Schneider ELAU PacDrive C400/C400 A8 Controller

Hardware specifications and environmental adaptability

1. Electrical and mechanical parameters

Category specific specifications

The power requirement is DC 24V (-15%~+25%), with a maximum current of 3A without UPS and 4.5A with UPS. The maximum power consumption is 85W

The protection level of the shell is IP20, suitable for installation inside the control cabinet; Pollution level 2, suitable for industrial dust environment

Size and weight: Packaging size 300 × 130 × 400mm (D × W × H), with packaging weight of 3.5kg (C400)/4.1kg (C400 A8)

Isolation and anti-interference comply with the IEC 61000-6-2 electromagnetic interference standard, supporting shielded cable connections to reduce signal interference

Diagnostic and monitoring alphanumeric diagnostic display screen, status LED indicator light; Watchdog function (maximum 60V/2A), triggers relay in case of malfunction

2. Environmental adaptability

Scene temperature range, humidity range, and other requirements

Normal operation+5 ℃~+45 ℃ (C400); +5 ℃~+40 ℃ (with UPS) 5%~85% RH (no condensation) No freezing or water ingress allowed

Transportation -25 ℃~+70 ℃ (C400); -25 ℃~+50 ℃ (with UPS) 5%~95% RH (without condensation) Prohibited from severe vibration (compliant with IEC 60721-3-2 2K3 level)

Long term storage (inside packaging) -25 ℃~+55 ℃ (C400); -5 ℃~+45 ℃ (with UPS) 5%~95% RH (no condensation) Prohibited corrosive gas environment

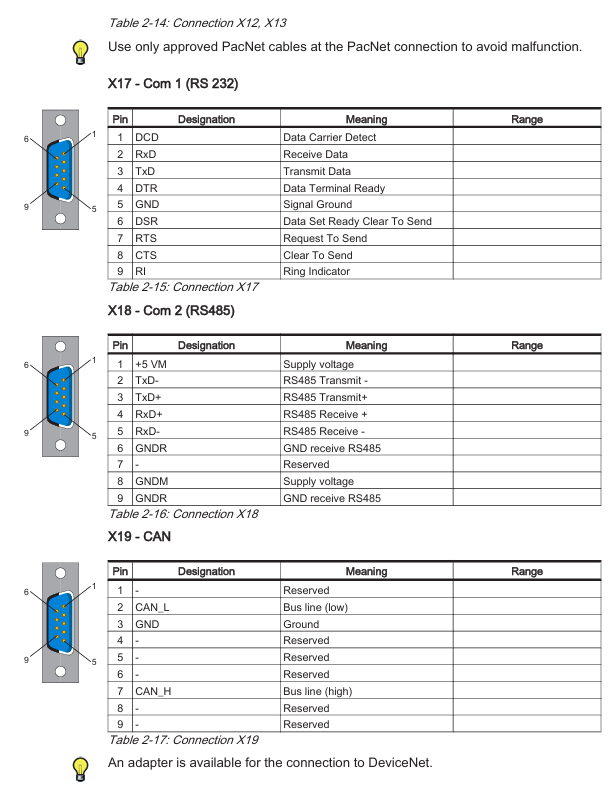

Interface configuration and wiring specifications

1. Core interface layout

The controller panel consists of 20 interfaces (X1~X20), and the core interface functions and wiring requirements are as follows:

Interface number, interface type, functional description, wiring specifications

X1 control power supply/watchdog connected to DC 24V power supply, outputting watchdog relay signal; Shielded cable is required for terminal cross-sectional area of 1.5mm ² (AWG 16-28), and the positive and negative poles of the power supply should be distinguished

X2 digital output with 16 channels of DC 20-30V output, terminal cross-sectional area of 1.5mm ². The output terminal needs to be equipped with a fuse according to the load

X3 digital input with 20 channels of DC 20-33V input, terminal cross-sectional area of 1.5mm ². The input signal needs to match the sensor output type

X4 Touchprobe/Fast Input 16 Touchprobe inputs+4 Fast Interrupt inputs, with a terminal cross-sectional area of 1.5mm ². High speed signals require twisted pair shielded cables

X5 analog I/O 2-channel analog input (-10~10V/0~20mA)+2-channel analog output (-10~10V), with a terminal cross-sectional area of 1.5mm ². Analog signals need to be wired separately to avoid interference

X10 Ethernet RJ45 interface (10/100Base-T), supports TCP/IP protocol for connecting HUB with direct Ethernet cable and connecting PC with crossover Ethernet cable

The X11 main encoder supports SinCos (+9V power supply) or incremental (+5V power supply) encoders, with a terminal cross-sectional area of 0.25mm ². The encoder signal needs to be twisted pair shielded to avoid noise

The X14/X15 SERCOS bus is connected to the real-time motion bus of the servo drive, supporting a 16MBaud rate and requiring the use of SERCOS dedicated shielded twisted pair cables

X20 PROFIBUS DP 9-pin D-type interface, master/slave mode, maximum 12MBaud rate requires the use of PROFIBUS dedicated connectors (with terminal resistors)

2. Wiring precautions

Power wiring: The DC 24V power supply of X1 interface needs to be supplied separately to avoid sharing the circuit with other high-power devices and prevent voltage fluctuations from affecting the stability of the controller.

Shielding treatment: All analog signals, encoder signals, and SERCOS bus cables need to be single ended grounded (on the control cabinet side), and the shielding layer should tightly wrap around the cable to reduce electromagnetic interference.

Bus terminal resistance: Terminal resistance (120 Ω) should be enabled at the beginning and end nodes of PROFIBUS DP and CAN bus to ensure the integrity of the bus signal; The intermediate node needs to turn off the terminal resistor.

Compliance certification

Safety and compliance certification

Safety certification: Complies with CE, UL, and cUL certification standards, and meets the industrial equipment safety requirements of the European Union (EN) and North America (UL).

Electromagnetic compatibility (EMC): Complies with IEC 61000-6-2 (anti-interference in industrial environments) and EN 55011 (radiation limits) standards, and can operate stably in strong electromagnetic environments such as high-voltage motors and frequency converters.

Environmental standards: Complies with the IEC/EN 60721-3 series standards and adapts to temperature and humidity changes in industrial settings.

Product Model and Selection

1. Model differentiation

Model Core Differences Order Number Applicable Scenarios

PacDrive C400 supports 16 SERCOS slaves, Pentium M processor 13130261 for multi axis complex motion scenes (such as 16 axis packaging machines)

The PacDrive C400 A8 supports 8 SERCOS slaves, and the Celeron M processor 13130261-001 is suitable for low to medium axis scenarios (such as 8-axis assembly lines)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands