ABB UNITROL® 6000 Excitation systems

(3) Data and event recording

The internal event recorder can process and store up to 2000 events, each with a real-time timestamp.

The data logger includes a pre configured section that can record a large number of measurement values and internal signals. It will automatically trigger when a fault occurs, facilitating efficient troubleshooting and continuous improvement to maximize availability.

It also provides a freely configurable high-speed recorder for compliance testing or network event analysis.

(4) System time synchronization

The system clock of all controllers can be synchronized with the time source through the Simple Network Time Protocol (SNTP), with an accuracy of up to 1ms, making it easy to efficiently troubleshoot and keeping the excitation event log consistent with other logs in the power plant, shortening the time for the unit to reconnect to the grid.

(5) Power System Stabilizer (PSS)

The PSS function suppresses power oscillations and improves the stability of the generator and transmission system through excitation. UNITROL ® 6000 optional PSS types include:

Compliant with IEEE Standard 421.5-2016 PSS 2A/2B/2C.

Compliant with IEEE Standard 421.5-2016 PSS 4B/4C.

The Adaptive PSS (APSS) developed by ABB Switzerland can optimize PSS settings based on current network conditions, maximize availability, and avoid tripping due to insufficient damping in weak power grids.

Hardware and software

(1) Hardware components

The system is built on the AC 800PEC high-performance processor family, which is an extension of the ABB 800xA control platform developed specifically to meet the fast control requirements of power electronics.

Control section:

The AC 800PEC control system has extremely high processing speed, providing fast analog and digital process I/O with a typical cycle time of 400 µ s.

Implement fast closed-loop control and conventional process logic in a single controller.

The typical cycle time for low-speed I/O is 10ms.

Ultra fast programmable logic for converter pulse control and optical communication, with a cycle time as low as 25ns.

Power converter:

The power converter for each channel is selected based on the system requirements for maximum excitation current and voltage.

Up to three redundant channels can be equipped, and online maintenance options (optional) are provided to meet strict availability requirements.

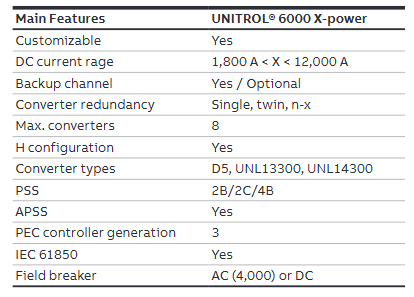

ABB has developed a series of thyristor power converters specifically designed for direct (static) and indirect excitation systems, such as D1 to D5, UNL13300, and UNL14300.

The main features of D1 to D5 power converters are: single-phase or three-phase AC power supply voltage up to 1080V; rated power supply frequency 50 to 480Hz (16 ⅔ Hz can be provided according to requirements); The cooling fan has low noise, ≤ 70dB (A); Compact design, fully integrated converter and control, with integrated service panel.

The main features of UNL14300 power converter are: AC power supply voltage up to 1500V; insulation test voltage up to 7.5kV; low cooling fan noise, ≤ 70dB (A); Capable of active current balance control; Optional redundant fans (replaceable during operation) and "pull-out" design (convenient for safe online maintenance and functional testing).

(2) Software functions

The software includes all the necessary regulation, protection, and monitoring functions to ensure the safe operation of the generator as standard features. To meet the specific needs of any application, the software can be easily configured and adjusted.

Simulators and compliance with power grid standards

(1) SMTS-RT 6000 Simulator

SMTS-RT 6000 is a "hardware in the loop" simulator that can simulate generators/motors, their turbines/loads, and the power grid. The simulator is connected to the excitation system for closed-loop testing to analyze its static and transient behavior.

Function: Reduce motor testing time, save costs, and serve as an ideal training tool for maintenance and operation personnel.

Advantage: By using simulators and UNITOL ® Pre adjusting the control parameter set of the 6000 control device can further shorten the debugging time.

(2) Compliance with power grid regulations

UNITROL ® The control function of 6000 can support any grid specification. The extensive testing capabilities and powerful data logger of the excitation control terminal (ECT) are used to test, adjust, and demonstrate the performance of control, stabilizer, and limiter functions.

Testing tool: The built-in white noise generator can quickly and accurately analyze the system frequency response, and perform compliance testing in the least amount of time.

Data storage: Data records are stored in ECT's dedicated memory, which can be easily copied and integrated into electronic documents.

Joint testing: When used in conjunction with SMTS-RT 6000, it can simulate the most critical power plant or grid conditions that are typically not safe to test in actual systems.

Communication function

UNITROL ® The communication function of the 6000 excitation system ensures convenient human-machine interaction and efficient integration with the power plant control system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands