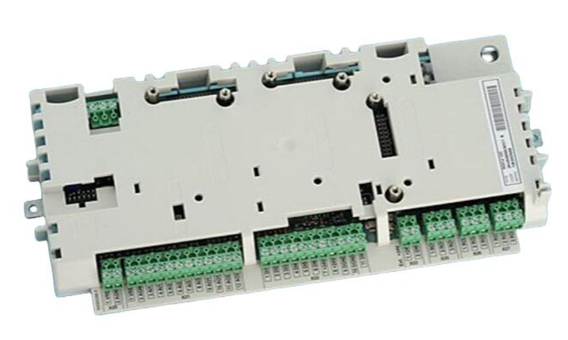

ABB RMIO-12C control unit

Belonging to the RMIO series, brand ABB, model RMIO-12C, weighing 0.6kg, module size 150 × 100 × 80mm, certified by CE, UL, CSA, etc., in compliance with industry quality standards.

ABB RMIO-12C control unit

ABB RMIO-12C is a widely used control unit in the field of industrial automation, with many advantages such as high performance and high reliability.

Basic information

Belonging to the RMIO series, brand ABB, model RMIO-12C, weighing 0.6kg, module size 150 × 100 × 80mm, certified by CE, UL, CSA, etc., in compliance with industry quality standards.

Performance parameters

The working voltage is 120V AC or 24V DC (some data shows 220V), the working frequency is 50kHz, and the output frequency is also 50kHz. It can provide precise control for equipment that requires high response speed and control accuracy, such as high-speed motors. Supports communication protocols such as Modbus RTU/TCP for easy communication with other devices that support this protocol, enabling system integration and remote monitoring. There are 16 input channels and 16 output channels, which can connect various sensors and actuators to meet the control needs of different industrial scenarios.

Functional features

Adopting advanced microprocessor technology, built-in multiple control algorithms, customizable programming, able to design control strategies according to different industrial needs, such as controlling the operation process and parameters of equipment in industrial automation production lines. Supporting remote control and monitoring, with the help of communication interfaces, operators can remotely operate and monitor the status of equipment, improving the convenience and efficiency of production management. Equipped with comprehensive safety protection functions, it can monitor the operating status of equipment, and take timely protective measures in case of abnormalities such as overload and short circuit to ensure the safety of equipment and personnel. Equipped with a software library that includes rich pre-defined and user-defined control elements, it is easy to design various control strategies, covering continuous control, timing control, etc., to adapt to complex industrial control requirements.

Application areas

Widely used in industrial automation production lines, controlling the operation of various equipment, improving production efficiency and product quality; In robot control systems, precise control of robots is achieved to enable them to complete complex tasks; In industries such as manufacturing, energy, and process control, control and monitor equipment such as motors, generators, and transformers to ensure stable system operation.

Related configuration

As part of the control unit in ABB ACS800 frequency converter, it works in conjunction with rectifier unit, energy storage unit, inverter unit, etc. to achieve drive control of the motor and stable operation of the entire system. It can seamlessly integrate with various ABB products, build comprehensive automation solutions, and enhance the overall performance and compatibility of the system.

Connector type and parameters

There are various types of connectors, such as X20 (constant voltage output) with 2-pole detachable screw terminal blocks, etc. Different connectors are suitable for different wire specifications, torques, spacing, etc.

Constant voltage output (X20, X21:1): Voltage of+10 VDC, 0, -10 VDC ± 0.5% (full-scale range) (at 25 ° C), maximum temperature coefficient of ± 100 ppm/° C, maximum load of 10mA, suitable for potentiometers 1 to 10 kohm.

Analog inputs (X21): Two programmable differential current inputs and one programmable differential voltage input, with analog inputs grouped together for galvanic isolation, etc.

Analog output (X21): Two programmable current outputs with a resolution of 0.1% (10 bits), etc.

Digital input (X22): Six programmable digital inputs and one startup interlock input, internal digital input power supply (+24 VDC) with short-circuit protection, etc.

24 VDC power output (X23): Voltage 24 VDC ± 10%, with short-circuit protection, maximum output current 250 mA (when no optional module is inserted).

Relay outputs (X25, X26, X27): Three programmable relay outputs with corresponding specifications for switch capacity.

Slot 1 (X31), Slot 2 (X32): Used for connecting related expansion modules, etc.

DDCS (X33): Used to connect RDCO-0x (C) DDCS communication module.

24 VDC power input (X34): Voltage 24 VDC ± 10%, typical current consumption (without option module) 250 mA, maximum current consumption 1200 mA (with option module inserted), etc.

Control panel connection (X39): used to connect the CDP-312R control panel.

PPCS link (V57, V68): Fiber optic connection to inverter (or IGBT power supply) module, optical component type 10 MBd, protocol ABB PPCS.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands