ABB NTAC-0x pulse encoder interface module

Attention: Emphasize following the manufacturer's operating instructions to avoid hazards such as electric shock.

ABB NTAC-0x pulse encoder interface module

Safety instructions

Warning types: including dangerous voltage warning, general warning, electrostatic discharge warning, reminding users to have professional electricians perform electrical installation and maintenance. Drivers and related equipment must be properly grounded. After power failure, wait for 5 minutes for the intermediate circuit capacitor to discharge, and use voltage indicating instruments to confirm the completion of discharge. At the same time, be aware of the risks that may arise from the automatic reset function of the driver.

Attention: Emphasize following the manufacturer's operating instructions to avoid hazards such as electric shock.

Overview

Scope of application: Applicable to NTAC-02 (revised version C and above), NDIO-02 (revised version A and above), NAIO-03 (revised version A and above), and includes reference information from earlier versions (NTAC-01, NDIO-01, NAIO-01/02).

Module function:

NTAC-02: Provides a digital pulse encoder interface for obtaining precise speed or position feedback of the motor shaft.

NDIO-02: Provides 2 digital inputs and 2 relay outputs.

NAIO-03: Provides 2 analog inputs and 2 analog outputs, with signal resolution (12 bits) superior to standard analog I/O.

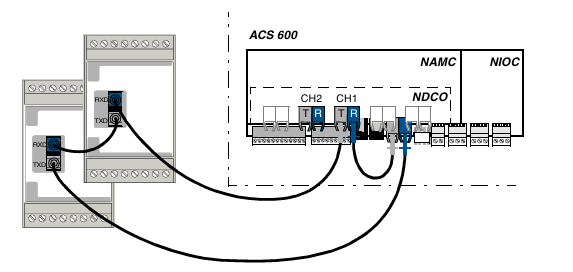

Communication link: Connected to the frequency converter through an optical DDCS protocol communication link, the module and NIOC standard I/O board usually form a circular connection on the CH1 channel of the NAMC board, which acts as the main station to cyclically poll other stations.

install

Module Node Number Setting: Different modules (NTAC, NDIO, NAIO) have their own node numbering rules set through DIP switches inside the module casing. The new settings will take effect when the module is powered on next time.

Mechanical installation: It can be installed inside or outside the drive. When installing outside, attention should be paid to wiring, space, environmental conditions, and grounding requirements. When installing inside, it should be operated by a professional electrician, following steps such as power-off, discharging, and removing the cover plate.

ACS 600 connection: Use fiber optic cables to connect to the NAMC/NDCO board of the driver, paying attention to the color coding of the connectors (blue for RXD, gray/black for TXD). Multiple modules are connected in a circular manner on the same channel, and the terminals connected to different modules vary depending on the application.

Detailed installation and configuration of each module

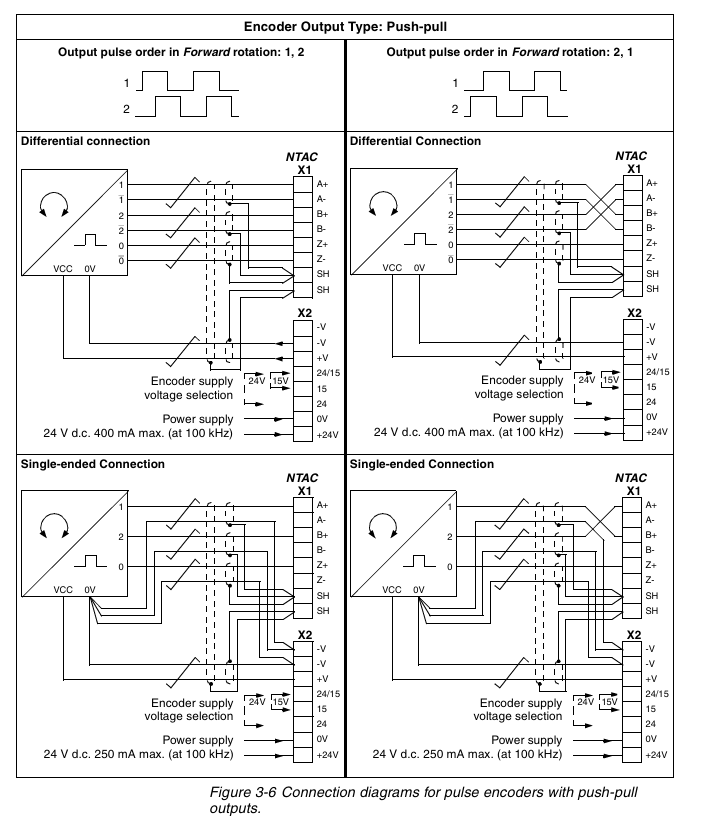

NTAC-02 pulse encoder interface module: introduces terminal identification, current consumption, wiring requirements (cable type, length, shielding grounding, etc.), encoder output type connection diagram (push-pull, collector open circuit, emitter open circuit), and programming method (set through driver parameters).

NDIO-02 digital I/O expansion module: including terminal identification, wiring recommendations, DI1 hardware filter suppression settings, and programming methods (activating communication through driver parameters).

NAIO-03 Analog I/O Expansion Module: Includes mode selection (unipolar/bipolar), input signal type selection (current/voltage), terminal identification, wiring requirements, programming methods (activates communication through driver parameters to ensure parameter settings correspond to module mode switches).

Appendix Information

Technical data: including detailed technical parameters such as I/O expansion links, enclosure of each module, installation, connectors, input and output.

Environmental conditions: lists the environmental requirements for temperature, humidity, vibration, impact, etc. of the module during operation, storage, and transportation.

Early version information: Introduces the differences, terminal identification, settings, and other information between NTAC-01, NDIO-01, NAIO-01/02 and their corresponding new versions.

Install and start ABB NTAC-0x module

Installation preparation

Confirm compatibility

The module needs to be used in conjunction with the ACS 600 series frequency converter, and the application version must be ≥ V5.0 (standard application) or ≥ V4.2 (system application).

Check the encoder type (push-pull, open collector or open emitter) and prepare matching connecting cables.

Safe power outage

Disconnect the main power supply of the frequency converter and wait for 5 minutes until the intermediate circuit capacitor discharges completely.

Use a voltage indicator to confirm that there is no residual voltage.

Physical installation steps

1. Node number setting

Open the module casing and set the node number (range: 1-31) through the DIP switch.

Rule:

The NTAC module number needs to be an even number (such as 2, 4, 6...).

Node numbers within the same channel cannot be duplicated.

After the setting is completed, it will take effect when powered on again.

2. Mechanical installation

Internal installation (recommended):

Remove the cover plate of the frequency converter and insert the module into the CH1 channel of the NAMC board or NDCO board.

Connect the RXD (blue interface) and TXD (gray/black interface) of the module using fiber optic cables to form a circular topology.

External installation:

Choose a dry and ventilated location to ensure that the ambient temperature is between -25 ° C and+55 ° C.

Fix the module with M4 screws and maintain a minimum spacing of 50mm.

3. Encoder connection

Select the corresponding terminal based on the encoder type (such as A+/A -, B+/B -).

Wiring requirements:

Use shielded cables with both ends of the shielding layer grounded.

The encoder cable should be kept at least 100mm away from the power cord to avoid interference.

Maximum cable length: push-pull encoder ≤ 100m, differential encoder ≤ 300m.

Electrical connection

1. Power connection

The module is powered internally by the frequency converter and does not require additional power supply.

2. Fiber optic communication connection

Connect the RXD (receiver) of the module to the TXD (transmitter) of the previous node to form a circular link.

The TXD of the last module needs to be connected back to the NAMC board or NDCO board of the frequency converter.

3. Encoder signal connection

Push pull encoder: directly connected to the digital input terminal of the module.

Differential encoder: Connected after conversion by a differential receiver.

Troubleshooting

communication failure

Check if the fiber optic connection is secure and if the interface is clean.

Confirm that there are no conflicts in the node numbers and that all module numbers are even.

Encoder signal loss

Check if the encoder power supply is normal (usually+5V or+24V).

Use an oscilloscope to check if the encoder output waveform is stable.

Parameter not effective

Restart the frequency converter and ensure that the parameters are saved to non-volatile memory.

Precautions

Static protection: Wear an anti-static wristband before operation to avoid touching the circuit board.

Environmental requirements: Avoid installation in damp, dusty, or strong electromagnetic interference environments.

Maintenance: Regularly clean the module's heat dissipation holes and check for dust or damage to the fiber optic interface.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands