Seventy years of great changes in the new era shoulder heavy responsibilities

In the past 70 years, China's printing industry has gone through an extraordinary road. Generally, it can be divided into five stages: In the thirty years after the founding of New China, it went through two stages. The first stage: supporting the construction of political power and establishing an industrial system (1949-1965); The second stage: Ten years of civil strife and difficult progress (1966-1976). After the crushing of the Gang of Four in October 1976, and before the Third Plenary Session of the 11th Central Committee of the Party in December 1978, China experienced another two years of "moving forward in limbo." Four decades of reform and opening up have gone through three stages: the first stage: new system, new thinking, promoting new development (1978-1999); The second stage: expanding opening up, deepening reform and accelerating development (2000-2007); The third phase: Addressing challenges, accelerating transformation and improving the quality of development (2008-2019).

First, support the construction of political power and establish an industrial system

(1949-1965)

The Communist Party of China has a tradition of attaching great importance to propaganda and printing. Printing is needed to propagate truth and mobilize the masses. From the founding of the Party in Shanghai to the establishment of the first Soviet regime in Ruijin, from Yan 'an, the holy land of the revolution, to Xibaipo, where the historic decision to "liberate the whole of China" was made, the Communist Party of China has always attached great importance to theoretical propaganda and printing work. After the founding of New China in October 1949, supporting the construction of the regime became an important and arduous task that China's printing industry must first undertake.

Old China left the printing industry with some dilapidated and old factories. According to local records, there were 280 printing enterprises in Beijing at that time, employing more than 2,900 people; There are 2,877 private printing enterprises in Shanghai, employing 28,880 people; There are only more than 70 private printing enterprises in Guangdong, employing 2,000 people. Most of the equipment is old and backward, mostly manual and pedal printing equipment. It is on this basis that we started to develop in the service of the new regime.

1, Renminbi printing: In February 1949, after the peaceful liberation of Beiping was the first to take over, the fastest to resume production of enterprises - Central printing factory Beiping factory printed the first batch of five yuan denomination of the new version of renminbi. In March 1950, the factory opened a new factory name approved by the People's Bank of China: Beijing People's Printing Factory, and in January 1955, the factory name of "State-owned 541 Factory" was opened, and Shanghai "State-owned 542 Factory" is a professional printing enterprise of RMB.

2. Newspaper printing: From the War of Liberation to the founding of New China, newspaper publishing and printing under the leadership of the Party has always been uninterrupted. By 1960, there were 1,274 types of newspapers published nationwide, an increase of 8.1 times compared with 1950 in the early days of the founding of New China, and the annual printing capacity reached 5.88 billion copies, an increase of 13.3 times.

3, publishing and printing: In October 1949, the Publishing Committee of the Publicity Department of the CPC Central Committee held the first National Xinhua Bookstore Publishing work conference. On November 1 of the same year, the General Administration of Publication of the Central People's Government was established.

From August to September 1950, the General Administration of Publications successively held the second working conference of the National Xinhua Bookstore and the first National Publishing Conference, proposing that the public and private printing industry should serve the people's publishing industry, and the printing factories operated by Xinhua bookstores in the war years should be divided into independent state-owned enterprises. In April 1951, the 12 state-owned Xinhua printing plants directly under the General Administration of Publications in Beijing, Shanghai and other places participated in the first national Xinhua printing factory working conference, accounting for about 17% of the printing production capacity of the country.

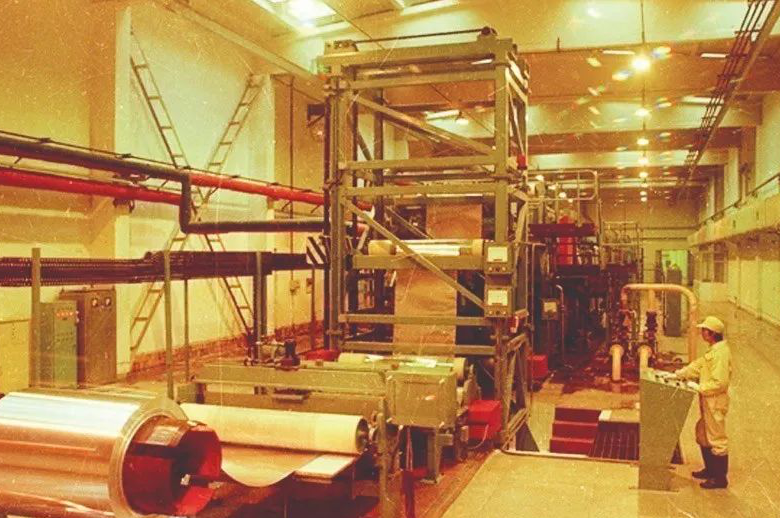

Xinhua printing factory old factory working scene

5, equipment and equipment industry synchronous development. In order to meet the needs of printing, in the closed environment at that time, the equipment and equipment industry also developed simultaneously. Through 17 years of self-reliance and hard work, it has basically formed an industrial system composed of printing, printing equipment and printing equipment. Although the level is not high, it has laid a certain foundation for the future development of the industry. In September 1949, the state-owned Shanghai People's Railway Factory was established, mainly producing two-rotary printing presses, folding machines, rotary newspaper printing machines and other products. In 1958, it merged with the Second Steel Machinery Factory to form the state-owned Shanghai People's Machinery Factory. In February 1951, Beijing People's Machine Factory was established, and in 1956, the first Ministry of Machinery Industry identified the factory as a professional manufacturer of printing machinery. In 1949, Tianjin Ink Factory was established, and China's first state-run ink factory appeared.

6. Establish research institutes and universities. Soon, Shanghai, Beijing and other places have established printing technology research institute. In order to train printing professionals, the state began to set up printing majors from the 1950s, and Shanghai Publishing and Printing College (1953) and Beijing Printing College (1958) were founded in succession during this period.

Beijing Printing Institute, the original culture college printing department internship factory

On a rather weak foundation, after 17 years of efforts, we not only ensured the demand for the printing industry in the construction of the political power, but also established a basically complete industrial system in the layout of enterprises and the national management level; A management system has been formed in which the General Administration of Publications is in charge of publication and distribution, the Light Industry Department is in charge of non-publication printing and papermaking, the first Machinery Department is in charge of printing equipment, and the Chemical Industry Department is in charge of ink (printing equipment).

Twenty or ten years of internal strife, hard to move forward

(1966-1976)

At that time, the management of enterprises fell into a serious state of confusion, taking the Beijing book printing industry as an example, its total industrial output value in 1970 was only 77% of that in 1965.

During the ten years of civil unrest, the majority of cadres and workers in the national printing industry struggled against the retrogression of the far-left line, and insisted on the production and operation of the printing industry, technological progress, the construction of backbone enterprises, and major technology research and development projects, which made a difficult start and carried forward under very difficult conditions. During this period, two things are particularly noteworthy:

First, the backbone of printing equipment manufacturing has been enhanced. From the late 1960s to the early 1970s, the printing machinery industry built two new large-scale professional manufacturing plants, and expanded and rebuilt eight medium-sized professional manufacturing plants. At this point, China's printing machinery manufacturing industry has initially formed four large-scale professional factories and more than ten medium-sized professional factories as the main body of professional manufacturing backbone forces with Beijing People's Machinery Factory, Shanghai People's Machinery Factory, Shaanxi Printing Machinery Factory, Hunan Printing Machinery factory. In 1973, the State Publishing Administration and the Ministry of First Machinery, the Ministry of Light Industry and the Ministry of Chemical Industry jointly formulated the "1974-1975 Printing Technology Transformation Plan" and proposed the development of 28 new product trial production tasks. This plan has received the attention of the State Planning Commission of The State Council. Among the 28 new products, such as high-speed newspaper rotary press, B-B offset press, wireless hot melt binding machine, hardcover book linkage production line and other general mechanical products were completed as scheduled, while 10 products such as electronic color separation machines with more complex technology and high degree of automation, such as electronic and optical products, failed to complete the trial production task. The completion of some new product trial production tasks laid a certain material foundation for the rapid development of China's printing industry in the 1980s.

The domestic monochrome proof press in the 1970s

In the 1970s, a large number of domestic two-color offset presses, full-sheet monochromatic letterpress rotary machines and book rotary machines were put into production. Many large and medium-sized printing plants in Beijing have purchased a large number of such equipment, and printing production has begun to change from low speed to high speed, monochrome to two-color. On December 6, 1973, the first color newspaper of the People's Daily was successfully printed and officially issued on January 1 of the following year. Color newspaper printing in China took its first step.

Second, the 748 project (Chinese character information processing system project) started. In August 1974, the Ministry of the fourth machinery, the Ministry of the first machinery, the Chinese Academy of Sciences, Xinhua News Agency, the State Publishing Administration five departments jointly submitted to the State Planning Commission and The State Council "on the development of Chinese character information processing system engineering request Report", requesting the Chinese character computer information processing project included in the national key scientific research project plan. This report has been highly valued by The State Council and the State Planning Commission. Premier Zhou Enlai of The State Council and Director of the State Planning Commission Yu Qiuli listened to the project report.

In September 1974, the State Planning Commission approved the letter No. 448 (74), agreeing to include the Chinese character information processing project in the national science and technology development plan, and tasked the fourth machine Department to be responsible for the specific organization and implementation, set up a special office in the fourth machine Department, and the Electronics Department appointed Guo Pingxin as the director of the office. The project was announced in August 1974 and is known as "Project 748". Since then, "748" has not only become an important milestone in the development history of China's printing technology, but also an important historical turning point in the development of China's computer information industry. "748 Project" opened the prelude to the second revolution in printing technology in China. Since 1975, Professor Wang Xuan has been engaged in the "748 project", that is, the development of Chinese character information processing system.

After two years of "moving forward in the wandering", marked by the victory of the Third Plenary Session of the eleventh Central Committee of the Party in December 1978, China's printing industry, together with all walks of life in the country, began to enter a new period of reform and opening up.

Third, new systems and new thinking to promote new development

(1978-1999)

Shortly after the reform and opening up, in the early 1980s, the development plan of printing technology and equipment was first included in the national development plan. In 1982, the Central Government made it clear that under the leadership of The State Council, the National Economic Commission took the lead in solving the problem of backward printing technology. In July of the same year, Zhang Jinfu, director of the State Economic Commission, presided over a meeting on the topic of "Revitalizing China's printing industry and changing the backward face". In August of the same year, the State Economic Commission decided to set up a coordination group for technical transformation of the printing industry, chaired by the Machinery Industry Adjustment Office of the State Economic Commission, and jointly formed a coordination group with relevant personnel from machinery, electronics, light industry, chemical industry, the State Publishing Administration (later transformed into the Press and Publication Administration), the Publishing Bureau of the Central Publicity Department, the Chinese Academy of Sciences and the State Planning Commission. With Fan Muhan and Lu Bing as principal and deputy leaders, they are responsible for planning, implementing and coordinating the technical transformation among various departments.

At the same time, the first cross-departmental and whole-industry chain printing association was established, and the printing industry took the first step in industry management. On December 12, 1984, the Secretariat of the Central Committee and The State Council listened to the report of the printing technology and equipment coordination Group to the United States and Japan, Deng Liqun and Zhang Jinfu pointed out at the meeting that strengthening the horizontal connection and industry management between printing and equipment processes can take the form of establishing an association. In December 1985, with the approval of the State Economic Commission, China Printing and Equipment Industry Association was formally established, and elected Zhou Peiyuan, a famous scientist and vice chairman of the National Committee of the Chinese People's Political Consultative Conference, as honorary president, and Fan Muhan, leader of the printing Technical equipment coordination Group of the State Economic Commission, as president. The establishment of China Printing and Equipment Industry Association is the first step of China's printing industry to industry management, marking the development of China's printing and equipment industry has entered a new stage.

The coordination group and the industry association jointly operate, on the one hand, grasp the breakthrough of key projects, and grasp the promotion of technological transformation of the industry. The 16-word development policy of "laser phototypesetting, electronic color separation, offset printing, binding linkage" was put forward, and various departments were organized to study and formulate the "65th" and "75th" development plan for China's printing technology and equipment. This is an initiative and practice to promote the development of the industry in the early stage of reform and opening up, from the planned economy to the market economy.

In 1982, the State Economic Commission decided to establish a printing technical equipment coordination group headed by Fan Muhan (first from the left)

On December 2, 1987, the Economic Daily computer laser phototypesetting system project officially passed the identification of the National Appraisal Committee and the acceptance of the National Acceptance Committee, announcing the birth of the world's first Chinese daily newspaper using computer laser screen group and full-page output. In 1995, more than 1,500 newspapers across the country adopted laser phototypesetting systems. In the mid-1990s, China's key book printing plants all adopted domestic laser phototypesetting systems, and China's printing industry entered the era of "light and electricity".

Through the joint operation of the coordination group and industry associations, the printing industry has experienced a revolution since the founding of New China. A round of technological transformation with the largest scale (261 technical transformation projects have been established), the most extensive scope (involving more than 200 printing and printing equipment backbone enterprises), the largest investment (total investment of 2.792 billion yuan) and the longest duration (after the "Sixth Five-Year Plan" to "ninth Five-Year Plan" four Five-Year plan), the production capacity and technical level of the printing and equipment industry have been greatly improved. It laid the foundation for the rapid development of the industry later.

Basic situation of technical transformation of printing and equipment industry in China

Fourth, expand opening up, deepen reform and accelerate development

(2000-2007)

After China joined the World Trade Organization (WTO) at the end of 2001, its national economy entered a stage of rapid growth. The Press Association conducted in-depth research and planned for a rainy day, and proposed in 1998 that "pre-press digital, networking; Multi-color printing, high efficiency; Exquisite and automatic after printing; The 28-word guideline of "high quality and serialization of equipment" has determined the development direction and focus of China's printing industry from three years to 2010 after the "Ninth Five-Year Plan", and has effectively promoted the development of China's printing equipment and equipment industry.

In this period, the development of the national printing industry appeared three remarkable characteristics:

1, In the capital market, overseas capital, private capital investment is active

Increased foreign investment: Foreign investment started in the 1990s and reached a climax at the beginning of this century; The investment was first concentrated in Shenzhen, which implemented the Special Zone policy, and then rapidly expanded to the whole Pearl River Delta, especially represented by Hong Kong investment, and gradually transferred the production base to the mainland. After 2000, many internationally famous printing enterprises set up wholly-owned or joint ventures in China. Including engaged in printing Donnelly, engaged in equipment manufacturing Heidelberg, HP, Gao Bao, Komori and so on. The influx of foreign capital has promoted domestic print exports. In 2002, the national printing and processing exports were 30 billion yuan, and Guangdong reached 20 billion yuan; At that time, there were more than 1,600 foreign-funded enterprises in Guangdong, accounting for about three-quarters of the country.

Active private enterprises: After the Party's 14th National Congress in 1992 clearly proposed the establishment of a socialist market economic system, private printing enterprises mushroomed. On the whole, private enterprises in Zhejiang, Jiangsu, Guangdong and other places started early and developed fast, and gradually grew a number of large-scale printing enterprises based on packaging business.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands