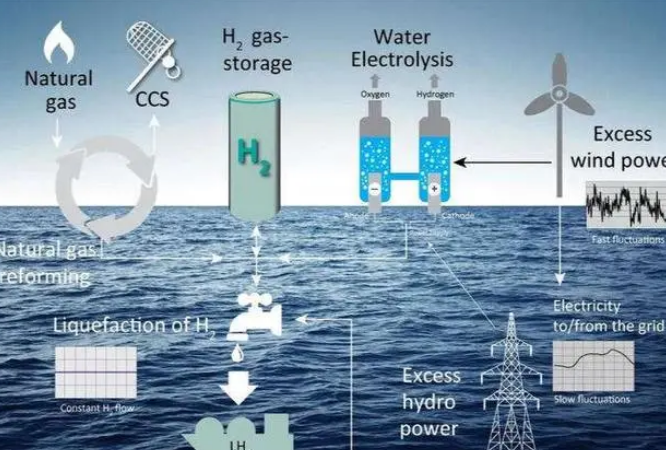

Hydrogen Production from renewable sources?

In addition, compared with the alkaline electrolyzer, the efficiency is low, only 70-80%, the polymer film electrolyzer PEM efficiency can reach more than 85%, the whole equipment is compact, the use of pure water, without alkaline electrolyte, the use of more safe and reliable. In addition, the polymer film electrolyzer PEM can be pressurized during the water electrolysis process, and can directly produce 3-4MPa hydrogen (and the volume fraction of hydrogen can reach more than 99.99%, which is easier to purify to the required purity of fuel cells).

In the past five years, the cost of the electrolytic cell has been reduced by 40%, but the high investment and operating costs are still the main problems to be solved in PEM electrolysis of water hydrogen production, which is closely related to the current oxygen evolution and hydrogen evolution electrocatalyst can only choose precious metal materials. Therefore, reducing the material cost of catalyst and electrolyzer, especially the noble metal load of cathode and anode electrocatalyst, and improving the efficiency and life of electrolyzer are the research focus of the development of PEM electrolysis water hydrogen production technology

2. Hydrogen production from biomass energy

Biomass energy hydrogen production has the following characteristics: mild reaction, low energy consumption, environmental friendliness, wide range of raw materials, renewable and so on. According to the U.S. Department of Energy, microalgae biofuel can replace the fuel of American cars. The quantum efficiency of microalgae converting solar energy is as high as 2-10% (compared to land plants <1%), and the growth rate of microalgae is extremely fast (the daily increase of biomass can reach 1-3 times).

At present, biomass energy hydrogen production is mainly considered from several directions: 1) genetic modification of fermentation hydrogen-producing bacteria to improve hydrogen production efficiency; 2) Hydrogen production through dark and light coupling fermentation; 3) Hydrogen production was increased by pretreatment.

Hydrogen production by fermentation of aquatic biomass such as microalgae has a strong industrial application prospect. In order to promote efficient and low-cost large-scale hydrogen production, some bottleneck problems need to be broken through:

① Promote the hydrolysis and saccharification of biomass waste such as microalgae efficiently and cheaply;

② The hydrogen production efficiency of dark fermentation bacteria was improved by genetic modification and strain domestication;

③ Hydrogen production efficiency and light utilization efficiency of photosynthetic fermentation of biomass were improved by reactor design and strain;

(4) Optimization of heat and mass transfer flow and coupling conditions in a continuous flow reactor coupled with dark light.

3, thermochemical cycle decomposition of water to produce hydrogen

The thermochemical cycle of splitting water to produce hydrogen is the process of using heat energy to split water into hydrogen and oxygen through a series of different but interrelated chemical reactions.

The thermochemical cycle decomposition of water for hydrogen production has the following obvious advantages: 1) low energy consumption (compared with electrolytic water and direct pyrolysis water, low cost); 2) It is easier to realize industrialization (mild reaction); 3) Can directly use the heat energy of the reactor, save the step of power generation, high efficiency; 4) In the thermochemical cycle, hydrogen and oxygen are usually produced in different reaction steps, so there is no need for high-temperature hydrogen-oxygen separation.

The thermochemical cycle decomposition water to produce hydrogen is usually evaluated by the cycle efficiency E (cycle efficiency E: the ratio of the high calorific value of hydrogen (285.8kJ/mol) to the total heat energy required by the cycle). In addition, other evaluation indicators: thermal efficiency, number of cyclic chemical reactions, side reactions, reactant toxicity, reactant price, reactant separation, corrosion problems, raw material handling problems, maximum reaction temperature and thermal conversion problems.

Thermochemical cycle reaction to produce hydrogen was originally proposed by J.E.Funk of the University of Kentucky in 1960, and its principle can be expressed by the following general formula of chemical reaction:

A and B in the formula are called cyclic reagents. The step heating method is used to make the reaction continue to cycle, so as to achieve the purpose of continuous hydrogen production.

In the early 1970s, McKeady and Beni proposed the Mark1 thermal-chemical hydrogen production scheme, and estimated that the efficiency could reach about 55%. The cycle first studied by Marcheltti and DeBeni at Ispra in Italy, called the Mark1 cycle, belongs to the halide system, but it is not suitable for large-scale industrial applications due to the highly toxic Hg involved in this cycle system. People later proposed that circulation systems such as Mark2, Mark3 and Mark6 had replaced the use of Hg, but the whole system was still too complex and not suitable for large-scale industrial application.)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands