ABB UNITROL® 6000 Excitation systems

ABB UNITROL ® 6000 Excitation systems

System Overview

ABB UNITROL ® 6000 excitation system is a benchmark product in the field of power generation, which has set the industry standard in terms of progressiveness technology and operational availability. As a core component of many power generation units, it can help power plant owners and operators achieve reliable operation, stable performance, and fast transient response of assets, fully meeting the requirements of the power grid for power generation equipment.

The system has a wide range of applications, covering various power generation and industrial scenarios:

Generator field: Suitable for generators in steam, gas, nuclear, and hydroelectric power plants, including nuclear emergency diesel generators.

In the field of electric motors, they can be used in places such as steel mills, pulp and paper mills, chemical plants, natural gas production plants, refineries, etc.

System version and features

UNITROL ® The 6000 excitation system is divided into two versions, Medium and X-power, each with its own characteristics for different scale application scenarios.

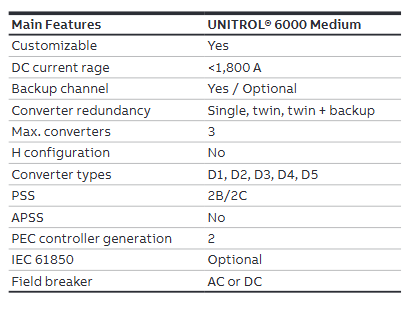

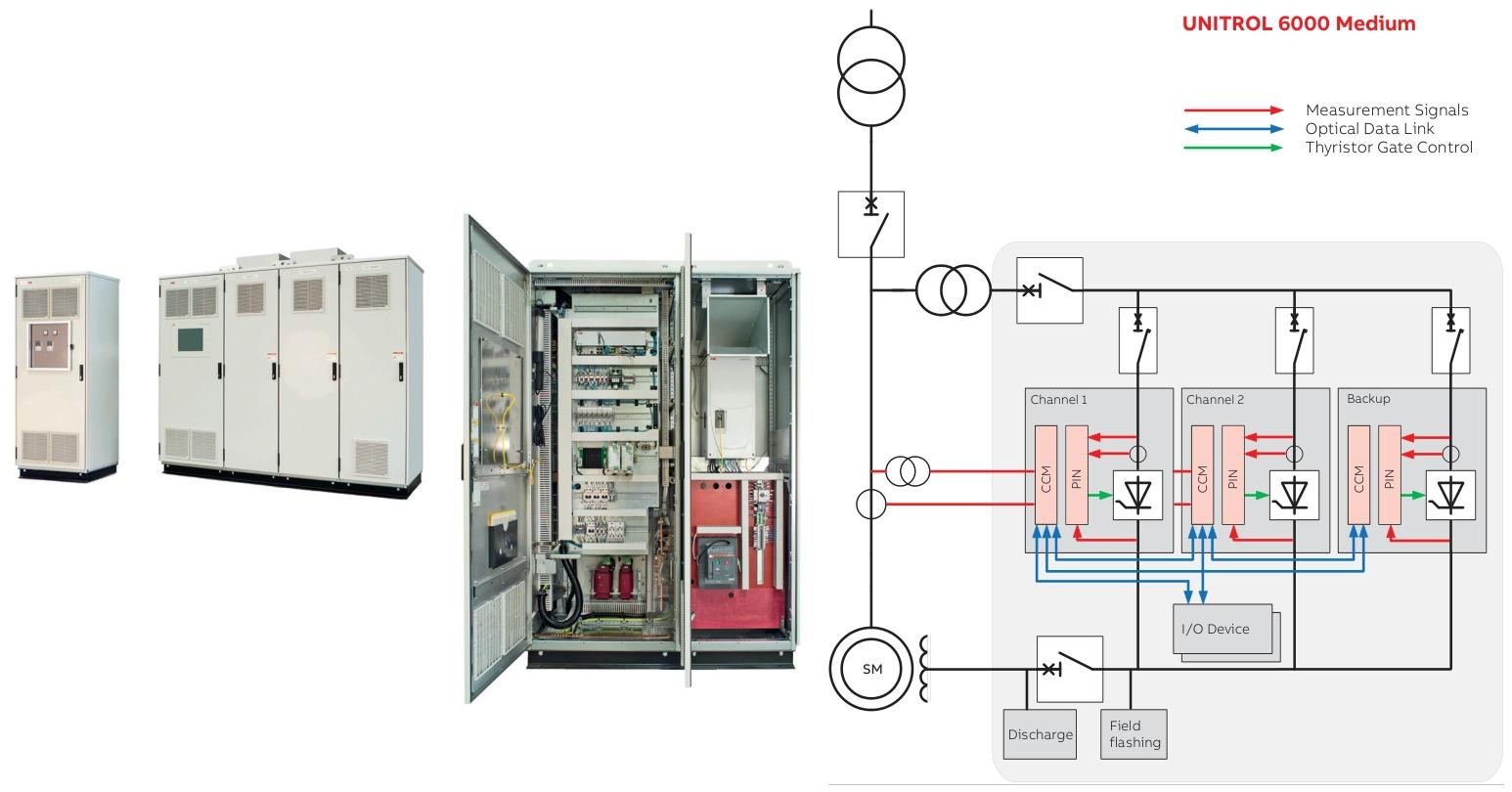

(1) UNITOL ® 6000 Medium

This is a customizable solution designed specifically for small and medium-sized static excitation systems, setting a benchmark for flexibility, reliability, and connectivity in brushless and critical steam generator sets.

Configuration and selection:

Supports single/dual channel configuration, with additional backup channels available upon request.

Provide a variety of thyristor bridge module options to meet various on-site data and availability requirements.

Typical applications:

Hydroelectric power plants, pumped storage power plants, and combined cycle power plants.

A key steam power plant using brushless excitation, excitation current of 200A, and power supply frequency of 400Hz.

Engineering solution: It has functions such as online power conversion and electric braking.

Main parameters:

DC current range:<1800A.

Converter redundancy: single channel, dual channel, dual channel+backup.

Maximum number of converters: 3.

Converter types: D1, D2, D3, D4, D5.

Power System Stabilizer (PSS): 2B/2C.

Adaptive Power System Stabilizer (APSS): None.

PEC controller version: 2nd generation.

IEC 61850 standard: optional.

Excitation circuit breaker: AC or DC.

(2) UNITOL ® 6000 X-power

This version is designed specifically for large power generation units, setting new benchmarks in flexibility, reliability, and connectivity.

Configuration and selection:

Supports single/dual channel control configuration and can be equipped with backup controllers according to requirements.

Provide a variety of thyristor bridge module options to meet various on-site data and availability requirements.

Typical applications:

Nuclear power plants with excitation current>10000A.

An underground hydroelectric power plant with an excitation current of 4500A and equipped with a redundant air-water heat exchange system.

A gas turbine power plant (MEGATROL package) equipped with a 15MW static frequency converter for turbine start-up and excitation current of 6000A.

The power part is located in a coal-fired power plant with an IP54 protection level container, automatic voltage regulator cabinet spacing>150m, and excitation current of 3500A.

A hydroelectric power plant equipped with two DC excitation circuit breakers (one for DC backup excitation) and an excitation current of 4000A.

Main parameters:

DC current range: 1800A<X<12000A.

Converter redundancy: single channel, dual channel, n-x redundancy.

Maximum number of converters: 8.

Equipped with H-shaped configuration.

Converter types: D5, UNL13300, UNL14300.

Power System Stabilizer (PSS): 2B/2C/4B.

Adaptive Power System Stabilizer (APSS): Yes.

PEC controller version: 3rd generation.

IEC 61850 standard: standard configuration.

Excitation circuit breaker: AC (4000A) or DC.

Control function

UNITROL ® The control function of the 6000 excitation system is comprehensive and powerful, covering multiple aspects such as closed-loop control, protection monitoring, data recording, and power system stability, ensuring the safe and stable operation of the generator.

(1) Closed-loop control

In automatic mode, equipped with a voltage regulator with PID filter.

In manual mode, equipped with an excitation current regulator with PI filter.

Capable of compensating for reactive and/or active current sag.

Multiple limiter circuits are installed to ensure the safe operation of the generator, including maximum and minimum excitation current limits, maximum stator current limit depending on the temperature of the motor cooling medium, P/Q under excitation limit, volt/hertz limit, etc.

The manual restriction function can keep the generator within a safe range even in manual control mode.

Support power factor/reactive load control.

(2) Protection and monitoring functions

The monitoring and protection functions can be freely configured at three action levels: only issuing alarm signals, switching to redundant circuits, and instantaneous excitation tripping to protect assets.

The main functions include overcurrent protection (instantaneous/inverse time limit), volt/hertz protection, demagnetization protection, rotor temperature monitoring, thyristor conduction monitoring, actual value monitoring, etc.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands