Smart mine solutions and their successful applications

0 1 Overview

1.1 Background

At present, China's national economy has shifted from a stage of high-speed growth to a stage of high-quality development, and is in a crucial period of transforming the development model, optimizing the economic structure, and replacing old growth drivers with new ones. Under the situation of the deep integration of the "two modernizations", the industrial field is ushering in great changes in industrial development. The rapid development of the Internet and artificial intelligence technology has brought subversive changes to many traditional industries. The integration of high-tech with traditional technical equipment and management to achieve industrial transformation and upgrading is becoming an increasingly important development trend. It is in this context that smart mines are proposed and rapidly developed.

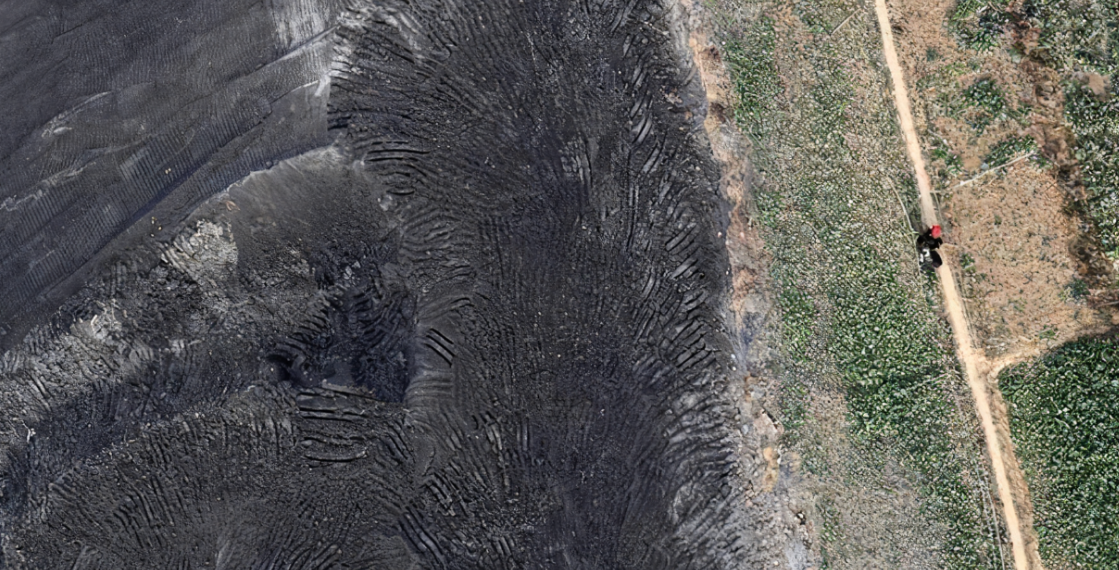

Mining coal resources is a production activity carried out by human underground. In order to create a safe and reliable mining environment suitable for equipment operation and personnel work, more than 90 subsystems such as detection, ventilation, drainage, fire prevention, power supply, working face mining equipment and transportation need to be operated at the same time. These subsystems, like the organs of the human body, together form a large-scale complex operating system. After years of development, this system has experienced mechanization, single machine automation, integrated automation, digital and other stages. At present, the mechanization degree of coal mine safe and efficient mine system has reached more than 90%, and the single machine automation has become increasingly perfect, and a number of tens of millions of tons of mine groups have been built, and a primary multi-system digital mine integrated automation system has been developed. However, at present, the overall degree of informatization in coal mines still needs to be further improved, and various data and information in the production process cannot be effectively related, and there is also a lack of "intelligent brain" to coordinate and jointly control all subsystems, so the production process control, equipment health management, safety risk prevention and control, ecological environmental protection, etc., have not yet achieved optimal management and control.

Wisdom is the highest form of mine technology development, only by realizing wisdom can we fundamentally realize the optimal production mode, the best operating efficiency and the safest production guarantee.

Since March 2016, The National Development and Reform Commission, the National Energy Administration, and the Ministry of Natural Resources have successively issued numerous programmic documents such as the Action Plan for Energy Technology Revolution and Innovation (2016-2030), the National Mineral Resources Plan (2016-2020), the 13th Five-Year Plan for Coal Industry Development, and the 13th Five-Year Plan for Safe Production. The guidance requirements for mine automation, informatization, digitization and intelligence are put forward respectively, and the direction for the future green development of mining enterprises is pointed out.

Based on the above analysis, it can be clearly seen that the construction of smart mines is the development trend and inevitable direction. Smart mining is to promote the comprehensive application of a new generation of network information technologies such as cloud computing, big data, Internet of Things, artificial intelligence and mobile communication in the field of mining on the basis of mine automation, information technology and digitization.

1.2 Definition of smart mine

Scholars have carried out a lot of research on smart mines, not only scholars and enterprises related to the coal field actively participate in the research and application of smart mines, a large number of non-coal mine enterprises and researchers have also joined the construction of smart mines. They each put forward various definitions and structures of smart mines according to their own understanding, research basis and expertise, but did not reach a unified understanding.

Comprehensive research results of scholars at home and abroad, combined with our many years of experience in the field of mining, we believe that: smart mine is the comprehensive application of intelligent industrial Internet of things and software-defined technology in the field of mining, is a typical Cyber Physical system (CPS). By integrating advanced information technology such as perception, calculation, communication and control and automatic control technology, the complex system of safety and production factors such as human, machine, environment and pipe mapping, timely interaction and efficient collaboration between the mine physical world and the information world is built.

The smart mine has four characteristics, namely, the interconnection of everything, spatio-temporal service, integration and linkage, and intelligent decision-making.

(1) Internet of Everything: The use of Internet of Things technology to fully perceive the position and status of underground people, machines, rings, etc., and can control the equipment.

(2) Time and Space service: GIS and BIM technologies are used to build a comprehensive mine database based on unified data standards, with spatial and geographic location as the main line, layer management as the organizational form, and the goal of creating a 5D digital twin for mines. Provide services and tools such as two-3D integrated location services, collaborative design services, configuration services, 3D visual simulation, mining engineering and equipment life cycle management for smart mine applications, to achieve a map integration and fusion, a map collaborative design, a map collaborative management and a map decision analysis.

(3) Fusion linkage: Through software definition, the data fusion and intelligent linkage of all business systems above and below the well are realized, and the strong real-time correlation of human, machine, environment and management information is achieved.

(4) Intelligent decision-making: The use of big data and artificial intelligence and other technologies to iteratively upgrade the intelligent analysis and auxiliary decision-making of coal mine safety, production and management.

02 Smart mine overall structure

Smart Mine Internet of Things Open Platform (RED-IOT®) is a smart open sharing platform developed by Huaxia Tianxin for the construction of smart mines in China, and is the top-level design of smart mines. Based on the software-defined concept of open sharing, RED-IOT® integrates GIM (GIS+BIM) space-time map, industrial Internet of Things, cloud computing, big data, artificial intelligence, mobile Internet, virtualization, network communication and other technologies to deeply integrate mine informatization and automation. It can complete accurate real-time collection of all data of mining enterprises, highly reliable network transmission, standardized integration, visual display and real-time dynamic analysis, and realize production process automation, safety monitoring digitization, data application modeling, production management visualization, and intelligent process control. And the hidden dangers, failures and danger sources of human-machine-environment are predicted in advance, prevention and emergency joint disposal, so that the whole mine has self-learning, analysis and decision-making ability.

The overall architecture of smart mine is based on the four-layer architecture system of Huaxia Energy Industrial Internet of Things, which is mainly composed of the perception implementation layer, the network transmission layer, the smart mine operating system platform layer (RED-MOS) and the intelligent application APP layer (RED-AppStore).

(1) Perception and execution layer: Using the Internet of Things technology, it can fully perceive the position and status of underground people, machines, rings, etc., and can control the equipment.

(2) Network transmission layer: mine wired and wireless transmission network, in addition to the security monitoring system independent networking, other systems are using the field bus fusion networking mode, on the basis of network resource unified protocol to achieve efficient and reliable data transmission.

(3) Smart Mine Operating System platform layer (RED-MOS) : It is an open and scalable smart mine kernel and operating system based on the mine cloud data center, which realizes the access of various sensing data downward and provides services and tools for the development of smart mine APP upward.

(4) Intelligent application layer (RED-AppStore) : It can realize the integration of automation and information application for mine production, safety, operation and management, and decision analysis, and realize mobile Internet applications and services based on intelligent terminals. Finally, the integration, intelligent linkage and dynamic expansion of application resources are realized, and data management, decision making and service are truly achieved.

In short, smart mine construction forms a comprehensive smart mine management and control platform for enterprise safety, production and operation management through vertical penetration, horizontal correlation, comprehensive integration and fusion innovation of each subsystem. The platform can operate safely, stably and reliably as a whole, and the subsystems can also operate independently. The failure of the platform shall not affect the operation of the subsystems, and the failure of the subsystems shall not affect the operation of the platform.

0 3 Smart mine operating system platform

The company has successfully developed the intelligent Mine operating System platform (RED-MOS) against the industrial Internet of Things platforms of ABB, Siemens and other internationally renowned enterprises. Smart mine operating system platform (RED-MOS) is the core of smart mine construction, which not only realizes the integration and fusion of multi-source heterogeneous sensing data, opens up the barrier between sensing data and intelligent applications based on sensing data, but also realizes the deep integration of informatization and automation in one platform, providing technical support for the energy industry to realize the integration of the two. As shown in Figure 3. In October 2018, the platform passed the scientific and technological achievements appraisal of the China Coal Industry Association, and the appraisal jury was composed of academician Liu Yunjie, an expert in the field of network and industrial Internet of Things, and Academician Wang Guofa, an expert in the field of domestic mining and smart mining, and other experts. The expert committee unanimously agreed that the platform reached the international leading level and filled the domestic gap.

3.1 Main platform functions

Through built-in platforms and tools, smart mine operating system platform provides data integration services, spatio-temporal location services, visual display, collaborative design, business process automation, big data analysis and other platform services and tools for smart mine applications of group, coal industry and mine end management:

(1) Data integration service: Through the real-time data integration service platform and back-end as a service platform, a full series of integrated services such as real-time safety production monitoring and monitoring data and mining business data collection, storage, query, statistics, subscription and push are provided, laying the foundation for data fusion linkage and big data analysis.

(2) Spatio-temporal location service: Through RED-GIS service platform and GIM spatio-temporal map platform, a comprehensive mine database based on unified data standards, with spatial and geographic location as the main line, layer management as the organization form, and the goal of creating a 5D digital twin of mines is built to provide full-time and global spatio-temporal location services for smart mine applications.

(3) Visual display tools: Through RED-GIS service platform, GIM spatio-temporal map platform, configuration platform and BI and report service platform, it provides rich visual display tools such as 2D and 3D integration, configuration graphics and custom visual components for smart mine applications.

(4) Collaborative design: Data sharing and collaborative design of geology, surveying, hydrology, mining, power supply, production and other departments are realized through GIM time-space map platform, collaborative design and workflow engine.

(5) Business process automation: Through the design of collaborative platform, back-end as a service platform, big data analysis service platform and workflow engine, the collaborative management and automation of business processes are realized, laying the foundation for intelligent decision-making and automated operation of major production links such as mining, excavation, transportation, ventilation, air pressure, drainage and power supply.

(6) Big data analysis services: Through real-time integrated data service platform, back-end as a service platform, BI and report service platform and big data analysis service platform, intelligent mining business services, real-time early warning of equipment failures and major hidden dangers, active prevention and emergency handling and linkage are realized, laying the foundation for the creation of efficient and intrinsically safe mines.

3.2 Main Features of the platform

Intelligent Mine Operating System Platform (RED-MOS) is an open and scalable intelligent mine core system based on cloud computing, with the following characteristics:

(1) The system design idea of "one platform + multiple industrial applications" is adopted. Through cooperative scheduling and elastic scaling technology, distributed data sharing and synchronization technology, network integration technology, high-performance service orchestration technology and container virtualization technology with isolation function and resource control function, a multi-level hybrid architecture of microservices for mining application research and development is constructed.

(2) Through the built-in platform and tools, it provides data integration services, spatio-temporal services, visualization services, collaborative design services, business process services and big data analysis services for the smart mine application subsystem, providing support for the ultimate realization of the interconnection of everything in the mine, platform integration, system linkage and intelligent operation.

(3) It provides strong support for big data analysis. Support full-dimensional data management, realize the docking with the computing framework, visualization and data application iteration of big data analysis, and ensure the effective operation of big data analysis.

(4) Software-defined network technology is adopted to improve the manageability and controllability of the smart mine network system and the security of network services, prevent and block illegal network intrusion and attacks, and reduce the cost of network system integration and operation and maintenance.

(5) High performance and strong real-time transmission control technology (RED-DDS) is adopted to realize the remote and strong real-time control of the smart mine operating system, which meets the requirements of interoperability, scalability and collaborative processing of distributed equipment in the construction of smart mine.

(6) The technology of full-time global data association and display is creatively built into the RED-MOS platform, which can provide dynamic and real-time spatial location services for personnel, equipment, sensors, etc., in smart mines.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands