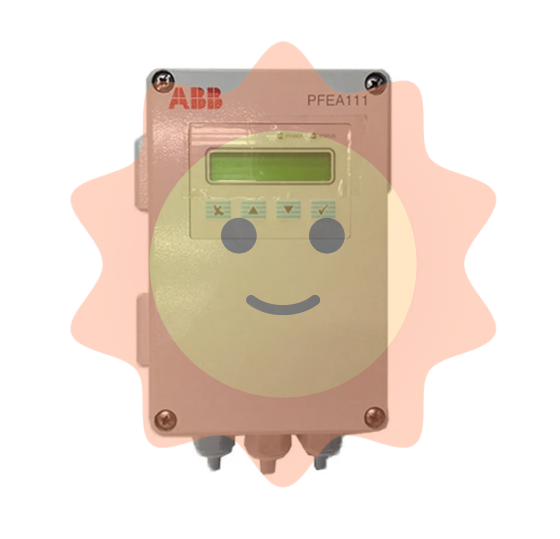

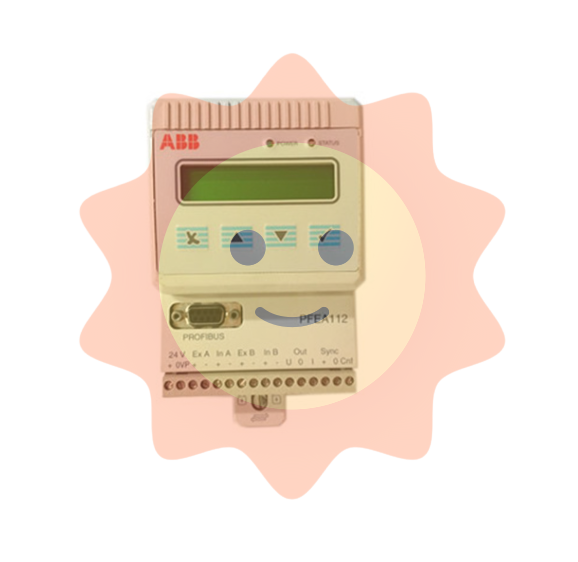

ABB LD 810HSE Ex Foundation fieldbus connection equipment

ABB LD 810HSE Ex Foundation fieldbus connection equipment

Core positioning and basic attributes of the product

(1) Product identity and functional positioning

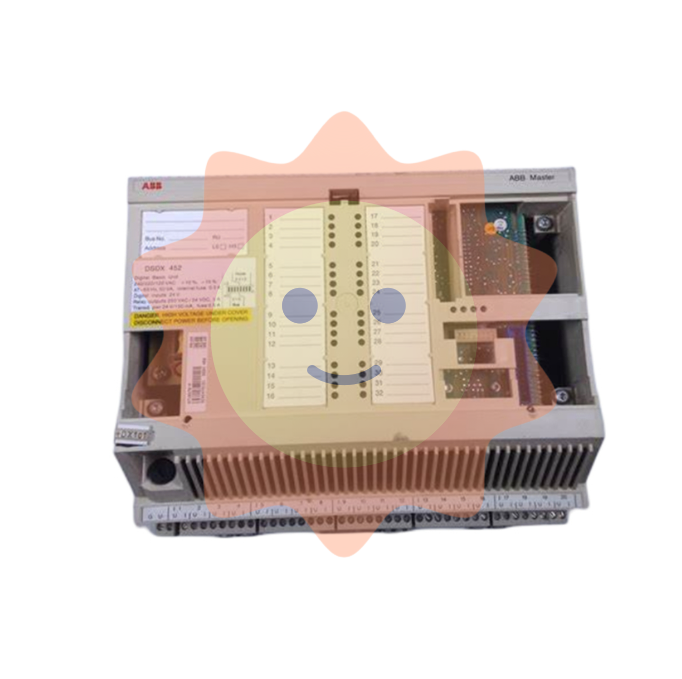

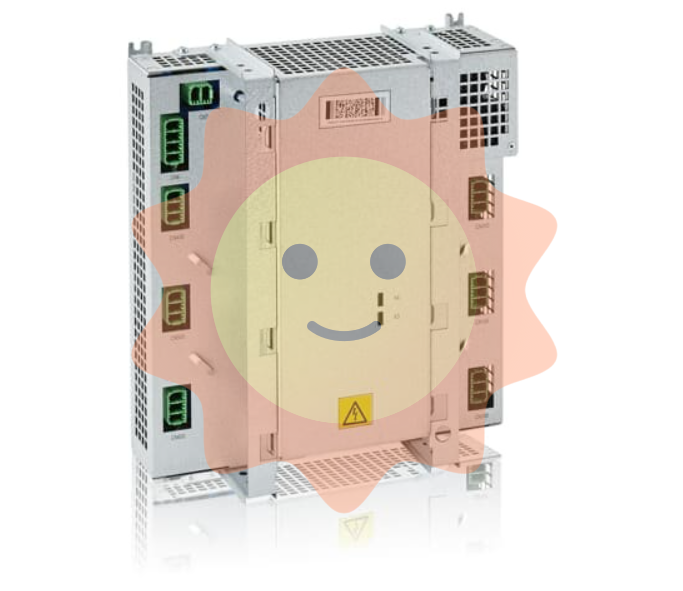

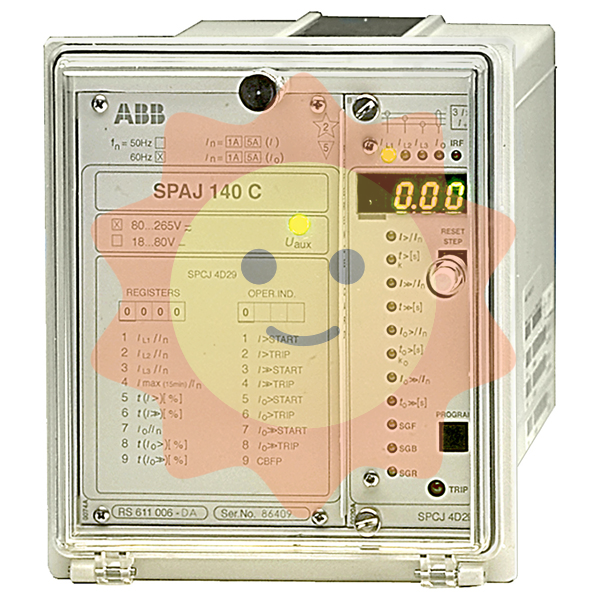

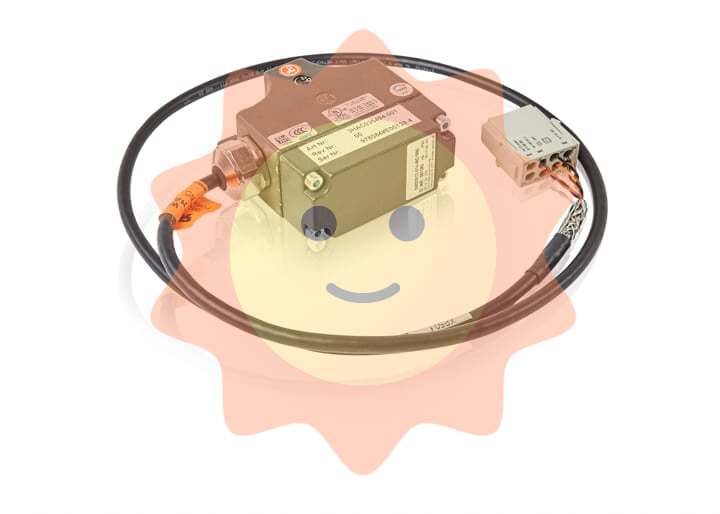

ABB LD 810HSE Ex is a foundation fieldbus ™ Fieldbus connects devices and is registered as a 42c class device according to the HSE protocol specification. Its core function is to serve as a gateway between the FF high-speed Ethernet (FF-HSE) subnet and the FF-H1 link, enabling data exchange and device management between different bus types. It also supports device redundancy and ensures communication stability in industrial control scenarios.

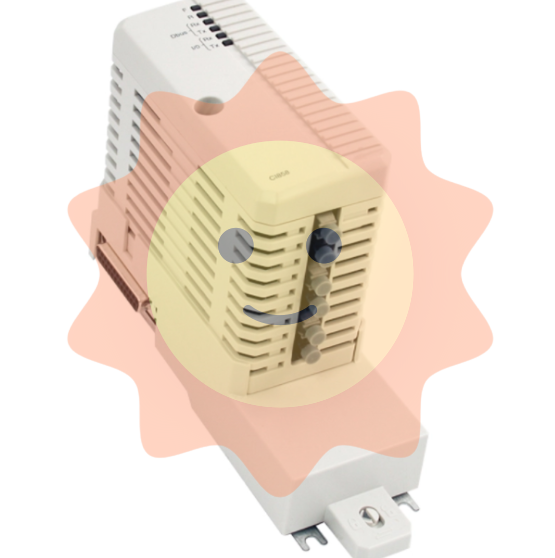

(2) Physical and installation characteristics

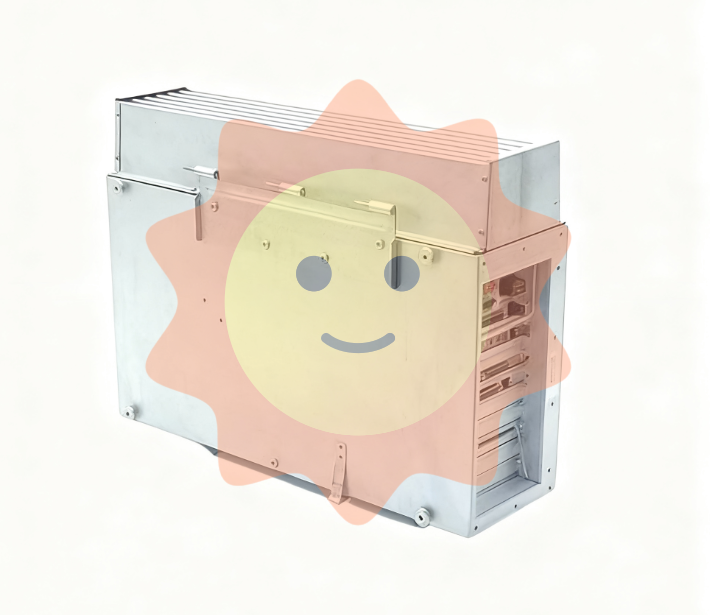

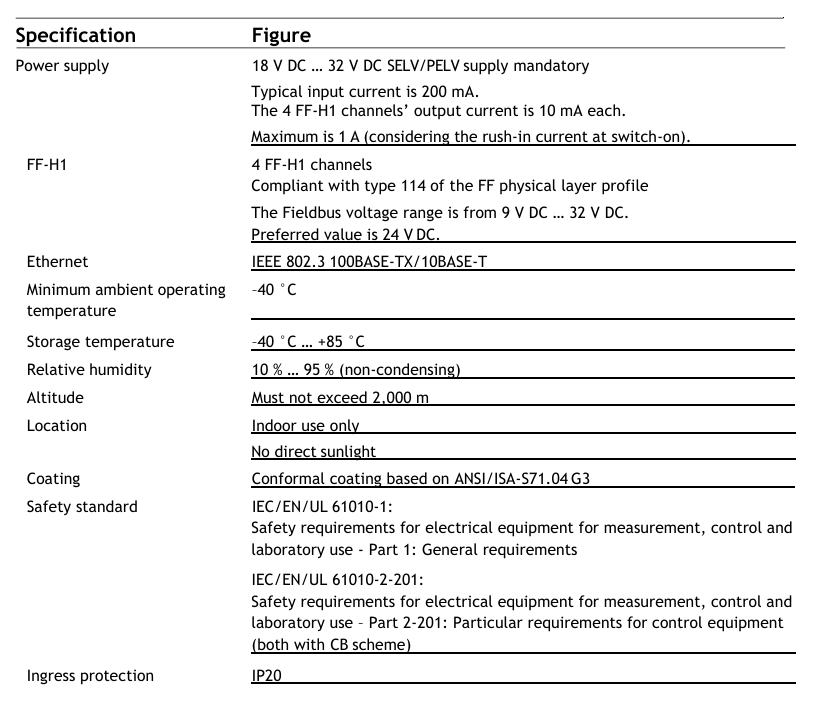

Protection level: IP20, only suitable for indoor environments, must avoid direct sunlight, and has no impact protection or IP54 protection capability. When installed in hazardous areas, it must be equipped with a protective shell that meets the requirements of IEC/EN 60079-0 Section 26.4 (with impact resistance and corresponding IP level).

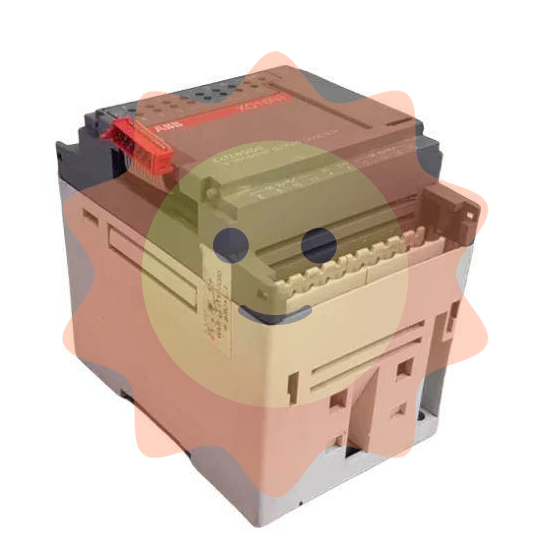

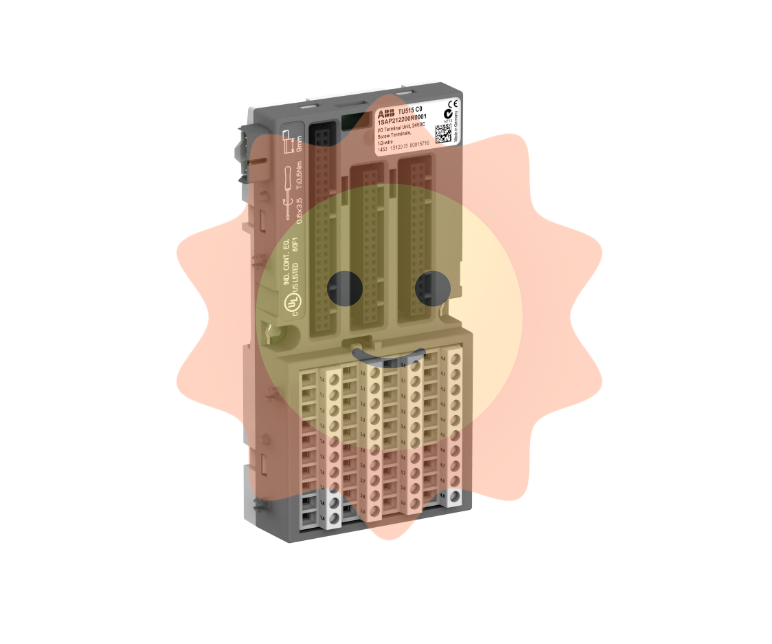

Installation method: DIN rail installation, suitable for standardized installation scenarios inside industrial control cabinets.

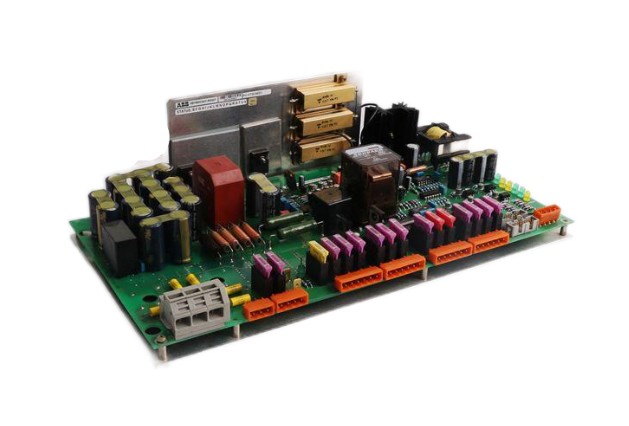

Power supply requirements: 24V DC power supply is required (power supply range 18V DC -32V DC, and must be SELV/PELV power supply), with a typical input current of 200mA, 4 FF-H1 channels each with an output current of 10mA, and a maximum current of 1A (including startup surge current).

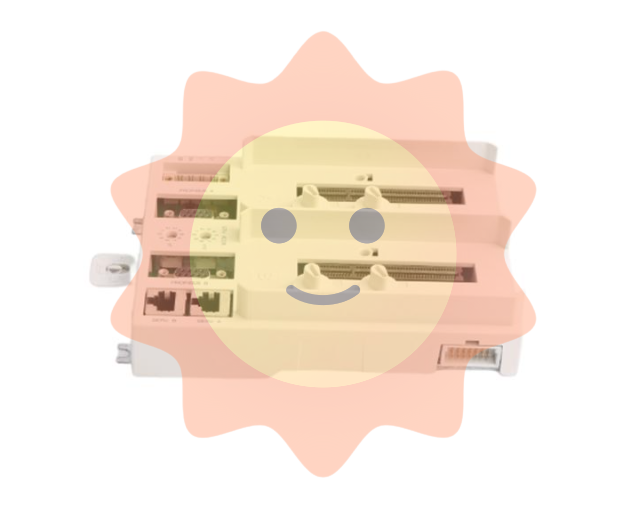

Core functions and communication capabilities

(1) Gateway core functions

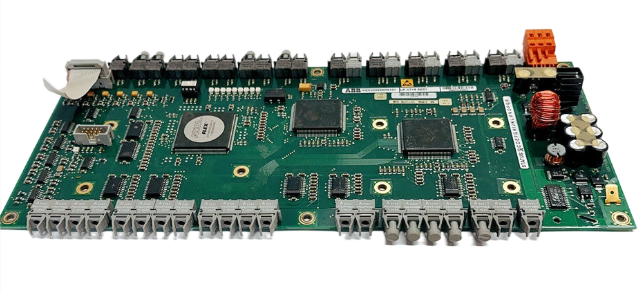

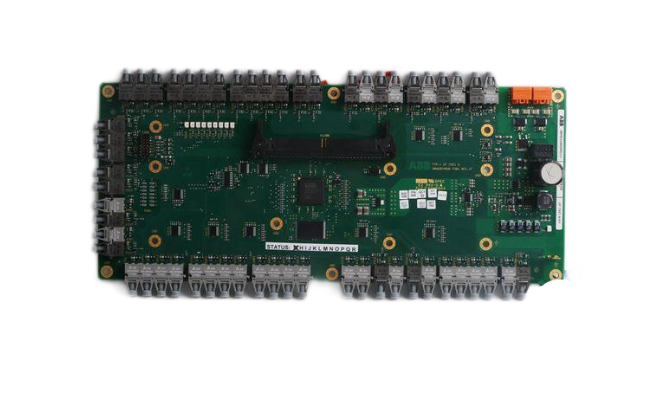

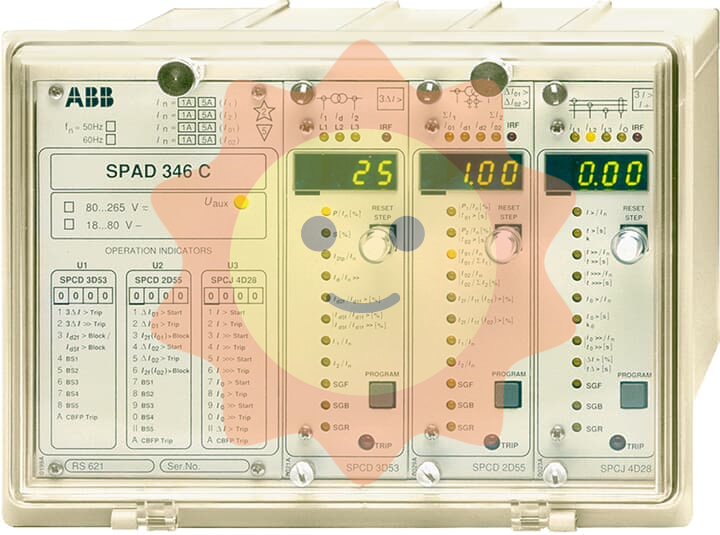

H1 Link Management: Supports up to 4 independent FF-H1 links, and devices in each link can act as Link Masters and SM Time Publishers, responsible for identifying devices connected to the H1 link, configuring system and network management for H1 devices through HSE, and accessing the functional blocks of H1 devices.

Data forwarding and alarm distribution: Implement process data forwarding between H1 links, bidirectional process data forwarding between H1 and HSE subnets, and distribution of alarms and events sent by H1 devices to ensure efficient flow of industrial process data between different bus levels.

HSE side management function: integrates System Management Agent, Network Management Agent, and FMS server (providing H1 device object access capability), supports Simple Network Time Protocol (SNTP) servers based on HSE specifications (for SM time synchronization), but does not support Simple Network Management Protocol (SNMP); Maintenance functions can be implemented through a web server, including firmware updates for connecting devices and H1 power modules (supporting http/https protocol).

(2) Communication performance and limitations

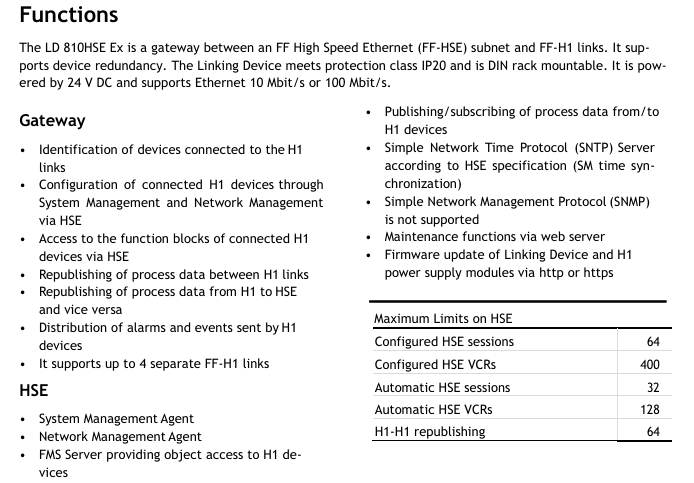

1. Maximum limit on HSE side

Indicator values

64 HSE sessions have been configured

400 HSE virtual communication relationships (VCRs) have been configured

Automatic HSE session count 32

128 automatic HSE virtual communication relationships (VCRs)

H1-H1 data forwarding count 64

2. Maximum limit for a single H1 channel

Explanation of Indicator Values

The total number of VCRs (VCRs) for source/sink, client/server, and publisher/subscriber types in a single H1 channel must not exceed 128

Number of overnight connections (alarm reception) 10-

Number of clients+servers 39+1-

100 publishers and subscribers-

LAS scheduling table number 2-

Number of sub scheduling tables 4-

The number of sequences in each sub schedule table is 64-

The number of elements in each sequence is 4-

LAS scheduling table field size 2000 bytes-

3. Other communication characteristics

H1 Link: Supports H1 Live List, which records device node addresses, PD tags, and device IDs; supports access to H1 port MIB (Management Information Base), but restricts write permissions on the H1 network side; The FF-H1 physical layer complies with Class 114 specifications, with a fieldbus voltage range of 9V DC to 32V DC (recommended 24V DC).

Ethernet: Compatible with IEEE 802.3 standard, supporting speeds of 10Mbit/s or 100Mbit/s, meeting the communication needs of industrial Ethernet.

Applicability and Compliance of Hazardous Areas

(1) Dangerous Area Certification and Applicable Scenarios

1. North American Certification (cULus)

If the device label indicates relevant information, it can be used for Class 1, Division 2, A/B/C/D hazardous areas, or non hazardous areas.

2. European and international certifications (ATEX, IECEx)

Applicable standards: evaluated according to IEC 60079-0:2011 (revised 6, including 2012/2013 revisions), IEC 60079-11:2011 (revised 6, including 2012 revisions), IEC 60079-15:2010 (revised 4), and corresponding EN standards.

Applicable to hazardous areas: If the equipment label or technical documentation indicates relevant information, it can be used in Zone 2 gas explosion environments with IIA/IIB/IIC explosion groups and T4 temperature levels when paired with tested enclosures.

Explosion proof marking: IECEx marking is "Ex nA [ic] IIC T4 Gc", ATEX marking is "II3G nA [ic] IIC T4 Gc", where the "[ic]" explosion-proof method is only applicable to the FF-H1 fieldbus interface; Comply with the requirements of Directive 2014/34/EU and strictly follow the hazardous area system installation standards such as IEC/EN 60079-14 during installation.

(2) Other Compliance

Safety standards: Compliant with IEC/EN/UL 61010-1 (Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use - Part 1: General Requirements) and IEC/EN/UL 61010-2-201 (Part 2-201: Special Requirements for Control Systems), and certified by the CB system.

Coating standard: The conformal coating complies with ANSI/ISA-S71.04 G3 standard, enhancing the equipment's ability to resist environmental interference.

System integration and environmental adaptability

(1) ABB Ability ™ IT system integration

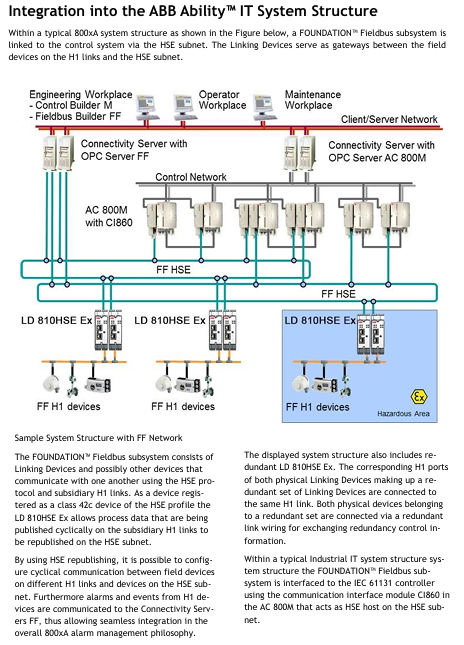

Typical integration architecture: In the ABB 800xA system, the Foundation fieldbus subsystem is connected to the control system through the HSE subnet, and LD 810HSE Ex serves as the gateway between the H1 link field equipment and the HSE subnet; The AC 800M controller interacts with the HSE subnet through the communication interface module CI860 (as the HSE host), and the engineering workstation (Control Builder M), operation and maintenance workstation, etc. access fieldbus data through FF connection servers (with OPC servers).

Redundancy integration: Supports LD 810HSE Ex device redundancy, where the corresponding H1 ports of redundant devices are connected to the same H1 link, and redundant control information is exchanged through redundant link wiring to enhance system reliability; The periodic process data on the H1 link can be forwarded to the HSE subnet through HSE, enabling periodic communication between different H1 link devices and HSE subnet devices. At the same time, H1 device alarms and events can be uploaded to the FF connection server and integrated into the 800xA system alarm management system.

(2) Environmental adaptation parameters

Scope of environmental indicators

Working temperature -40 ° C -+70 ° C

Storage temperature -40 ° C -+85 ° C

Relative humidity 10% -95% (non condensing)

Altitude not exceeding 2000m

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com