"China Accelerates towards Carbon Neutrality" Cement: A path to carbon reduction in the cement industry

The cement industry has also been promoting the development of emerging cement alternative technologies such as CO2-cured concrete. Carbon curing concrete technology is through the mineralization reaction between carbon dioxide and calcium and magnesium components in concrete, while achieving the storage of greenhouse gases and improving the strength and durability of concrete, thereby reducing the use of cement. However, the technology is still in the pilot stage and needs to be further scaled up. In addition, alternative clinker technology based on non-calcium carbonate is also the focus of future technological innovation in the industry.

At present, China's cement clinker ratio is 0.67, lower than the global average of 0.74. A noteworthy policy trend is that according to the National Standard No. 3 Amendment of GB175-2007 "Portland General Purpose Cement", which has been implemented since October 1, 2019, the 32.5 strength grade (PC32.5R) of composite Portland cement will be cancelled. After modification, four strength grades of 42.5, 42.5R, 52.5 and 52.5R will be retained. This is aimed at improving capacity utilization and product quality in the cement industry, but it will also increase the proportion of clinker used in the cement industry, thereby increasing the unit CO2 emission intensity. To meet this challenge, it is necessary to comprehensively consider the balance between carbon emission intensity and total clinker consumption under the premise of meeting the technical requirements of building construction, and solve it through technological innovation and breakthrough.

We are well aware that the cement industry is one of the major industrial industries with high hard-to-abate emission reduction, not only because cement has fixed process emissions, but also because the overall volume of the cement industry is large but the individual scale is small, and it is difficult to bear the high emission reduction cost due to the low absolute price. All of these have made it difficult for the cement industry to scale CCS and make significant breakthroughs in emerging cement alternative technologies. However, at the same time, due to the remarkable results of the current supply-side reform, the overall profit level of cement enterprises is good, the industry integration degree is improved, and it is in a period of healthy development, and it has the ability to plan ahead and vigorously promote technological innovation and grasp the opportunity period of low-carbon transformation.

Enlightenment to cement enterprises

Capture the business model change opportunities brought about by the low-carbon trend, and actively adapt to downstream trends: cement companies should rethink their product structure, partnerships and their value in the entire construction industry, assess the changes in demand of major downstream customers such as construction developers in a low-carbon environment, and layout new growth opportunities as soon as possible. For example, cement companies can consider promoting technology research and development and enterprise acquisition in the field of alternative building materials, and advance layout of new building materials, building information models, and prefabricated and modular building solutions that may appear in the downstream builders, combining production and building information models to expand more business possibilities downstream. For the future access to sustainable fuel sources (such as biomass), cement companies should be positioned as early as possible according to the characteristics of the region, because other industries will also participate in the carbon neutral race and also want to achieve carbon reduction targets through sustainable fuels.

Under the theme of high-quality development in the "14th Five-Year Plan", vigorously promote the operational transformation of "low-carbon + digital", and improve efficiency to the extreme: deeply understand the impact of the national carbon emission reduction target on the cement industry chain during the "14th Five-Year Plan", and actively carry out end-to-end carbon footprint assessment and emission reduction cost curve assessment; Combine digital operations with low-carbon transformation, using artificial intelligence and machine learning to reduce volatility and improve energy efficiency in the production process, and reduce energy consumption and carbon emissions while continuously improving operational efficiency. For example, a European cement producer achieved fuel savings of 6% by creating a self-learning model of the kiln heat curve to optimize the shape and intensity of the kiln flame. The leading cement companies of the future can outperform their competitors through "low-carbon + digital" operations.

Pay attention to the medium - and long-term impact of low-carbon trends on the ecology of the cement industry, and explore possible new opportunities for green growth: keep track of new materials, new processes and new emission reduction technologies and other fields, carry out pilot projects under the premise of conditions, and obtain the advantage of the first mover in the development of the industry. For the possible "green premium" of emerging green products in the industrial chain, by developing corresponding "low carbon and zero carbon product lines", we will win reputation from environmentally conscious customers. In the future, the ecology of the cement industry may be reshaped by the trend of carbon neutrality, and the way to turn crisis into opportunity is to lay out innovative technologies in advance.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

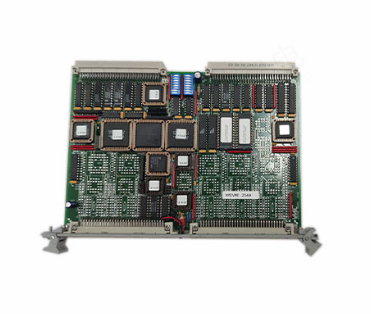

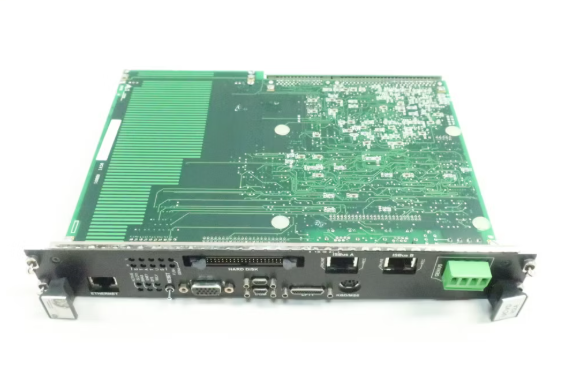

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com