TOSHIBA Welker Bearing Linear Guides and Wedge Components

Linear Slides: Achieve smooth and precise linear reciprocating motion of equipment components, undertaking dual functions of guidance and load-bearing;

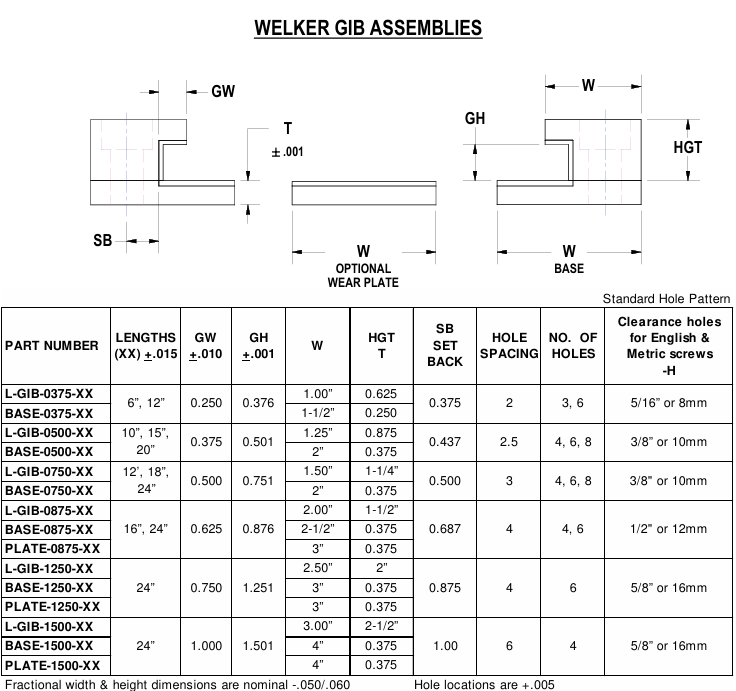

Gib Assemblies: Used in conjunction with linear guides to adjust guide clearance, compensate for wear, improve motion accuracy and stability, and some models can be used independently as guide components.

2. Key technical parameters

Material: Same linear guide rail, mainly made of 1045 high carbon steel (quenched HRC 55-60), optional stainless steel;

Slope accuracy: Slope angle tolerance ± 0.5 °, surface roughness Ra ≤ 1.6 μ m;

Adjustment range: The gap adjustment of the adjustable wedge block is 0.001-0.01 inches (0.025-0.254mm), meeting different precision compensation requirements;

Adaptive guide rail: It can be matched with Welker's full range of linear guides, and can also be customized according to the customer's existing guide rail size (a cross-sectional view of the guide rail is required).

Customized services and design support

1. Customized service scope

Welker Bearing provides comprehensive customized solutions, with core customization content including:

Customization of dimensions: rail length, cross-sectional dimensions, installation hole positions/quantities;

Material and surface treatment customization: stainless steel material (rust proof), special alloy (high temperature/corrosion resistance), customized surface coating (such as PTFE coating for friction reduction);

Function customization: Add position sensor interface (such as grating ruler installation slot), integrate dust cover (anti debris/dust), design special lubrication system (automatic lubrication);

Adaptability customization: Design non-standard wedge components or rail structures based on the installation space and load-bearing requirements of the customer's existing equipment rails.

2. Design support services

Technical consultation: Provide linear motion scheme evaluation to assist customers in selecting suitable product series;

Drawing support: Provide 2D (CAD)/3D (SolidWorks) model drawings for customers to integrate into equipment design;

Sample production: Customized products can provide sample testing (sample fee required, refundable after bulk order);

Installation guidance: Provide installation manuals and videos, and if necessary, dispatch engineers to provide on-site guidance for installation.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor