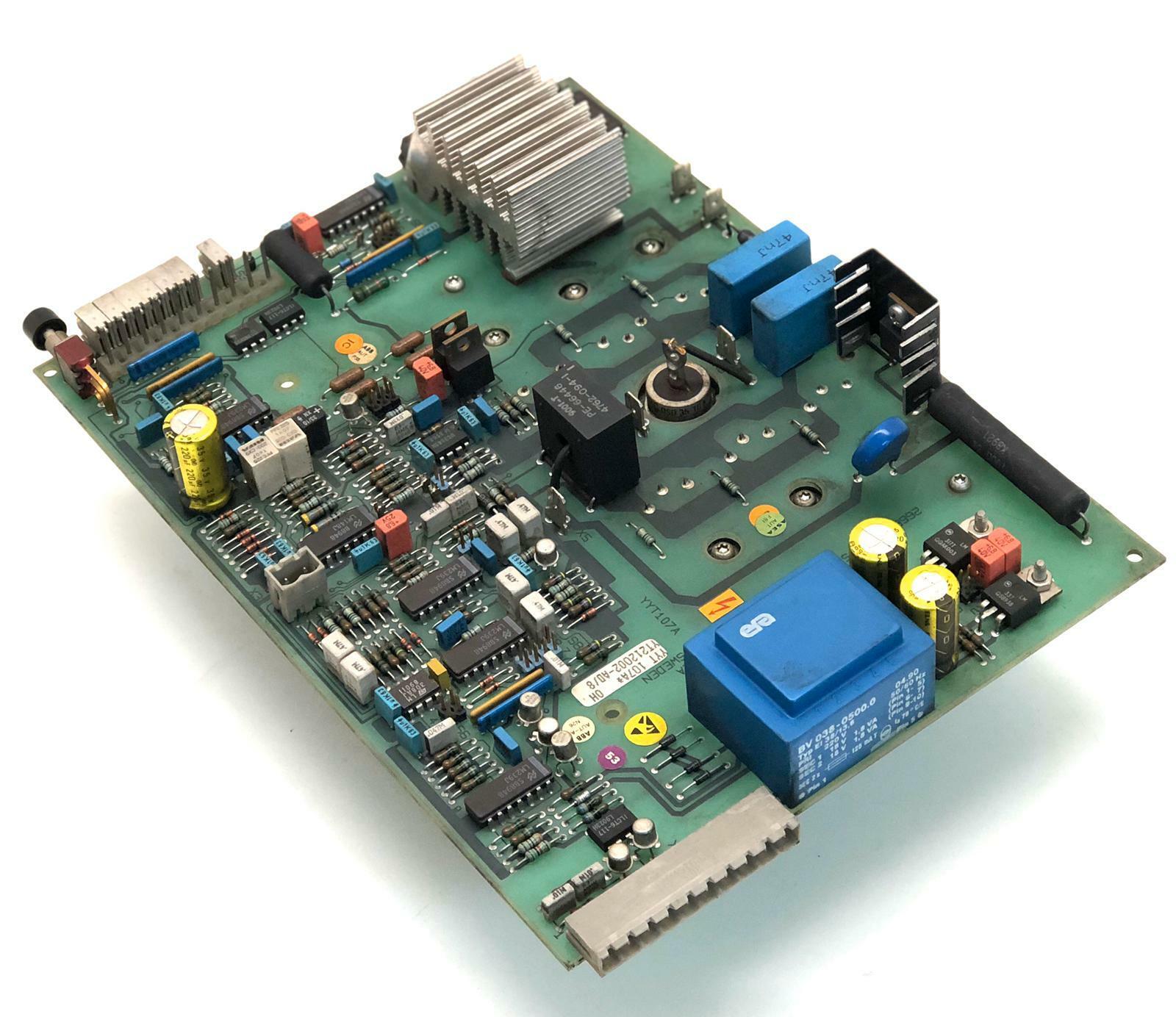

ABB YYT107A YT212002AD PLC module

ABB YYT107A YT212002AD PLC module

Product Overview

The ABB YYT107A YT212002AD PLC module is a core equipment designed specifically for industrial automation control systems, responsible for key tasks such as data processing, logic control, and equipment coordination in automated production processes. It can receive signals from various sensors, perform internal logic operations and program processing, output control instructions to drive actuators, thereby achieving automation control of industrial equipment, ensuring efficient, stable, and precise operation of the production process. It is widely applicable to various industrial scenarios, from simple single machine control to complex production line integration, and can play an important role.

Core functions

(1) Logic control function

Supports multiple programming languages, such as Ladder Diagram, Structured Text, Function Block Diagram, etc. Users can choose the appropriate language to write control programs according to their own needs and programming habits. The module is capable of performing basic logical operations (AND, OR, NOT, etc.), arithmetic operations, as well as complex sequential control and conditional judgment, to achieve logical control of various equipment in the industrial production process, ensuring that the production process runs in the predetermined order and conditions.

(2) Data processing and computation

Capable of powerful data processing and computation, capable of filtering, converting, and calculating collected digital and analog data. For example, linearizing analog data, converting engineering quantities, counting and timing digital data, providing accurate data support for control decisions, and achieving precise control of industrial process parameters.

(3) Communication and networking functions

Through rich communication interfaces and supported multiple communication protocols, it can communicate with upper computer monitoring systems, other PLC modules, touch screens, sensors and other devices. Realize real-time uploading and downloading of data, facilitate remote monitoring and management of industrial production processes by operators, and collaborate with other devices to build a distributed industrial automation control system, improving the intelligence and integration level of the system.

(4) Fault diagnosis and alarm

Built in comprehensive fault diagnosis system, capable of real-time monitoring of the operating status of internal circuits, I/O channels, communication connections, and other parts of the module. Once a fault is detected, such as abnormal input signals, communication interruptions, module overheating, etc., an alarm mechanism is immediately triggered. Fault information is fed back through LED indicator lights flashing, communication interface output fault codes, etc., which facilitates maintenance personnel to quickly locate and troubleshoot faults, ensuring the continuity of industrial production.

Working principle

After the ABB YYT107A YT212002AD PLC module is connected to the industrial automation control system, it first collects digital and analog signals from on-site sensors through the input interface. Digital signals are directly subjected to level conversion and isolation processing, while analog signals are converted into digital signals through A/D converters, and then these signals are transmitted to the central processing unit (CPU) inside the module.

The CPU performs logical operations and data processing on input signals based on control programs pre written by the user and stored in memory, generating corresponding control instructions. After processing, these control instructions are transmitted to actuators such as relays, solenoid valves, motor drivers, etc. through output interfaces to control the operating status of equipment and achieve regulation of industrial production processes.

Throughout the entire operation, the communication module is responsible for data exchange with external devices. On the one hand, the collected data and module operation status information are packaged according to the selected communication protocol and uploaded to the upper computer monitoring system or other network devices through the communication interface; On the other hand, it receives control instructions and parameter adjustment information from the upper computer or other devices, and transmits them to the CPU for processing. At the same time, the fault diagnosis module continuously monitors the operating status of each part of the module. Once an abnormality is detected, it immediately triggers an alarm and corresponding fault handling mechanisms.

Key advantages

(1) High reliability and stability

By using high-quality electronic components and advanced manufacturing processes, and undergoing strict quality inspection and aging testing, the module is ensured to be stable and reliable during long-term operation. Electrical isolation design and a comprehensive fault diagnosis mechanism enable it to effectively resist complex electromagnetic interference and environmental factors in industrial sites, reduce failure rates, minimize downtime, and ensure the continuity of industrial production.

(2) Powerful flexibility and scalability

Rich I/O point configuration and support for multiple programming languages enable users to flexibly customize control functions according to different industrial control needs. The modular design concept facilitates system expansion, allowing for easy increase in I/O points or expansion of other functions by adding expansion modules, meeting the needs of industrial production scale expansion and process upgrades.

(3) Efficient and user-friendly

The friendly programming interface and intuitive operation method lower the threshold for use, allowing even beginners to quickly get started. At the same time, comprehensive documentation and technical support facilitate users in program development, debugging, and maintenance, improving work efficiency.

(4) Wide compatibility

Supporting multiple industrial communication protocols and interfaces, it can seamlessly integrate with different brands and types of industrial automation equipment, facilitating the construction of diverse industrial automation control systems and meeting the application needs of different industries.

Precautions

(1) Installation environment requirements

When installing, a dry, well ventilated, and suitable temperature environment should be selected to avoid installation in places with high temperature, humidity, corrosive gases, or strong electromagnetic interference. If it is impossible to avoid harsh environments, effective protective measures should be taken, such as installing heat dissipation devices, electromagnetic shielding equipment, etc., to ensure the normal operation of the module.

(2) Wiring standard operation

Strictly follow the wiring diagram in the product manual to connect the power and signal lines, ensuring correct wiring and accurate polarity. Different types of signals (such as analog, digital, and power lines) should be wired separately to avoid signal interference. After the wiring is completed, carefully check whether the wiring terminals are secure to prevent loose connections that may cause poor contact or short circuits.

(3) Programming and Maintenance

Before programming and parameter setting, it is necessary to fully understand the industrial control requirements and the functional characteristics of the module, to ensure that the control program logic written is correct and the parameter settings are reasonable. Regularly maintain the module, including cleaning surface dust, checking electrical connections, backing up program data, etc., to ensure that the module is always in good operating condition.

Application scenarios

(1) Manufacturing automation production line

In automated production lines in industries such as automobile manufacturing and electronic equipment manufacturing, it is used to control the movement of robotic arms, the operation of conveyor belts, and the start stop of equipment, achieving automation and intelligence in the production process. By precise logical control and data processing, the processing accuracy and production efficiency of the product are ensured, and labor costs are reduced.

(2) Power system monitoring and control

In power plants, substations and other electrical facilities, it is used to monitor and control the operating status of electrical equipment, such as the speed, voltage, current of generators, and the opening and closing operation of circuit breakers. Realize automated monitoring and protection of the power system, and improve the reliability and stability of power supply.

(3) Automation of chemical production processes

In chemical production, precise control of key process parameters such as temperature, pressure, and flow rate of reaction vessels is necessary to ensure that chemical reactions occur under safe and stable conditions. At the same time, controlling the material conveying, mixing, separation and other links in the chemical production process can improve production efficiency, reduce production costs and safety risks.

(4) Intelligent Buildings and Building Automation

In intelligent building systems, it is used to control equipment such as elevator operation, lighting systems, air conditioning systems, security systems, etc. Realize automated management and energy-saving control of building equipment, providing users with a comfortable, convenient, and safe environment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands