ABB 1TGE120021R0110 Fieldbus unit module negotiation

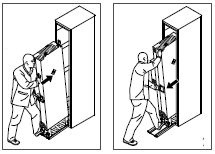

Push the drive module into the cabinet and pull it from the cabinet carefully

preferably with help from another person as shown below. Keep a constant

pressure with one foot on the base of the module to prevent the module from

falling on its back. Use safety shoes with metal toe cap to avoid foot injury.

Do not use the ramp with plinth heights which exceed the maximum height

marked on the ramp next to the fastening screw. (The maximum plinth height

is 50 mm when the telescopic ramp is shortest and 150 mm when the ramp is

longest.) Tighten the two fastening bolts of the ramp carefully

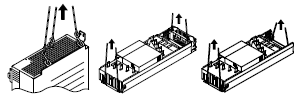

Handle the drive module carefully. Make sure that the module does not fall

down when moving it on the floor and during installation and maintenance

work: Open the support legs by pressing each leg a little down (1, 2) and

turning it aside. When ever possible secure the module also with chains.

- Do not tilt the drive module (A). It is heavy (over 160 kg [350 lb]) and its

center of gravity is high. The module will overturn from a sideways tilt of 5

degrees. Do not leave the module unattended on a sloping floor.

Beware of hot surfaces. Some parts, such as heatsinks of power

semiconductors, remain hot for a while after disconnection of the electrical

supply.

• Make sure that dust from borings and grindings does not enter the drive when

installing. Electrically conductive dust inside the unit may cause damage or

malfunctioning.

• Ensure sufficient cooling.

• Do not fasten the drive by riveting or welding.

WARNING! Ignoring the following instructions can cause equipment malfunction

and damage to the fiber optic cables:

• Handle the fiber optic cables with care. When unplugging optic cables, always

grab the connector, not the cable itself. Do not touch the ends of the fibers with

bare hands as the fiber is extremely sensitive to dirt. The minimum allowed

bend radius is 35 mm (1.4 in.)

Printed circuit boards

Safe start-up and operation

General safety

These warnings are intended for all who plan the operation of the drive or operate

the drive.

Permanent magnet motor drives

WARNING! Do not run the motor over the rated speed. Motor overspeed leads to

overvoltage which may damage or explode the capacitors in the intermediate circuit

of the drive.

WARNING! Ignoring the following instructions can cause damage to the printed

circuit boards:

• Wear a grounding wrist band when handling the boards. Do not touch the

boards unnecessarily. The printed circuit boards contain components sensitive

to electrostatic discharge.

WARNING! Ignoring the following instructions can cause physical injury or death,

or damage to the equipment:

• Before adjusting the drive and putting it into service, make sure that the motor

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at

speeds above and below the speed provided by connecting the motor directly

to the power line.

• Do not activate any automatic fault reset functions of the drive control program

if dangerous situations can occur. When activated, these functions will reset

the drive and resume operation after a fault.

• Do not control the motor with an AC contactor or disconnecting device;

instead, use the control panel keys and , or commands via the I/O

board of the drive. The maximum allowed number of charging cycles of the DC

capacitors, ie, power-ups by applying power, is five in ten minutes.

Note:

• If an external source for start command is selected and it is ON, the drive will

start immediately after an input voltage break or fault reset unless the drive is

configured for 3-wire (a pulse) start/stop.

• When the control location is not set to local, the stop key on the control panel

will not stop the drive.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands