ABB contactors and overload relays

Contactor:

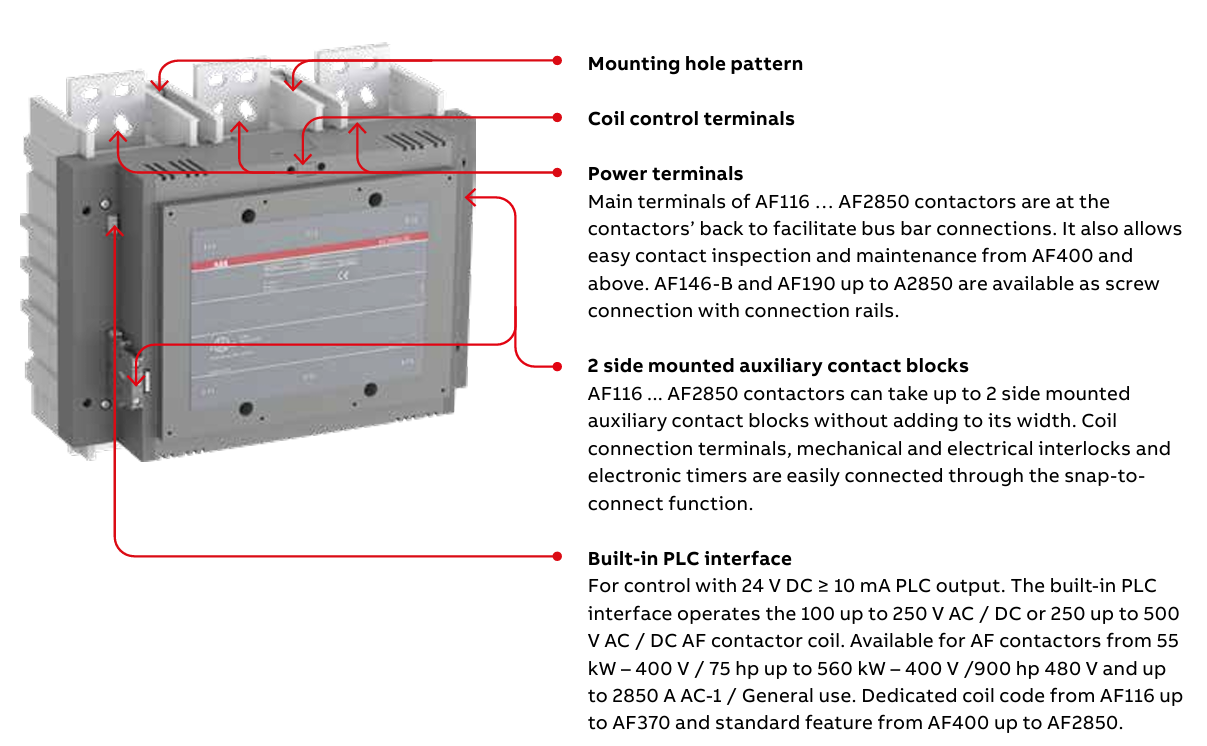

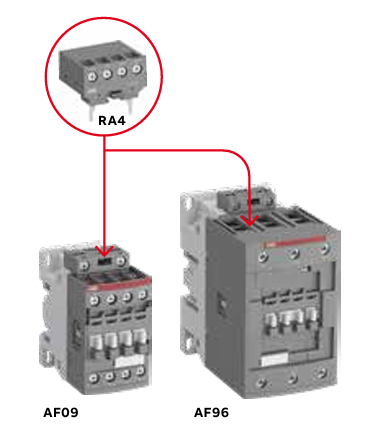

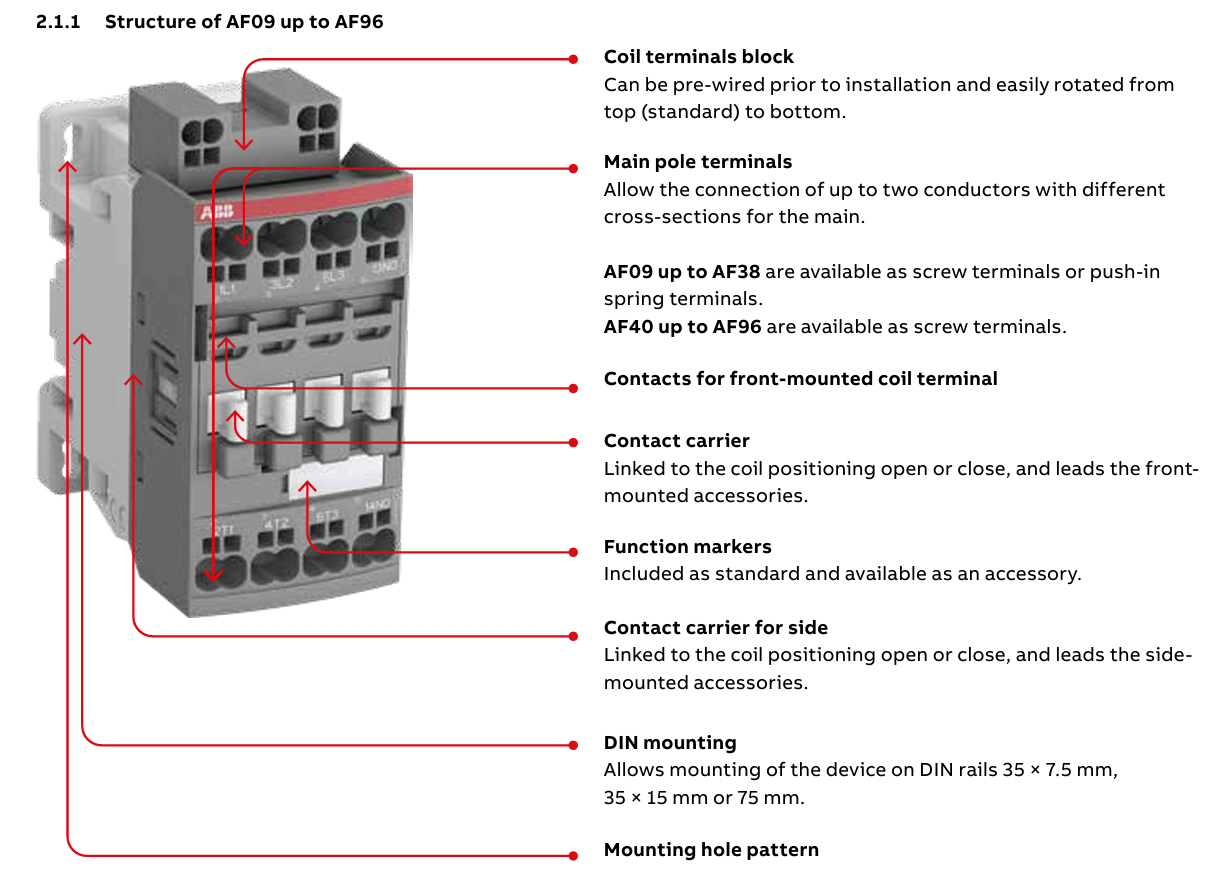

AX series: suitable for low-voltage distribution and motor control, with a current range of 6A-1000A, supporting AC/DC coils, featuring compact design and high mechanical life (≥ 10 million cycles).

AF series: designed for frequent operation scenarios such as elevators and cranes, with a current range of 9A-400A and a mechanical lifespan of up to 30 million cycles.

A-series: Classic series, covering 12A-630A, supports multiple coil voltages, and is compatible with global standards.

Overload relay:

TA series: Thermal overload relay, used in conjunction with contactors, with a current range of 0.1A-630A, providing manual/automatic reset function.

TF series: Electronic overload relay with precise protection (overload, phase loss, locked rotor, etc.), supporting communication functions (such as Modbus), current range of 0.1A-800A.

Combination product: Pre assembled units for contactors and overload relays (such as AX+TA, AF+TF), simplifying selection and installation.

ABB contactors and overload relays

Product Series Overview

The document covers multiple contactor and overload relay series under ABB, with core products including:

Contactor:

AX series: suitable for low-voltage distribution and motor control, with a current range of 6A-1000A, supporting AC/DC coils, featuring compact design and high mechanical life (≥ 10 million cycles).

AF series: designed for frequent operation scenarios such as elevators and cranes, with a current range of 9A-400A and a mechanical lifespan of up to 30 million cycles.

A-series: Classic series, covering 12A-630A, supports multiple coil voltages, and is compatible with global standards.

Overload relay:

TA series: Thermal overload relay, used in conjunction with contactors, with a current range of 0.1A-630A, providing manual/automatic reset function.

TF series: Electronic overload relay with precise protection (overload, phase loss, locked rotor, etc.), supporting communication functions (such as Modbus), current range of 0.1A-800A.

Combination product: Pre assembled units for contactors and overload relays (such as AX+TA, AF+TF), simplifying selection and installation.

Core technical parameters and performance

Key indicators of parameter categories

Electrical performance - rated voltage: AC below 690V, DC below 250V (some models support higher voltages).

-Breaking capacity: It can reach 10 times the rated current under AC-3 load (such as AX18 with a breaking capacity of 100A at 400V).

-Coil power consumption: AC coil ≤ 15VA, DC coil ≤ 10W, energy-saving coil power consumption reduced by more than 50%.

Mechanical performance - Operating frequency: up to 1200 times/hour (AX series), AF series supports higher frequencies (such as 3600 times/hour).

-Protection level: The contactor body is IP20, and after installing a casing, it can reach IP65.

-Installation method: DIN rail installation (35mm) or screw fixation, supporting vertical/horizontal installation.

Protection Function - Overload Relay: The TA series achieves overload protection through bimetallic strips, while the TF series has an electronic trip curve (Class 10/20/30) and customizable protection parameters.

-Contactor: equipped with an arc extinguishing cover to reduce damage to the contacts caused by the arc, and supports reversible control (through mechanical interlocking).

Environmental adaptability - Operating temperature: -25 ° C to+70 ° C (some models -40 ° C to+70 ° C).

-Vibration resistance: 10-55Hz, amplitude 0.75mm; Impact resistance: 30g (11ms).

Selection and Application Guide

Selection criteria: Select the model based on the load type (motor, lighting, electric heating, etc.), rated current, operating frequency, protection requirements (overload, short circuit, etc.), and environmental conditions (temperature, humidity). The document provides a detailed selection table, including the current matching relationship under different load types (such as AC-1 resistive load, AC-3 motor load).

Typical application scenarios:

Industrial motor control (pumps, fans, conveyors).

Low voltage distribution system (distribution box, switchgear).

Building automation (air conditioning, elevators).

Renewable energy sources (photovoltaic inverters, wind power converters).

Installation and maintenance

Installation points:

Wiring: The main circuit uses copper or aluminum cables (with copper aluminum transition terminals), and the cross-sectional area of the control circuit wires is 0.5-2.5mm ², with a tightening torque of 0.5-2.5Nm (depending on the terminal specifications).

Spacing requirement: Contactors of different current levels must maintain a certain electrical clearance (such as 100A or above ≥ 15mm) to ensure heat dissipation and insulation.

Maintenance suggestion: Regularly check contact wear (replace when thickness ≤ 1mm), clean the arc extinguishing cover, test the accuracy of overload relay action, and avoid long-term operation in dusty and corrosive environments.

Certification and Standards

Compliant with international standards: IEC 60947-1/4 (contactors), IEC 60947-5-1 (overload relays).

Certification coverage: CE, UL, CSA, CCC, GL (Classification Society), etc., applicable to the global market.

Additional Information

Provide technical charts such as product size diagrams, wiring diagrams, trip curves (overload relays), and lifespan curves to assist in installation and debugging.

Contains environmental information: The product materials comply with the RoHS directive, and the proportion of recyclable parts is ≥ 90%.

Emphasize safety reminder: Installation should be operated by professional electricians, and maintenance should be carried out after power failure to avoid electric shock or mechanical injury.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands