GE Grid Solutions 350 Feeder Protection System

distribution feeders, as well as small- and medium-sized motors, transformers, generators and distribution buses.

Featuring small size, extractable, various protection and control functions, and rich communication protocols,

it can communicate and integrate with other devices in various ways to facilitate monitoring and control of power systems.

GE Grid Solutions 350 Feeder Protection System

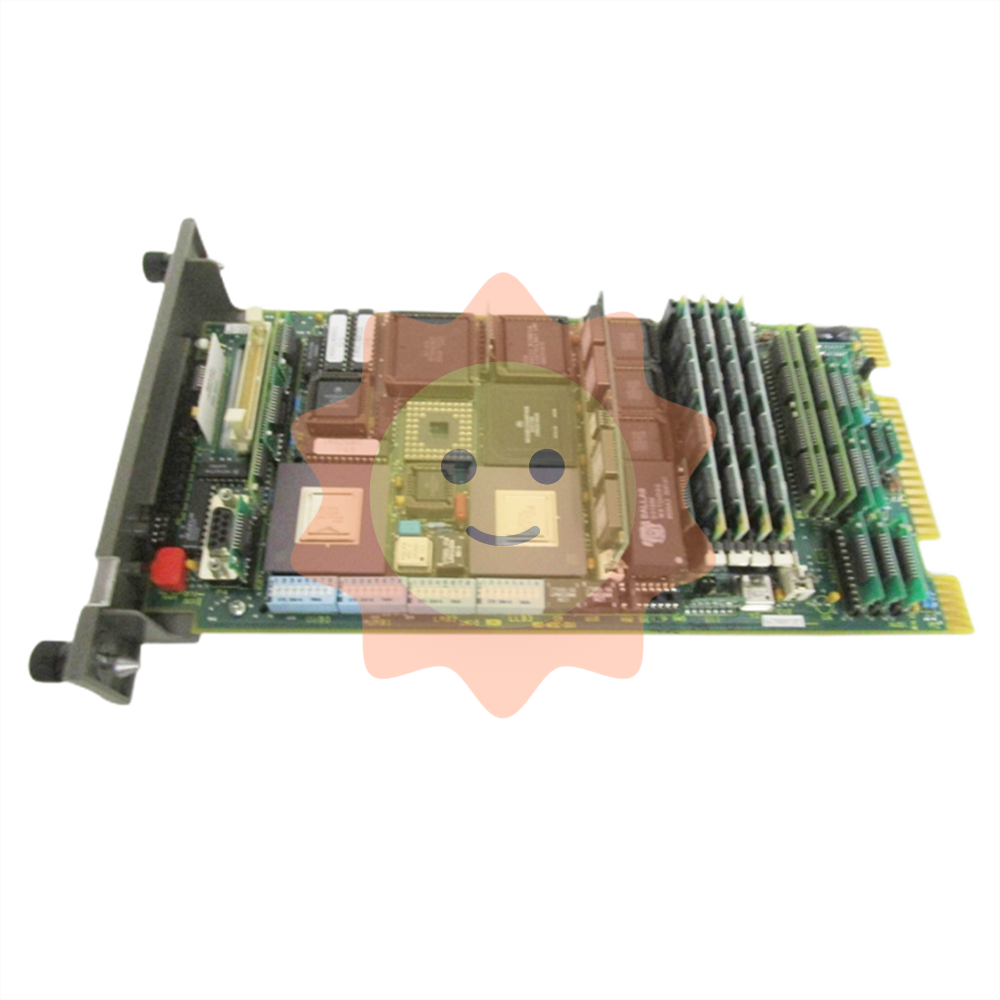

Product Overview

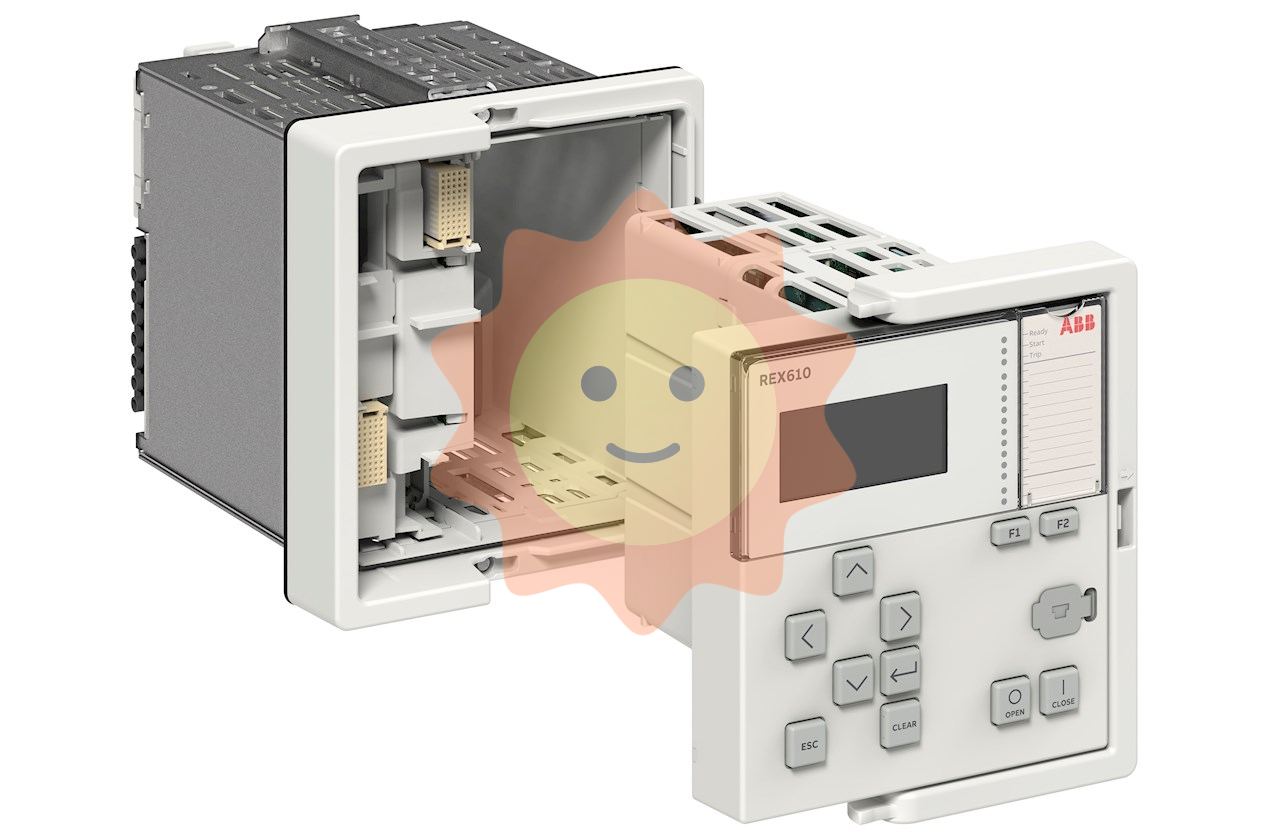

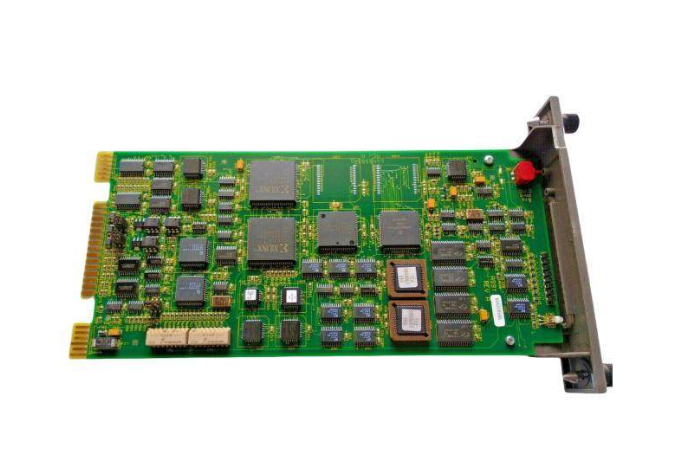

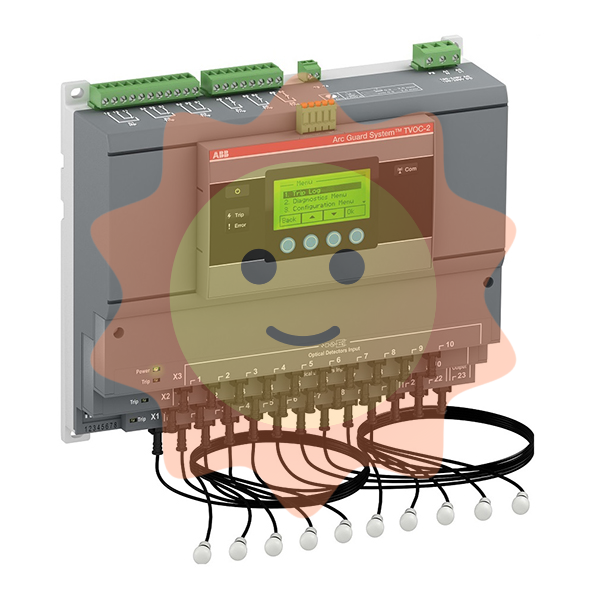

The 350 Feeder Protection System is a microprocessor-based relay for primary and backup overcurrent protection of low- and medium-voltage

distribution feeders, as well as small- and medium-sized motors, transformers, generators and distribution buses.

Featuring small size, extractable, various protection and control functions, and rich communication protocols,

it can communicate and integrate with other devices in various ways to facilitate monitoring and control of power systems.

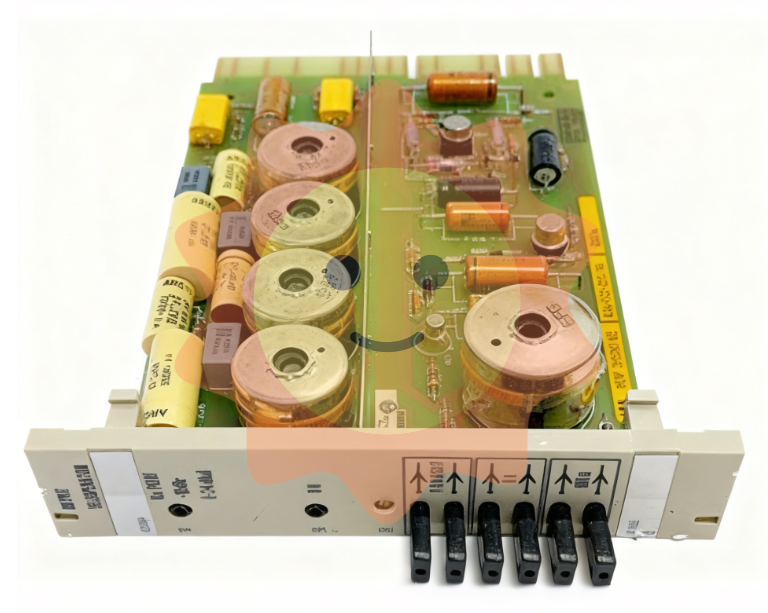

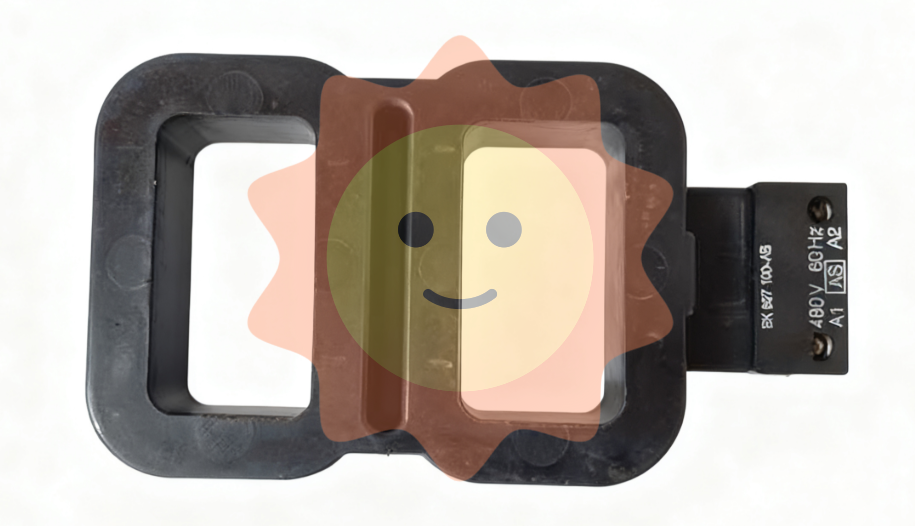

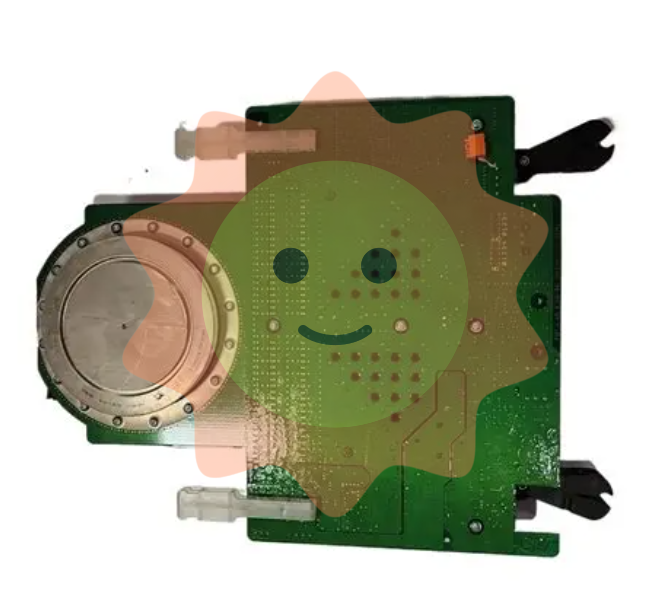

Installation Guide

Mechanical Installation: Introduces the dimensions of the device, product identification, steps and precautions for different mounting methods

(standard panel mounting, mounting using an adapter plate), as well as plug-and-play operation of the withdrawable unit,

IP20 protective cover mounting, and mounting methods for the arc flash sensor.

Electrical Installation: Covers typical wiring diagrams, terminal identification, wiring ranges, phase sequence and transformer polarity requirements,

as well as detailed descriptions of electrical connections for current, voltage, control power, contact inputs, trip and close output relays,

serial communications, and more.

Specification Parameters

1, protection function parameters: covering a variety of protection functions, such as overcurrent protection,

different types of overcurrent protection (phase overcurrent, ground overcurrent, etc.) with different pickup (Pickup) and dropout levels,

time delay and curve settings; undervoltage, overvoltage protection for different types of voltages (phase voltage, neutral voltage, etc.) with

the corresponding pickup and dropout voltage settings, time delay can also be adjusted; frequency protection for overfrequency

and underfrequency to set a specific pickup frequency and time delay; frequency protection for overfrequency and underfrequency

to set a specific pickup frequency and time delay.

The undervoltage and overvoltage protection has corresponding pickup and dropout voltage settings

for different voltage types (phase voltage, neutral voltage, etc.), and the time delay can also be adjusted.

In addition, there are protection functions for special faults, such as phase break detection,

power direction protection, etc., each with its own corresponding parameter settings.

2, measurement and metering parameters: can accurately measure a variety of electrical quantities,

including current (each phase, neutral, grounding, etc. current), voltage (each phase, neutral, auxiliary voltage, etc.),

power (active, reactive, apparent power), energy (positive and negative watt-hour, spent time), power factor, frequency, etc.,

and each parameter has the corresponding accuracy and range. For example, the three-phase active power measurement accuracy is ±1% of full scale,

resolution is 0.1MW, and the range is ±100000.0kW.

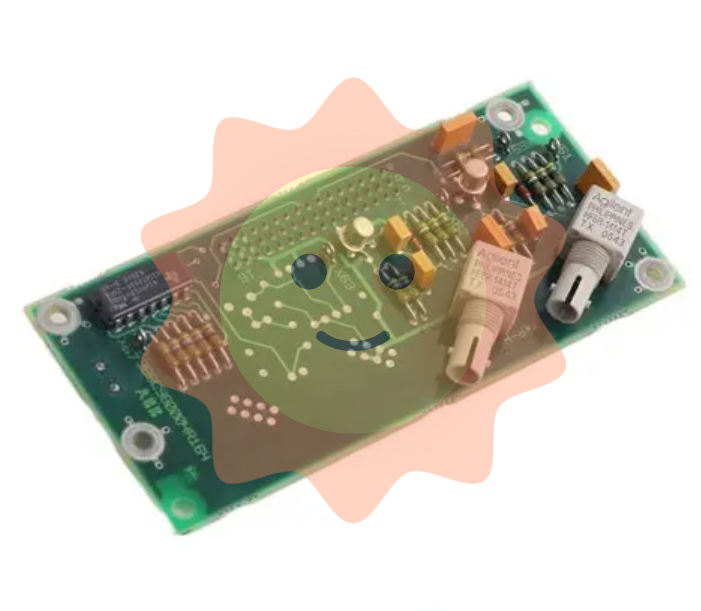

3, communication parameters: with a variety of communication interfaces, such as RS485, Ethernet, USB, etc.

The RS485 port supports a variety of baud rates and protocols, the Ethernet port supports different connection types and protocols,

and can also be configured with parameters such as IP address, subnet mask, etc., in order to meet different communication needs.

4, other parameters: power supply, there are different voltage ranges to choose from; physical characteristics, specify the size and weight of the device;

environmental adaptability, specify the operating temperature, altitude, pollution levels and other conditions .

Performance Advantages

1、Comprehensive protection ability: with rich protection functions, it can provide all-round protection against various power failures.

Different types of overcurrent protection can effectively deal with overcurrent situations of different degrees and locations;

under-voltage and over-voltage protection can safeguard the safety of the equipment in case of voltage abnormalities;

frequency protection can prevent system frequency abnormalities from damaging the equipment; and special fault protection functions can detect

and deal with special situations such as phase breaks, power direction abnormalities, etc., which greatly improves the safety and stability of the power system.

2, accurate measurement and monitoring: high-precision measurement capability makes the monitoring of power system operation status more accurate.

Through real-time monitoring of various electrical quantities, abnormalities in the system can be detected in time,

providing a reliable basis for fault diagnosis and prevention, helping to optimise the operation and management of

the power system and improve the quality of power supply.

3, flexible communication and configuration: a variety of communication interfaces and rich communication protocols,

so that it can be seamlessly connected and communicated with a variety of devices, convenient to achieve remote monitoring and centralised management.

Flexible configuration options can be customised according to different application scenarios and needs,

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

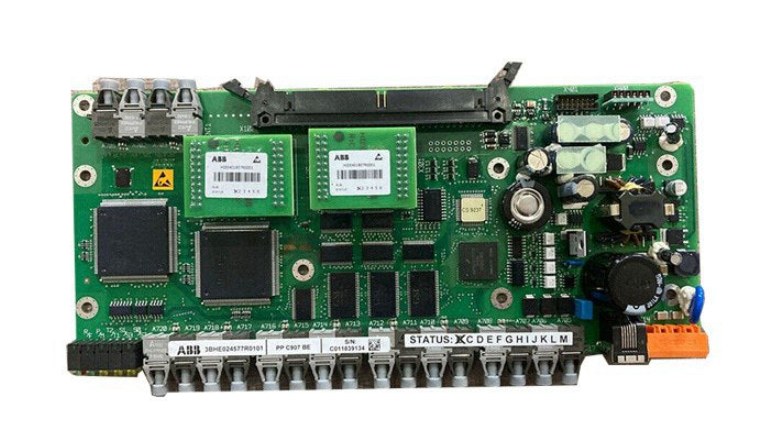

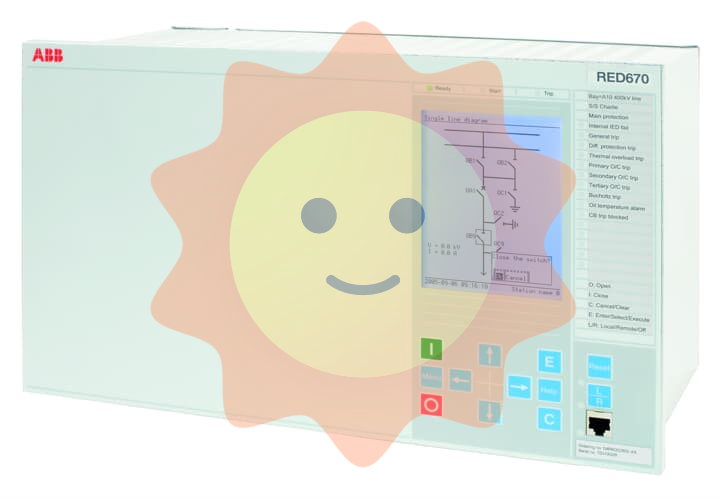

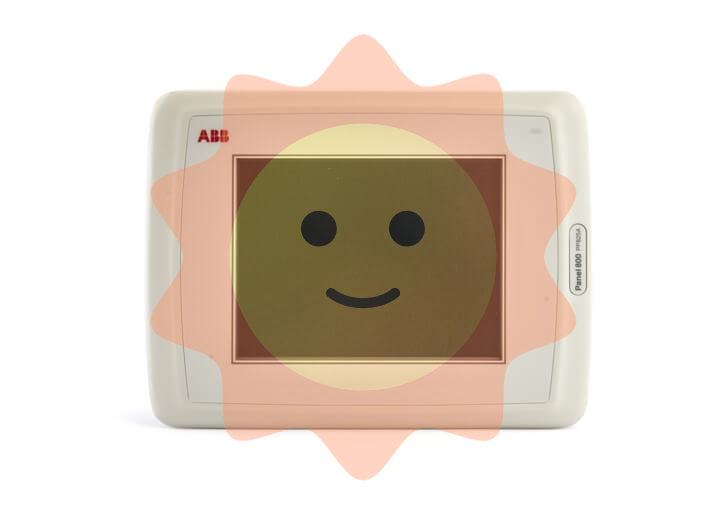

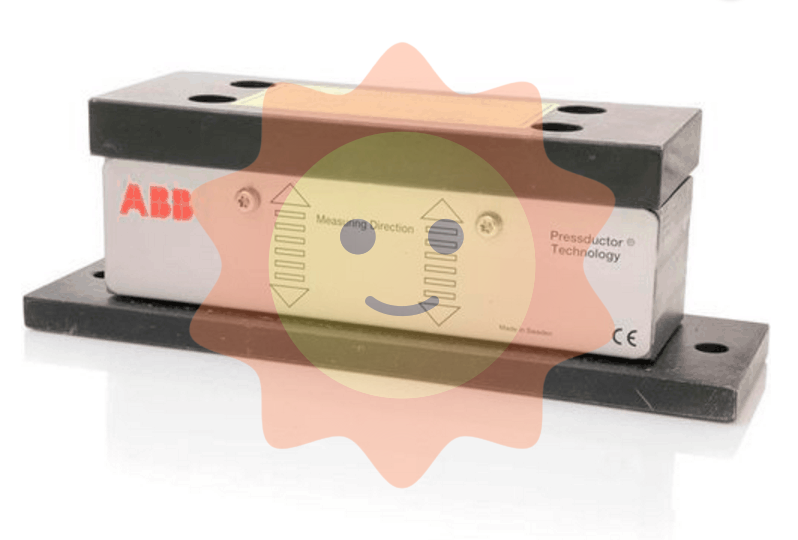

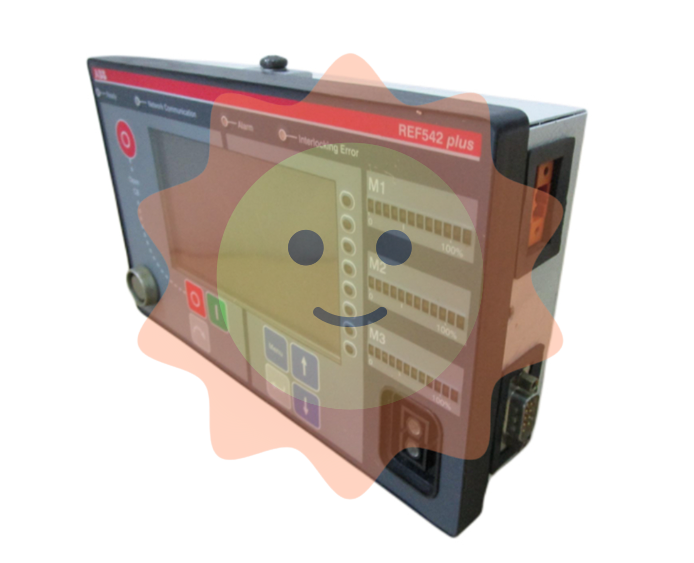

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

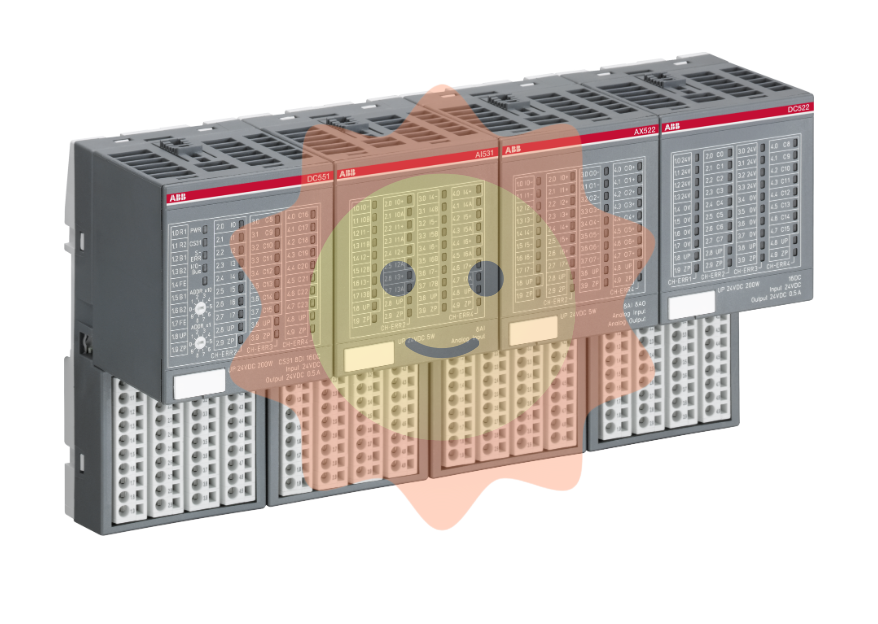

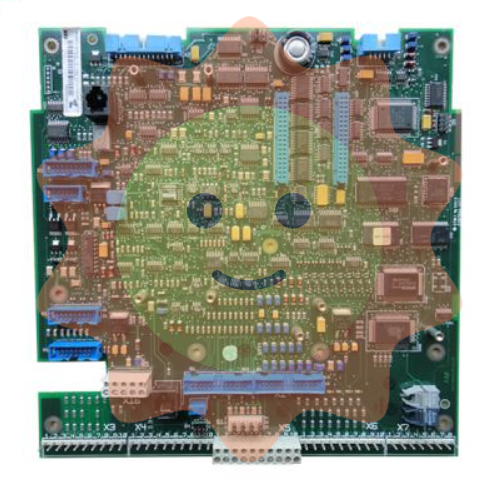

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com