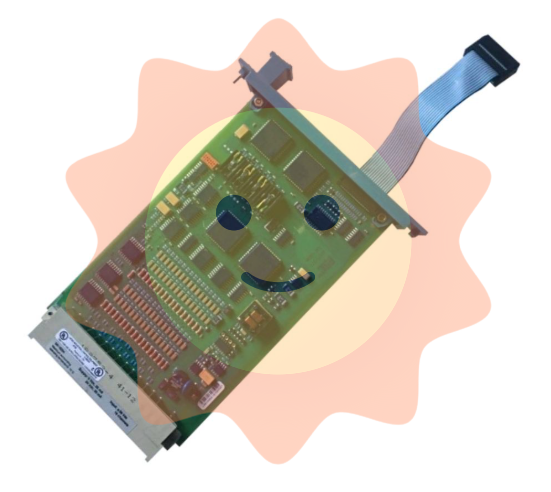

ABB 0338434M-REF Refurbished DLM 02, Link module, as of V3

ABB 0338434M-REF Refurbished DLM 02, Link module, as of V3

Product Features:

Efficient and Reliable: a high-performance component designed to integrate seamlessly into industrial automation systems to improve efficiency and reliability in a variety of manufacturing environments.

Adaptable: Its rugged design ensures reliable operation in a wide range of environmental conditions for applications ranging from manufacturing floors to power plants.

Easy to Integrate: Featuring a compact and durable construction, it integrates seamlessly into existing PLC systems, enhancing their functionality with high-speed data transfer and enhanced connectivity options.

User-friendly: Designed with user-friendliness in mind, it features an intuitive setup procedure and comprehensive documentation to ensure quick and easy installation and maintenance.

Supports multiple protocols: the module supports a wide range of communication protocols for smooth interoperability with a wide range of equipment and systems in a plant or industrial environment, as well as advanced diagnostic features that enable proactive maintenance planning and minimise downtime.

Technical Parameters:

Weight: approx. 1.68kg.

Dimensions: 175.26mm x 35.56mm x 297.18mm.

Operating temperature range: -25°C to + 55°C.

Certification: CE, UL, CSA and other certifications.

Place of origin: Germany, Sweden and other countries of origin.

Refurbishment process for link modules

Module Receiving and Evaluation: After receiving the DLM 02 link module to be refurbished, the staff will carry out a preliminary inspection, record the module's appearance condition, labelling information, damage, etc., evaluate the overall condition of the module, and determine the content and difficulty of the refurbishment work to be carried out.

Comprehensive disassembly: The module will be disassembled to separate the components, such as circuit boards, chips, capacitors, resistors, interfaces, etc., in order to carry out an in-depth inspection and processing of each part.

Thorough cleaning: Use professional cleaning equipment and reagents to clean each component after disassembly, removing dust, oil, stains and other impurities on the surface to ensure that the surface of the component is clean and tidy for subsequent testing and repair work, and also to help improve the module's thermal performance and electrical performance.

Component testing and analysis: Using professional testing equipment and technology, each component is tested in detail, including electrical performance tests, functional tests, aging tests, etc., to analyse whether there is any damage, performance degradation, potential failures, etc., and to determine the components that need to be replaced.

Fault Repair and Component Replacement: For detected faulty components, such as damaged circuit boards, short-circuited capacitors, failed chips, etc., repair or directly replace them with original spare parts or certified high-quality alternatives. Ensure that the replaced components are compatible with the original module to ensure the performance and stability of the module.

Re-assembly: After testing, repairing and replacing the components, reassemble each component into a complete DLM 02 link module in accordance with strict assembly techniques and procedures to ensure that no parts are missing or incorrectly installed, and that all interfaces and connections are firm and reliable.

Comprehensive testing: Conduct comprehensive function, performance and stability tests on the refurbished module, simulating various working scenarios and conditions to check whether the module can work normally and whether the performance indexes meet the standards specified by the original manufacturer, such as communication function, data transmission rate, signal stability, and so on.

Appearance Repair and Logo Update: Repair and tidy up the appearance of the module to bring it back to a nearly new state, update the logo, label and other information on the module, including version number, production date, refurbishment date, etc., to ensure that the information is accurate and clear.

Packaging and Shipping: Pack the refurbished modules that have been tested and qualified, using suitable packaging materials, such as anti-static bags, foam boxes, etc., to prevent damage during transport, and then send them back to the customer.

SAFETY INSTRUCTIONS

1. All servicing should be performed by qualified service personnel.

2. All unused wires must be insulated to prevent shorting.

3. Do not use outdoors.

4. Do not let power supply cords touch hot surfaces.

5. Do not mount near gas or electric heaters.

6. Use caution when handling batteries. Battery acid can cause burns to the skin and eyes. If acid is spilled on the skin or eyes, flush affected area with fresh water and contact a physician immediately.

7. Avoid possible shorting.

8. Equipment should be mounted in locations and at heights where it will not

readily be subjected to tampering by unauthorized personnel.

9. The use of accessory equipment not recommended by the manufacturer may

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands