ABB UNITROL® 6000 Excitation systems

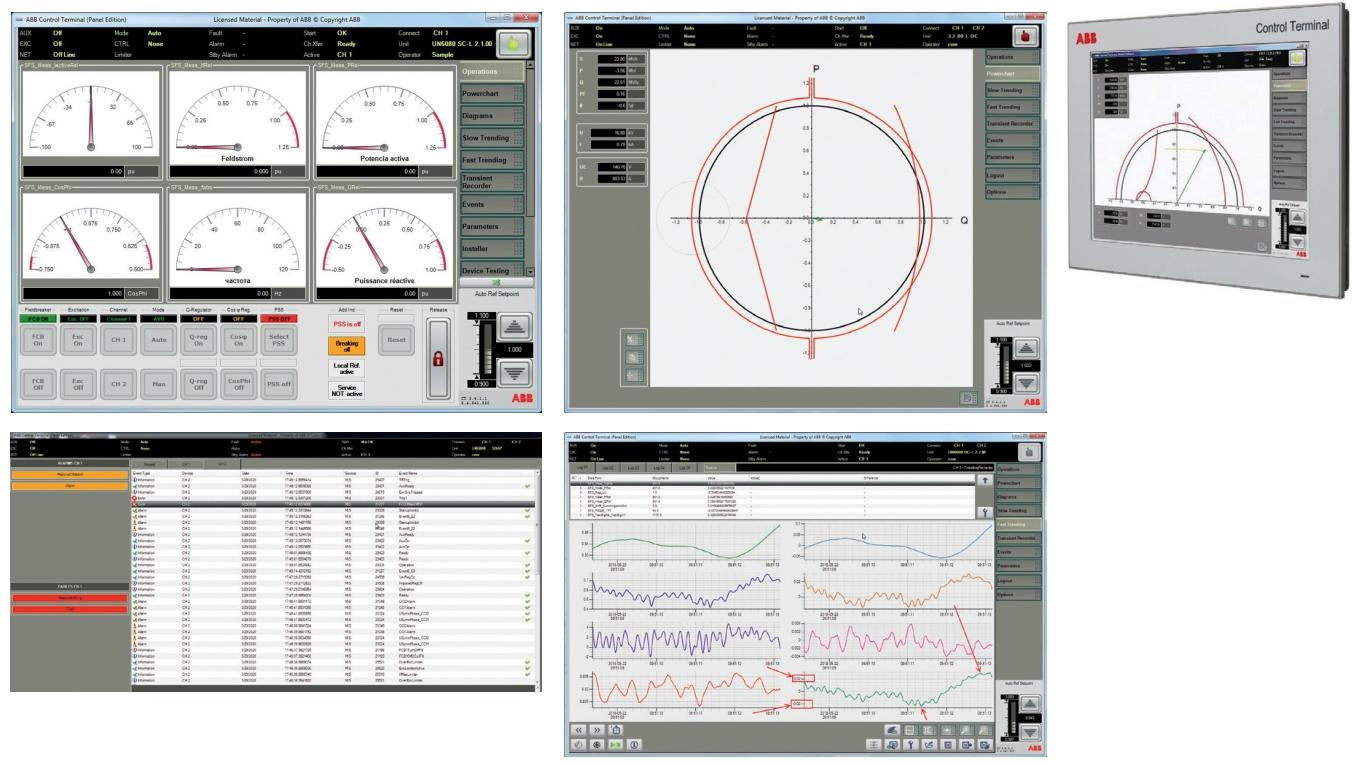

(1) Excitation Control Terminal (ECT)

ECT is a user-friendly human-machine interface that supports system operation, monitoring, and maintenance. It is a high-performance industrial grade touchscreen PC that operates independently of the system controller.

Function: Can record events and system data for a long time.

Display: LCD touch screens provide operators with multiple optional screens to display the actual status of the system in both graphical and numerical form.

Compatibility: Running on Windows 10 system, it can also be installed on any PC for debugging.

(2) Integration with power plant control system

Supports Ethernet and fieldbus protocols (Modbus RTU, Modbus TCP, Profibus DP-V0) as well as IEC 61850 as the primary choice for communication with power plant control systems. The emergency control signal can be directly hard wired to the control board.

(3) Remote service

UNITROL ® 6000 supports remote access through ABB RAP platform or customer internal tools. In this way, the local maintenance team can receive necessary support from ABB service experts, which helps to reduce maintenance and service related costs.

Service and Support

ABB for UNITOL ® The 6000 excitation system provides comprehensive services and support, covering installation, commissioning, training, lifecycle management, and other aspects to ensure the reliable operation of the system throughout its entire lifecycle.

(1) Installation and debugging

ABB engineers possess professional competence, extensive experience, and multilingual abilities to ensure satisfactory installation and commissioning of the system.

(2) Training services

ABB University offers services for UNITOL ® The standard and customized training courses for the 6000 excitation system have two options: virtual and on-site training. For a detailed training plan, please visit www.abb.com/abbuniversity.

(3) Lifecycle Management

ABB's excitation system lifecycle management model helps customers extend and maximize the lifecycle of their assets at the lowest cost. Based on the lifecycle stages of the product, service experts will recommend necessary actions and proactively contact customers to inform them of all maintenance, service, and upgrade requirements.

Excitation care plan: comprehensively covering all maintenance needs of customers.

Example of lifecycle services: providing technical support for optimizing reliability, remote services, maintenance and repair, expansion, upgrading, and transformation.

Lifecycle Stage Services:

Active period: The product is available for purchase and provides a complete lifecycle service.

Classic period: The product can be used for power plant expansion, providing spare parts, maintenance, and repair services.

Limited term: As long as materials are available, spare parts, maintenance, and repair services are provided, but lifecycle services are limited.

Elimination period: Due to technical or cost reasons, ABB cannot guarantee the availability of lifecycle services, but will provide technical solutions for asset transformation or upgrading.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands