Emerson PR6426 32mm Eddy Current Sensor

Emerson PR6426 32mm Eddy Current Sensor

Product positioning and application

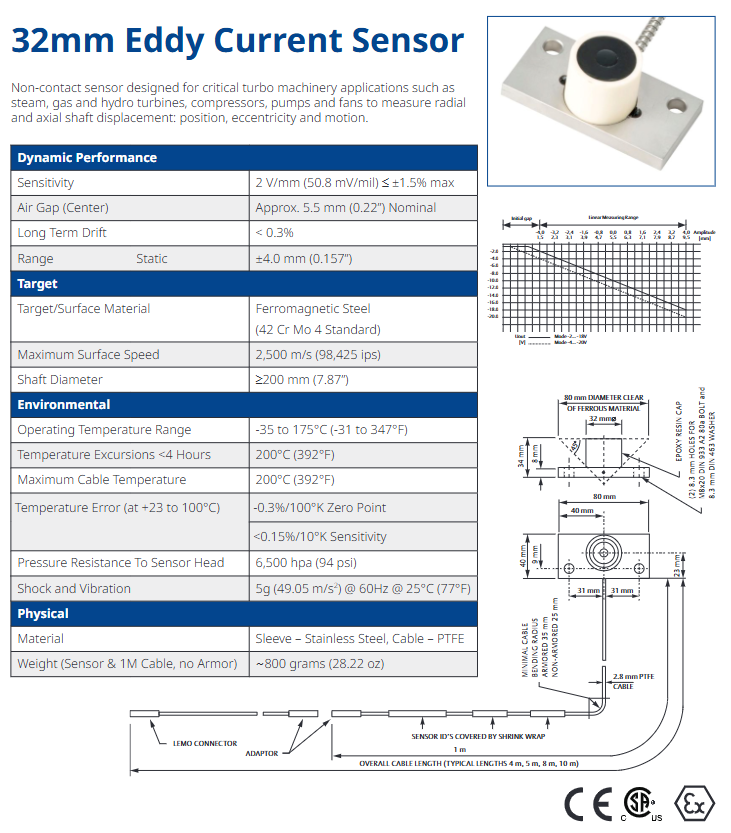

PR6426 is a non-contact 32mm eddy current sensor designed for critical turbomachinery applications, which can be used to measure radial and axial shaft displacement, including position, eccentricity, and motion. It is suitable for equipment including steam turbines, gas turbines, water turbines, compressors, pumps, and fans.

Core performance parameters

(1) Dynamic performance

Specific specifications of parameters

Sensitivity 2 V/mm (50.8 mV/mil), maximum deviation ≤± 1.5%

The nominal air gap (center) is approximately 5.5 mm (0.22 inches)

Long term drift<0.3%

Static measurement range ± 4.0 mm (0.157 inches)

(2) Target requirements

Target/Surface Material: Ferromagnetic Steel (Standard 42 Cr Mo 4)

Maximum surface velocity: 2500 m/s (98425 ips)

Shaft diameter: ≥ 200 mm (7.87 inches)

Environmental adaptability

Environmental parameter specification requirements

Working temperature range -35 to 175 ° C (-31 to 347 ° F)

Short term (<4 hours) temperature fluctuation up to 200 ° C (392 ° F)

The maximum temperature of the cable is 200 ° C (392 ° F)

Temperature error (23 to 100 ° C) Zero point: -0.3%/100 ° K; Sensitivity:<0.15%/10 ° K

Sensor head pressure resistance 6500 hPa (94 psi)

Anti impact and vibration performance 5g (49.05 m/s ²) at 60Hz, 25 ° C (77 ° F)

Physical characteristics

Material: The sleeve is made of stainless steel, and the cable is made of polytetrafluoroethylene (PTFE)

Weight: Approximately 800 grams (28.22 ounces) of sensor and 1 meter of unarmored cable

Cable related: made of 2.8mm PTFE cable; The minimum bending radius of armored cables is 31mm, and the minimum bending radius of non armored cables is 25mm. The standard total cable length is 1 meter, and there are also typical lengths such as 4 meters, 5 meters, 8 meters, and 10 meters to choose from

Structural details: A 80mm diameter non-magnetic material free area needs to be reserved; Equipped with LEMO connector adapter; The sensor identification is covered by a heat shrink tubing; There are 2 8.3mm holes for installing M8 × 20 DIN 933 A2 80A bolts and 8.3mm DIN 463 washers; The end is an epoxy resin cap

Compliance and Certification

Certification type follows standards

CE certification 2014/30/EU (EN 61326-1), 2014/34/EU, 2011/65/EU

ATEX certification EN 60079-0, EN 60079-11

IEC Ex certification IEC 60079-0, IEC 60079-11, IEC 60079-26

CSA Certification CAN/CSA-C22.2 NO. 0-M91、CAN/CSA-C22.2 NO. 157-92、CAN/CSA-C22.2 NO. 213-M1987、CAN/CSA-E60079-15-02(R2006)、CAN/CSA-C22.2 NO. 25-1966、CAN/CSA-C22.2 NO. 61010-1-04、ANSI/UL Standard 913-2004、ANSI/UL Standard 1604-1995、UL 60079-15 2002、UL 61010-1

Hazardous Area Certification

Inherent Safety (iA)

Certification system requirements

The ATEX/IEC Ex area classification depends on the converter, as detailed in the converter documentation; Sensor temperature classification: T6 (Ta ≤ 84 ° C), T4 (Ta ≤ 114 ° C), T3 (Ta ≤ 160 ° C)

The classification of CSA regions depends on the converter, as detailed in the converter documentation; Sensor temperature classification: T6 (Ta ≤ 64 ° C), T4 (Ta ≤ 114 ° C), T3 (Ta ≤ 160 ° C)

The document does not mention specific and detailed requirements.

Order Matrix

The order model format is PR6426/X X X - X X X, and the meaning of each location code is as follows:

Sleeve thread: No thread (code 0)

Armored cable: with armor (code 1), without armor (code 0)

Total sensor length: mounting plate 80mm × 40mm (code 0)

Adapter plug: No adapter plug (code 0), with adapter plug (code 1)

Total cable length: 4 meters (code 0), 5 meters (code 1), 6 meters (code 2), 8 meters (code 3), 10 meters (code 4)

Cable end: LEMO interface (code 0), open (code 1)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands