, including fiber adhesion, electrical and dyeing properties, etc. Additional quality indicators of staple fibers, including fiber length, crimp, fiber defects, etc

First, fineness

Fineness is the degree of fiber thickness, divided into direct indicators and indirect indicators. Direct indicators are generally expressed by the diameter and cross-sectional area of the fiber, because the cross-sectional area of the fiber is irregular and not easy to measure, usually there are not many direct indicators to indicate its thickness, so indirect indicators are often used. Indirect indicators are determined by fiber quality or length, that is, the quality (fixed length system) or length (fixed weight system) of the fiber, which is usually expressed by the fiber quality per unit length in the chemical fiber industry, that is, linear density (densification), which is commonly used in the following three ways.

1. tex or Fen (dtex)

Tert or minute is the international system of units. The mass (g) of the 1000m long fiber is called special; One tenth of that is a minute. Because the fiber fineness is finer, the value is smaller when the fineness is expressed by the special number, so the fineness of the fiber is usually expressed by the minute.

For the same kind of fiber (that is, when the density of the fiber is certain), the smaller the number, the finer the single fiber, the softer the feel, the softer the luster and the easy to deform processing.

2. denier

The mass (g) of 9000m long fiber is called denier, and for the same fiber, the smaller the denier, the finer the single fiber. Denier is a non-legal unit of measurement of linear density. 1den=9tex.

3. Metric Count (Nm)

The metric count, referred to as the common count, refers to the length (m) of the fiber per unit mass (g). For the same fiber, the higher the count, the finer the fiber. The metric count is a non-legal unit of measurement of linear density.

The values of tert or fen, denier and count can be converted to each other, and the relationship is as follows.

Denier * count =9000

Special number * count =1000

Denier =9* characteristic number

Splitter =10 x splitter

2. Density

Density of a fiber (densities) refers to the mass of the fiber per unit volume in g/cm³. The density of various fibers is different, in the main chemical fiber varieties, the density of polypropylene is the smallest, the density of viscose fiber is the largest.

Third, hygroscopicity

The hygroscopic property of the fiber refers to the water absorption of the fiber under the condition of standard temperature (20℃, 65% relative humidity), which is generally expressed by two indicators.

Moisture regain: the ratio of the moisture weight in the fiber to the dry weight of the fiber. That is, moisture regain = weight of moisture contained in the sample/weight of the dry sample *100%

Moisture content: The ratio of the weight of water in the fiber to the wet weight of the fiber. That is, moisture content = weight of moisture contained in the sample/weight of the undried sample *100%

The hygroscopicity of various fibers varies greatly, and the hygroscopicity of the same fiber also varies greatly due to the difference in ambient temperature and humidity. In order to calculate the weight and check the needs of the price, it is necessary to make a unified provision for the moisture return rate of various textile materials, called the public moisture return rate.

Hygroscopicity affects the processability and serviceability of fiber. The friction and electrostatic effect of good hygroscopic fibers are reduced, and the wearing comfort can be improved by modifying synthetic fibers with poor hygroscopic properties.

4. Tensile properties

Fiber materials in use will be stretched, bending, compression, friction and torsion, resulting in different deformation. The main external force of chemical fiber in the use process is tension, and the bending property of the fiber is also related to its tensile property, so the tensile property is the most important mechanical property of the fiber. The tensile properties of fiber are mainly measured by the following three indexes: breaking strength, elongation at break and initial modulus.

1. Breaking strength

Relative strength is commonly used to indicate the breaking strength of chemical fibers. That is, the ratio between the maximum load that the fiber can withstand until it breaks and the linear density of the fiber under the action of continuous increasing load. The unit is N/tex, centin /te

(cN/tex).

The breaking strength is an important index to reflect the quality of fiber, high breaking strength, fiber in the process of processing is not easy to break, roll, yarn and fabric fastness is high, but the breaking strength is too large, fiber rigidity increases, feel hard.

The strength of the fiber measured in the dry state is called dry strength; The strength measured in the wet state is called the wet strength. The wet strength of the fiber with higher moisture regain is lower than that of the dry strength. Most synthetic fibers have very low moisture regain, and wet strength is close to or equal to dry strength.

2. Elongation at break

The elongation at break of a fiber is generally expressed as the relative elongation at break, that is, the ratio of the length of the fiber extended to break to the original length.

Y= (L-L0) L0*100%

Where: Lo - fibrous length

L - The strength of the fiber at elongation to break.

Elongation at break is an index of fiber toughness. For the clothing filament, the greater the elongation, the softer the feel, the less hair and broken end in the post-processing, but when it is too large, the fabric is easy to deformation. For industrial filaments, the smaller the elongation, the less susceptible the final product is to deformation.

3. Initial modulus

The initial modulus of the fiber is the elastic modulus, which refers to the stress required when the fiber is stretched to 1% of its original length.

The initial mode indicates the resistance of the fiber to small deformation. In clothing, it reflects the stiffness of the fiber against small stretching or bending. The larger the initial modulus of the fiber, the easier it is to deform. Among the main varieties of synthetic fibers, the initial modulus of polyester is the largest, followed by acrylic fiber, and nylon is smaller. Therefore, polyester fabric is crisp, not easy to wrinkle nylon is easy to wrinkle, poor shape preservation.

Five, resilience

The deformation of the material under the action of external forces (stretching or compression), after the removal of external forces, the ability to return to the original state is called elastic recovery. The deformation of fiber under load includes three parts: common elastic deformation, high elastic deformation and plastic deformation. These three kinds of deformation do not appear one by one in turn, but develop simultaneously, only at different speeds.

Therefore, when the external force is removed, the recoverable general elastic deformation and the part of the high elastic deformation (rapid rebound deformation) with short relaxation time will quickly shrink, and leave a part of the deformation, that is, the residual deformation, including the high elastic deformation with long relaxation time (slow rebound deformation) and the irreversible plastic deformation. The smaller the residual deformation value, the better the resilience of the fiber.

Six, dry uneven rate

Dry irregularity is an indicator of the evenness of the filament, expressed as CV value (coefficient of variation) or mouth (Uster%). This index is particularly important for top oriented and drawn filaments. Filament dry uneven, in the process of processing is easy to produce hair and dyeing uneven.

Seven, crimp degree (mainly for short fibers)

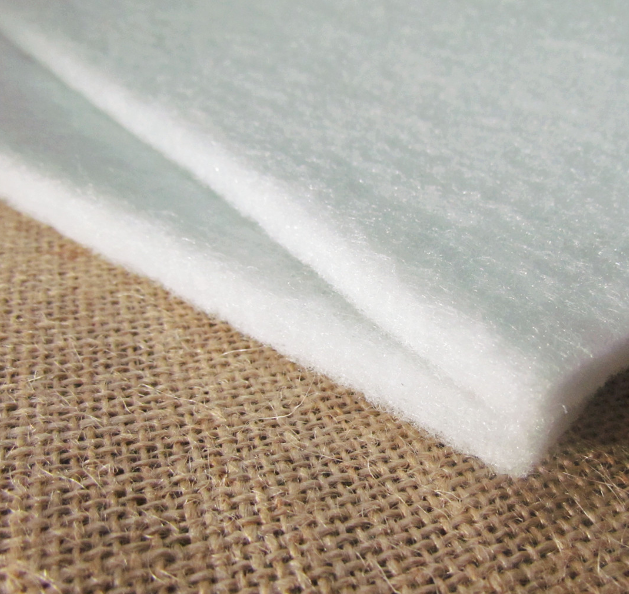

The fiber is chemically, physically or mechanically crimped and deformed to give the fiber a certain crimp.

The purpose of crimping is to improve the adhesion of the fiber, while increasing the fluffiness and elasticity of the fiber, so that the fabric has a good appearance and warmth.

Eight, boiling water shrinkage rate

After the fiber is boiled in boiling water for 30 minutes, the ratio of the length after contraction to the original length is called the shrinkage rate of boiling water.

Boiling water shrinkage is an index of fiber thermal setting degree and dimensional stability. The smaller the shrinkage rate of boiling water, the better the structural stability of the fiber, the more stable the size of the fiber in the process of processing and taking the wet heat treatment (such as dyeing, washing, etc.), the less deformation; At the same time, the physical and mechanical properties and dyeing properties are good. The boiling water shrinkage rate of the fiber is only controlled by the heat setting process conditions of the fiber.

9. Combustion performance

The flammability of fiber refers to how easily the fiber burns in air. International regulations adopt the "limiting oxygen index" method, referred to as LOI method. The so-called limiting oxygen index is the lowest percentage of oxygen in the nitrogen and oxygen mixture in the environment when the fiber is removed from the fire source and the fiber can continue to burn.

LOI and fibers are classified as follows.

① Combustible or flammable fibers with LOI < 21%

② Flame retardant or flame retardant fiber LOI > 21% of the fiber

③ Flame retardant fiber LOI > 26% fiber

A lot of research has been done on the flame retardant treatment of chemical fibers at home and abroad, mainly using copolymerization, blending, surface treatment and other methods to introduce organophosphorus compounds, organohalogen compounds or both in fibers or fabrics.

10. Wear resistance of fiber

Fibers and their products are worn due to constant friction during processing and actual use. The wear resistance of the fiber refers to the resistance of the fiber to external wear.

The wear resistance of fiber is closely related to the fastness of textile products. Wear resistance is an important index of wear performance of clothing fabric. The wear resistance of fiber is related to the macromolecular structure, supramolecular structure, elongation at break and elasticity of fiber.

The order of the wear resistance of common fibers is nylon > polypropylene > Vinylon > ethylene fiber > Polyester > Acrylic > Chlorylon > wool polysilk > cotton > hemp > rich fiber > copper ammonia fiber > viscose fiber > acetate fiber > glass fiber.

11. Light resistance and stability

The stability of the sunlight and the atmosphere is one of the stability indicators of the fiber, also known as weather resistance, which is a measure of the ability of the fiber to resist the performance changes caused by climatic conditions.

Light resistance refers to the mechanical properties of fibers that remain unchanged after exposure to light. The stability of the effect on the atmosphere refers to the performance of the fiber after being exposed to light, oxygen, heat and water in the air for a long time, without degradation or photooxidation, and without color change.

The light resistance of chemical fiber is related to the composition of molecular chain, the formation of main chain bond and crosslinking bond, the vibration energy and conversion of molecular groups, the aggregation structure of fiber, and the intensity of light radiation, irradiation time and wavelength.

The change of fiber properties caused by climate conditions is mainly caused by sunlight and oxygen in the air, so improving the stability of the fiber's light resistance to the atmosphere is to improve its light stability and oxygen stability.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands