Schneider ELAU PacDrive C400/C400 A8 Controller

Schneider ELAU PacDrive C400/C400 A8 Controller

Product core positioning and system architecture

1. Core positioning

The PacDrive C400/C400 A8 is a high-performance motion controller based on a real-time operating system, designed specifically for industrial equipment that requires multi axis synchronization and precise positioning. Its core function is to coordinate servo drives to complete complex motion control tasks (such as cam synchronization, electronic gears, and multi axis interpolation), while supporting logic control and industrial communication, and adapting to automated production lines such as packaging, printing, and assembly.

2. System architecture

Hardware Core: Equipped with Intel processors (C400 for Pentium M 600MHz, C400 A8 for Celeron M 600MHz), 256MB RAM, 128kB NVRAM, and ≥ 128MB CompactFlash card (for program storage and data backup), ensuring real-time computation and data stability.

Real time operating system: Equipped with VxWorks real-time system, it has fast response speed, supports multitasking parallel processing, and meets the demand for "microsecond level" real-time performance in motion control.

Core bus: Connected to servo drives through SERCOS real-time motion bus (C400 supports up to 16 SERCOS slave stations, C400 A8 supports up to 8), achieving multi axis synchronous control; Simultaneously equipped with fieldbus such as PROFIBUS DP and CANopen, balancing logic control and device interconnection.

Core functions and technical features

1. Motor control ability

Multi axis control: C400 supports 16 servo axes, and C400 A8 supports 8 servo axes. All axes are compatible with full cycle control of SERCOS bus (such as 1ms/2ms/4ms cycle), which can achieve complex movements such as electronic gear, electronic cam, and multi axis interpolation, meeting high-precision synchronization requirements (such as film traction and cutter synchronization of packaging machines).

Cam and sequence control: Supports up to 256 dynamic cam groups, and cam curves can be customized through software; Sequence control supports three modes of "continuous/cycle/event triggering", adapted to the step-by-step action logic of the production line (such as workstation switching on the assembly line).

Position detection and feedback: equipped with 1 SinCos main encoder interface and 1 incremental main encoder interface (X11), supporting external position feedback; Simultaneously providing 16 Touchprobe trigger inputs (X4) with a resolution of 100 μ s, it can achieve precise positioning capture (such as product positioning detection).

2. Logic control and I/O expansion

PLC function: Supports IEC 61131-3 standard programming language (instruction list IL, ladder diagram LD, function block diagram FBD, structured text ST, etc.), can simultaneously handle motion control and logic control tasks (such as equipment start stop, safety interlock, fault diagnosis); PLC instruction execution speed is fast, with only 7 μ s required for 1000 instructions and a fast task cycle of up to 250 μ s.

Local I/O configuration:

Digital input: 20 channels (DC 20-33V, supporting 1/5ms parameterized filtering), used for detecting sensor signals (such as photoelectric switches, limit switches).

Digital output: 16 channels (DC 20-30V, rated current 250mA per channel, short circuit protection), used to control actuators (such as solenoid valves, indicator lights).

Analog I/O: 2 analog inputs (-10~10V or 0~20mA, 12 bit resolution), 2 analog outputs (-10~10V, 12 bit resolution), compatible with analog devices such as pressure sensors and proportional valves.

Fast I/O: 4-channel interrupt input (X4, 0.1/1ms filtering), used to process high-speed trigger signals (such as emergency stop, safety door signals).

Scalability: Up to 128 digital inputs/outputs and 128 Touchprobe inputs can be expanded through the PacNet interface; Through PROFIBUS DP, 126 slave stations can be connected, with a maximum expansion of 3584 bytes of digital/analog I/O, meeting the signal acquisition and control requirements of large-scale production lines.

3. Industrial communication and data exchange

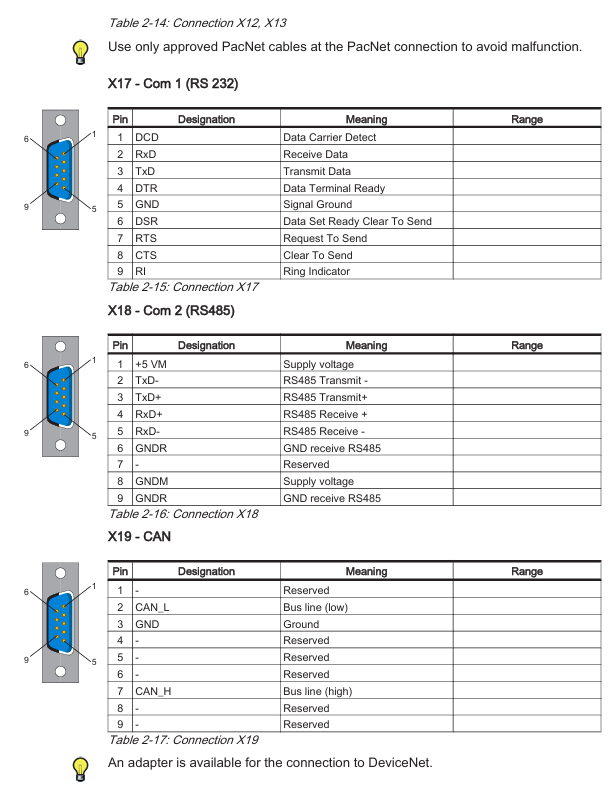

Communication interface:

Motion bus: SERCOS (16MBaud), used for connecting servo drives to achieve multi axis synchronization.

Fieldbus: PROFIBUS DP (master/slave mode, 12MBaud), CANopen, DeviceNet (adapter required), EtherNet/IP (optional hardware module required), supporting interconnection with PLC, HMI, sensors and other devices.

General communication: RS232 (COM1), RS485 (COM2), Ethernet (10/100Base-T, supporting TCP/IP), used for program download, data monitoring, and remote maintenance.

Data exchange and remote services:

Built in OPC server, supports real-time data access for Windows based HMI (such as Schneider Vijeo Designer), and realizes device status visualization.

Support remote services between web servers and modems, enabling device diagnostic information to be obtained through browsers or SMS (SMTP protocol), simplifying on-site maintenance.

Integrated data logger (27kB) and trajectory logger (8 channels, 1ms resolution), capable of recording fault information and motion curves for troubleshooting and process optimization.

Hardware specifications and environmental adaptability

1. Electrical and mechanical parameters

Category specific specifications

The power requirement is DC 24V (-15%~+25%), with a maximum current of 3A without UPS and 4.5A with UPS. The maximum power consumption is 85W

The protection level of the shell is IP20, suitable for installation inside the control cabinet; Pollution level 2, suitable for industrial dust environment

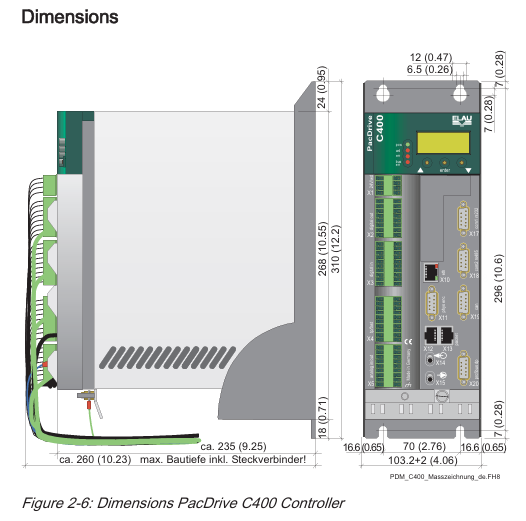

Size and weight: Packaging size 300 × 130 × 400mm (D × W × H), with packaging weight of 3.5kg (C400)/4.1kg (C400 A8)

Isolation and anti-interference comply with the IEC 61000-6-2 electromagnetic interference standard, supporting shielded cable connections to reduce signal interference

Diagnostic and monitoring alphanumeric diagnostic display screen, status LED indicator light; Watchdog function (maximum 60V/2A), triggers relay in case of malfunction

2. Environmental adaptability

Scene temperature range, humidity range, and other requirements

Normal operation+5 ℃~+45 ℃ (C400); +5 ℃~+40 ℃ (with UPS) 5%~85% RH (no condensation) No freezing or water ingress allowed

Transportation -25 ℃~+70 ℃ (C400); -25 ℃~+50 ℃ (with UPS) 5%~95% RH (without condensation) Prohibited from severe vibration (compliant with IEC 60721-3-2 2K3 level)

Long term storage (inside packaging) -25 ℃~+55 ℃ (C400); -5 ℃~+45 ℃ (with UPS) 5%~95% RH (no condensation) Prohibited corrosive gas environment

Interface configuration and wiring specifications

1. Core interface layout

The controller panel consists of 20 interfaces (X1~X20), and the core interface functions and wiring requirements are as follows:

Interface number, interface type, functional description, wiring specifications

X1 control power supply/watchdog connected to DC 24V power supply, outputting watchdog relay signal; Shielded cable is required for terminal cross-sectional area of 1.5mm ² (AWG 16-28), and the positive and negative poles of the power supply should be distinguished

X2 digital output with 16 channels of DC 20-30V output, terminal cross-sectional area of 1.5mm ². The output terminal needs to be equipped with a fuse according to the load

X3 digital input with 20 channels of DC 20-33V input, terminal cross-sectional area of 1.5mm ². The input signal needs to match the sensor output type

X4 Touchprobe/Fast Input 16 Touchprobe inputs+4 Fast Interrupt inputs, with a terminal cross-sectional area of 1.5mm ². High speed signals require twisted pair shielded cables

X5 analog I/O 2-channel analog input (-10~10V/0~20mA)+2-channel analog output (-10~10V), with a terminal cross-sectional area of 1.5mm ². Analog signals need to be wired separately to avoid interference

X10 Ethernet RJ45 interface (10/100Base-T), supports TCP/IP protocol for connecting HUB with direct Ethernet cable and connecting PC with crossover Ethernet cable

The X11 main encoder supports SinCos (+9V power supply) or incremental (+5V power supply) encoders, with a terminal cross-sectional area of 0.25mm ². The encoder signal needs to be twisted pair shielded to avoid noise

The X14/X15 SERCOS bus is connected to the real-time motion bus of the servo drive, supporting a 16MBaud rate and requiring the use of SERCOS dedicated shielded twisted pair cables

X20 PROFIBUS DP 9-pin D-type interface, master/slave mode, maximum 12MBaud rate requires the use of PROFIBUS dedicated connectors (with terminal resistors)

2. Wiring precautions

Power wiring: The DC 24V power supply of X1 interface needs to be supplied separately to avoid sharing the circuit with other high-power devices and prevent voltage fluctuations from affecting the stability of the controller.

Shielding treatment: All analog signals, encoder signals, and SERCOS bus cables need to be single ended grounded (on the control cabinet side), and the shielding layer should tightly wrap around the cable to reduce electromagnetic interference.

Bus terminal resistance: Terminal resistance (120 Ω) should be enabled at the beginning and end nodes of PROFIBUS DP and CAN bus to ensure the integrity of the bus signal; The intermediate node needs to turn off the terminal resistor.

Compliance certification

Safety and compliance certification

Safety certification: Complies with CE, UL, and cUL certification standards, and meets the industrial equipment safety requirements of the European Union (EN) and North America (UL).

Electromagnetic compatibility (EMC): Complies with IEC 61000-6-2 (anti-interference in industrial environments) and EN 55011 (radiation limits) standards, and can operate stably in strong electromagnetic environments such as high-voltage motors and frequency converters.

Environmental standards: Complies with the IEC/EN 60721-3 series standards and adapts to temperature and humidity changes in industrial settings.

Product Model and Selection

1. Model differentiation

Model Core Differences Order Number Applicable Scenarios

PacDrive C400 supports 16 SERCOS slaves, Pentium M processor 13130261 for multi axis complex motion scenes (such as 16 axis packaging machines)

The PacDrive C400 A8 supports 8 SERCOS slaves, and the Celeron M processor 13130261-001 is suitable for low to medium axis scenarios (such as 8-axis assembly lines)

2. Selection suggestions

Axis requirement: Select the number of servo axes according to the production line (C400 adaptation ≤ 16 axes, C400 A8 adaptation ≤ 8 axes), and reserve 1-2 spare axis positions for later expansion.

Function extension: If EtherNet/IP communication or UPS uninterruptible power supply is required, the corresponding optional module needs to be selected; If a large amount of I/O expansion is required, priority should be given to using PacNet or PROFIBUS DP expansion to avoid insufficient local I/O resources.

Environmental adaptation: If the temperature in the application scenario is below+5 ℃ or above+45 ℃, additional temperature control devices (such as control cabinet air conditioning) need to be configured to ensure that the controller operates within the rated temperature range.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands