Construction of comprehensive treatment of mine solid waste in the era of big data

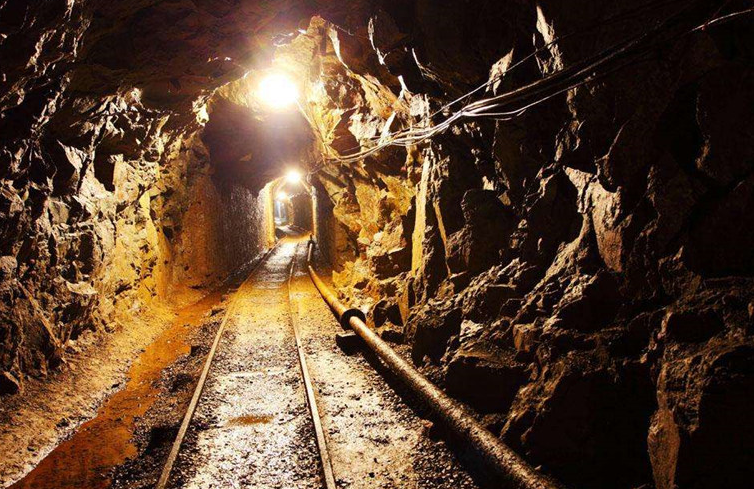

In recent years, with the rapid development of China's economy, the environment has been greatly damaged, we should adhere to the principle of economic development can not be at the expense of the environment, pay attention to environmental issues. One of the more important issues is the treatment of solid waste, and the main source of solid waste is the waste rock and tailings discharged by the mining industry, that is, the solid waste of the mine. Mine solid waste belongs to industrial solid waste, mainly refers to all kinds of mines in the construction of shafts and alleys, mining process, open pit mining process produced by the stripping and waste rock, and washing and smelting process produced by the tailings or waste slag.

The amount of stripping waste produced by mining in China is amazing, and the mining stripping ratio of mining is large, such as the mining stripping ratio of metallurgical mines is (2~4); The ratio of mining and stripping in straight mines is mostly 1: (2~8), and the highest is 1: 14. The maximum mining and stripping ratio of gold mines can reach 1:(10~14). The annual discharge of waste rock from mines in China exceeds 600 million tons, and the annual stripping of waste rock from open-pit iron mines alone reaches 400 million tons. The total amount of waste stone in our country has reached tens of billions of tons, which is the first country in the name of waste stone discharge.

The harm caused by solid waste is also very huge, mainly in the following aspects:

One is to pollute the environment around the mine. The minerals in the mine contain a large number of unknown pollutants before being treated, and the waste naturally contains excessive pollutants (such as radioactive elements, heavy metal elements, etc.). In the process of mine solid waste stacking, on the one hand, these pollutants will penetrate into the ground and pollute the surrounding soil and water sources; On the other hand, it will also react with other substances on the surface, forming new pollution. It is understood that in the total area of the land destroyed by mines in China, about 59% are destroyed due to the gob formed by mining,20% are occupied by open pit waste piles,13% are occupied by tailings ponds,5% are occupied by underground waste rock piles, and 3% are in the collapse danger zone. Among them, tailings and waste rock piles accounted for 38% of the total.

The other is soil erosion. Serious soil pollution will make the surface of the mine can not continue to grow vegetation, resulting in the surrounding soil increasingly loose, when the rain washed will form soil erosion. The third is to bring security risks. Mine waste is piled up in a disorderly manner, and the soil has become loose due to damage, so there may be a collapse or landslide phenomenon at any time. In recent years, the resulting disasters have occurred from time to time, such as landslide, debris flow, tailings dam break, etc., which not only destroyed the ecological environment, but also posed a serious threat to people's lives and property safety. On December 20, 2015, a huge landslide occurred at the Hongao Yu mud collection site in Guangming New District of Shenzhen, Guangdong Province, killing 73 people. After investigation, it was found that the main cause of the accident was the serious over-storage and ultra-high overfill in the receiving field, which led to this tragedy. In addition, due to the environmental deterioration caused by the stacked mine solid waste, the later restoration cost will also be greatly increased.

The fourth is the serious waste of resources caused by the massive discharge of mine solid waste. Mine solid waste often contains a variety of metal elements, if long-term stacking and loss, not timely recovery and comprehensive utilization, not only pollute the environment, but also for the national mineral resources is a great waste. The utilization rate of mineral resources in China is very low, its total recovery rate is 20% lower than that of developed countries, the average recovery rate of ferrous metal mining such as iron and manganese is only 65%, and the comprehensive recovery rate of non-ferrous metal mining in China is only 60%~70%. Taking iron ore as an example, there are more than 30 kinds of associated components in Chinese resources, but only 20 kinds can be recovered at present. Therefore, a large amount of valuable metal elements and available non-metallic minerals are left in solid waste, resulting in annual mineral resource development losses of about 100 billion yuan. Especially the old tailings, due to the restriction of the conditions at that time, the loss to the valuable group of tailings is greater. In 1997, the amount of gold mined in China was 25.4 million tons, the total recovery rate of gold was 86.46%, and about 18-20 tons of gold was lost in the tailings.

These are the main hazards of mine solid waste, it is like a time bomb, once activated, will cause a devastating blow to the environment. And this "bomb" is far from as simple as it seems, and its ingredients are extremely complex, so the actual consequences are far more than those listed. There is therefore an urgent need for action.

In 2005, the State Environmental Protection Administration, the Ministry of Land and Resources, the Ministry of Health issued the "Mining ecological environment protection and pollution prevention technology Policy", for the mine solid waste proposed to vigorously promote the comprehensive utilization of mineral processing solid waste technology, including: (1) tailings recycling and co-associated minerals and valuable elements recovery technology; ② The use of tailings processing production of building materials and products technology, such as cement additives, tailings brick, etc.; (3) Promote the technology of using tailings and waste rock as fillers to fill goaf or subsidence areas; (4) Using coal preparation slime to develop bio-organic fertilizer technology.

Let's talk about these aspects specifically :1. Recovery of useful metals from tailings. One of the products of separation operations in beneficiation, the part with the lowest content of useful target components is called tailings. Under the current technical and economic conditions, it is not appropriate to further improve sorting. However, with the development of production science and technology, the useful target components may also have the economic value of improving recycling. Tailings are not completely useless materials, often contain components that can be used for other purposes, and can be comprehensively utilized. Achieve no waste discharge. It is necessary to make full use of mineral resources and protect the ecological environment. The 11 tailings ponds of 7 large iron ore concentrators in a northeast region of China, with an annual discharge of 27 million tons of tailings, accumulated 770 million tons of tailings by May 2017, containing 8%~16% iron, and recovered iron concentrate (containing 54%~65% iron) and middle ore (containing 35%~40% iron) for cement plants as additives after the construction of the reconcentration workshop. The Nanyuan Iron Mine used the magnetic-gravity separation process to concentrate 5 million tons of tailings, and recovered 407,800 tons of iron concentrate with a grade of 56.71% and a recovery rate of 42.94%. Yongping Copper Mine daily treatment of 2000 tons of tailings, tailings by the combined process of heavy magnetic, heavy, floating and heavy separation step by step, the production of schetungstine concentrate 399.3 tons, sulfur concentrate 1584 tons, annual output value of 6.648 million yuan, annual profit of 1.728 million yuan; Dazhi Lvtongshan has recovered the tailings for many times. In the tailings after floating copper magnetic separation, iron concentrate is selected by the strong magnetic separation process and then the gold copper concentrate and iron concentrate with higher gold and silver content are selected by the re-grinding floating one weight one magnetic separation process. Gold copper concentrate 21.34g/t, silver 100g/t, copper 16.58g/t, the recovery rates were 64.81%, 18.16% and 53.66%, respectively. Some of the above successful cases we can learn from.

2. Use tailings to produce building materials

(1) Using tailings to make bricks. Iron tailings can be made into fire-free bricks, wall and floor decorative bricks. Maanshan Mine Research Institute has successfully made free brick by using iron ore tailings from Qidashan and Waitoushan. Jiangxi Copper Company Yinshan lead-zinc mine is used to produce autoclaved silicate brick because of its stable chemical composition of tailings. Dandong Institute of Building Materials used gold mine slag as the main raw material, adding some clay material with good plasticity, and made a new type of building decoration material - waste slag decorative brick by sintering. The use of copper and tungsten tailings to make bricks has also been successfully developed.

(2) The use of tailings to produce cement. Cement is made by two grinding and one firing process, and the strength of cement depends on the firing of clinker and the mineral composition in the clinker. Clinker is generally composed of tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium ferroaluminate, among which tricalcium silicate and tricalcium aluminate play an important role in the early strength of cement. Dicalcium silicate, tetracalcium ferroaluminate and tricalcium silicate played an important role in the later strength. Tricalcium silicate is the main mineral in cement clinker (about 50%). Tailings are used to produce cement, which is to use some trace elements in tailings to affect the formation of clinker and mineral composition.

(3) The use of tailings to produce new glass materials. Using high iron and aluminum tailings as the main raw material, the surface glass made by melting is black, shiny and uniform, no bubbles, no defects. (4) The use of tailings to produce building glass-ceramics. Tailings glass-ceramics granite was made from Damiao Iron Mine tailings and waste rock. The compressive strength, flexion strength, gloss and acid-alkali resistance of the finished products reached or exceeded that of natural granite. Using copper tailings as the main raw material, the glass-ceramics of copper tailings with high strength, wear-resistance and corrosion resistance have been developed through industrial tests to replace marble, granite and ceramic tiles. In addition, the use of tungsten tailings to develop glass-ceramics. (5) Use tailings to produce other building materials. Using the tailings of Dagushan concentrator mixed with cement, lime and other raw materials, the aerated concrete is made with light weight and good moisture retention. In addition, iron tailings can be used as basic materials for roadbed in large quantities.

3. Backfill the mined-out area with tailings. The tailing is fine and uniform in size. It has the advantages of convenient transportation, no processing and easy cementation when used as filling material in underground stope. The backfilling of tailings can greatly reduce the footprint. Conventional hydraulic filling (including high-concentration filling) uses graded coarse tailings. As a filler; The all-tailing paste filling technology developed in recent years has a remarkable effect on reducing or eliminating tailing pollution to the surface or underground environment. Waste rock is used as underground filling: one is direct backfill, the waste rock in the upper middle section is directly poured into the goaf in the lower middle section, most mines have adopted this backfill method; The other method is to lift the waste rock to the surface, carry out appropriate crushing processing, and mix the tailings and cement to backfill the goaf. This method is safe, but the processing cost is high. In Zhaoyuan Gold Mine and Jiaojia gold mine in Shandong province, China, the method of backfilling gob with mixed cement is adopted.

4. Other uses of tailings. There are some trace elements required by plants in the tailings, and the tailings can be directly processed as micro-fertilizer, or used as a soil amendment. For example, potassium, manganese, phosphorus, zinc, tin and other components in the tailings may often be micronutrient components of plants. The door tailing contains calcite, feldspar or alum salt, which can produce flocculant and collector of industrial sewage. Granodiorite tailing to produce flocculant or water glass is widely used in industry. In addition, the tailings can also be used as pesticides for agricultural production.

5. Start from the source, carry out comprehensive utilization of resources, and reduce the production of solid waste. Start from the source, carry out the comprehensive utilization of primary resources to reduce the production of solid waste, especially the production of fine tailings. It is an effective and economical method. Therefore, in the process design and production practice, in addition to improving the recovery rate of the main elements in the ore, it is also necessary to consider the comprehensive recovery of the associated metal elements and non-gold elements to avoid the tail project behind the main process. For the composite polymetallic ore whose comprehensive recovery technology is not mature, the resource reserve method can be adopted to be exploited when the conditions are mature to avoid the waste of resources.

In fact, the comprehensive treatment of mine solid waste can not be completed by enterprises on the one hand, but also requires efforts from all aspects. First, we must adhere to the principle of developing mineral resources under protection and protecting them during development, raise the people's awareness of resources and the environment, and integrate environmental protection into the whole process of resource development and utilization; The second is to incorporate the pollution prevention and control of mine solid waste into the overall planning of comprehensive remediation of mine ecological environment, guided by the principles of ecology and ecological economics, to coordinate resource development, comprehensive utilization of solid waste and pollution prevention, to economic and social development and environmental protection and construction of mining areas as objects, through unified planning and comprehensive construction, to achieve ecological construction, environmental construction and mining areas Coordinated development of economic construction; The third is to adapt to local conditions, according to the actual situation of each mine, adopt a reasonable way to comprehensively control the environmental pollution caused by solid waste, such as the reclamation and greening of solid waste dumps, the suppression of tailings pond dust, and the treatment of acid water discharged by solid waste. In a word, I believe that through the efforts of all parties the solid waste from mines can be well managed.

Over the years, especially in recent years, people have realized that tailings treatment and disposal technology is a worldwide problem, the whole tail overall utilization technology has made progress, no waste or less waste mining technology of mines continue to emerge, the use of tailings to make building materials production products are increasingly recognized by the society, become the bright spot of new productivity, the development of non-mineral mining industry is increasingly trapped around the mine solid waste generation The characteristics, combined with the market needs to develop new products, high value-added products are becoming the pursuit of the hot spot, the comprehensive utilization of solid waste in China has a certain technical basis, we should follow the focus of solid waste resources industrialization, select waste composite materials, tailings glass-ceramics, new lightweight building materials and useful minerals and metal extraction and other products technology, the establishment of batch Representative industrial demonstration projects with high technical starting point, significant comprehensive benefits and able to reach a certain scale, gradually form applicable and advanced complete sets of resource-based equipment and processes, and establish complete management methods and technical standards; According to the requirements of resource utilization, minimum quantification and harmless management, a management system for the overall utilization of mine tailings should be established to promote the industrialization of the overall utilization of mine solid waste. Mining enterprises should also further emancipate their minds, establish a solid waste management and operation mechanism that is in line with the market economy, raise funds in many ways, realize enterprise management, take the road of industrialization, and strive to practice the "three represents", develop our country's mining economy and improve our mining environment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands