How to install and maintain the ABB CP450 Human Machine Interface (HMI)?

Display and interaction: Equipped with a 10.4-inch TFT color LCD screen (64K colors, 640 × 480 pixels), analog touch screen, backlight life of about 50000 hours (at 25 ° C environment), supports 80 × 60 characters (8 × 8 fonts) display, and can ensure operational accuracy through touch screen calibration.

Protection level: The front panel meets IP65/NEMA 4X standards (for indoor use only), is dustproof and waterproof, and is suitable for industrial pollution level 2 environments (moderate dust, no strong corrosive gases).

Compatibility and development tools: Application programs need to be designed using CP400Soft software, supporting compatibility with multiple HMI models and providing "plug and play" on-site device integration capabilities to reduce development difficulty.

Anti interference and stability: It has high transient anti-interference capability, meets the requirements of Article 4 of EMC Directive 2004/108/EC, and can operate stably in an environment without strong magnetic fields or drastic temperature changes (working temperature of 0-50 ° C).

ABB CP450 Human Machine Interface (HMI)

Core positioning and basic characteristics of the product

CP450 is an industrial grade human-machine interface (HMI) that focuses on high protection and flexible compatibility, suitable for scenarios such as factory automation and mechanical equipment control. Its core basic features are as follows:

Display and interaction: Equipped with a 10.4-inch TFT color LCD screen (64K colors, 640 × 480 pixels), analog touch screen, backlight life of about 50000 hours (at 25 ° C environment), supports 80 × 60 characters (8 × 8 fonts) display, and can ensure operational accuracy through touch screen calibration.

Protection level: The front panel meets IP65/NEMA 4X standards (for indoor use only), is dustproof and waterproof, and is suitable for industrial pollution level 2 environments (moderate dust, no strong corrosive gases).

Compatibility and development tools: Application programs need to be designed using CP400Soft software, supporting compatibility with multiple HMI models and providing "plug and play" on-site device integration capabilities to reduce development difficulty.

Anti interference and stability: It has high transient anti-interference capability, meets the requirements of Article 4 of EMC Directive 2004/108/EC, and can operate stably in an environment without strong magnetic fields or drastic temperature changes (working temperature of 0-50 ° C).

Safety regulations (highest priority)

1. General safety requirements

Operation qualification: Only professional personnel are allowed to install, operate, and maintain the equipment. Non professional operations may result in equipment damage or safety risks;

Installation environment: It needs to be fixedly installed on a flat surface to avoid high explosion risks, strong magnetic fields, direct sunlight, and severe temperature changes, and is only suitable for Class 1 and Class 4X (indoor) enclosures;

Foreign object protection: It is prohibited for liquids, metal debris, and wiring residue to enter the equipment opening to prevent fire or electric shock;

Equipment modification: ABB is not responsible for the modified or modified equipment, and only allows the use of components and accessories specified by ABB;

Scrap disposal: The equipment contains harmful substances such as lithium batteries, electrolytic capacitors, and display screens, which need to be recycled according to local regulations and are prohibited from being discarded at will.

2. Power and grounding safety

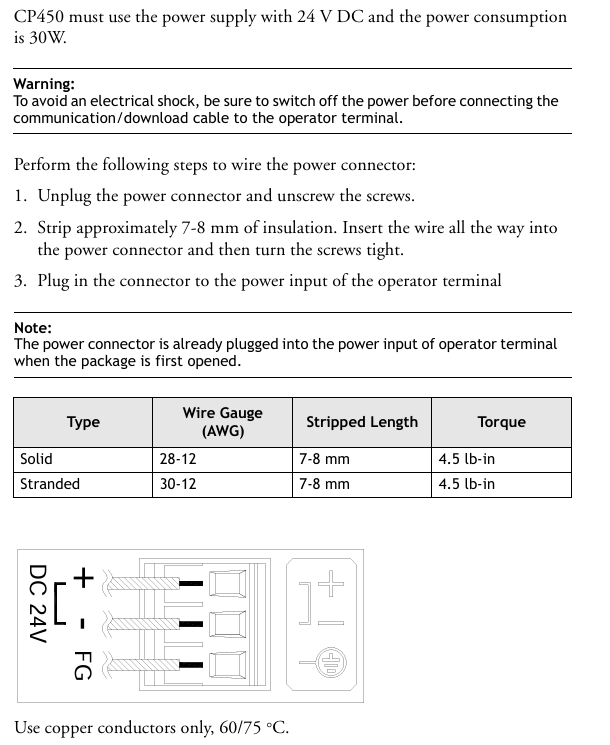

Power parameters: Only supports 24V DC ± 15% input, deviation from this range will seriously damage the equipment, and the stability of the DC power supply needs to be checked regularly, with power consumption ≤ 30W;

Grounding requirements: It must be reliably grounded (otherwise it will be severely affected by noise interference), the grounding cable must be ≥ 2mm ² (AWG 14), the grounding resistance should be ≤ 100 Ω (Class 3 grounding), and it is forbidden to share the grounding point with the power circuit;

Wiring safety: Before connecting communication/download cables, power must be cut off to avoid electric shock; The power wiring requires the use of 60/75 ° C copper conductors, with a wire stripping length of 7-8mm and a torque of 4.5lb in.

3. Use and maintain safety

Safety function limitation: Emergency stop and other safety functions cannot be controlled through CP450 and require independent design of safety circuits;

Touch screen operation: Do not touch the screen/buttons with excessive force or sharp objects to prevent damage;

Maintenance power-off: The power must be disconnected before cleaning or maintenance, and only a soft cloth dipped in neutral detergent can be used to wipe the front panel during cleaning;

Battery replacement: Built in rechargeable lithium battery (for real-time clock), ABB recommended model should be used, incorrect replacement may cause explosion.

Hardware Parameters and Component Description

1. Key physical and electrical parameters

Parameter category specific specifications

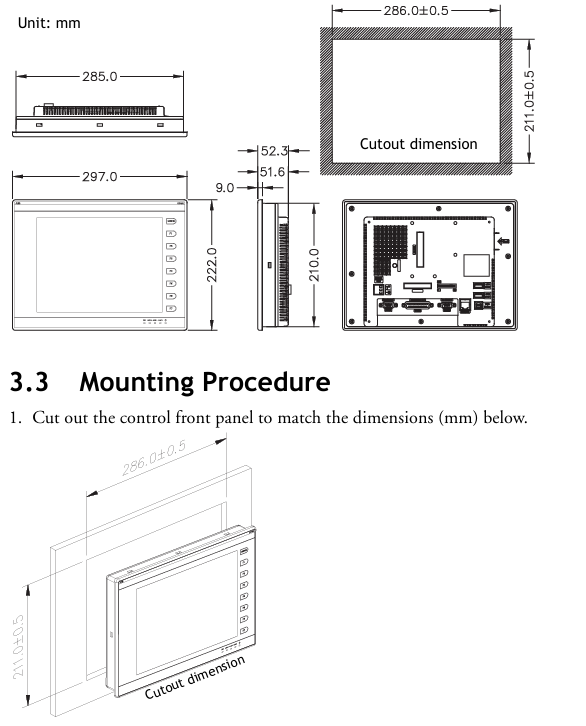

Size and Weight: Front Panel (W × H × D): 297.0 × 222.0 × 9.0mm; Installation Depth: 51.6mm; Hole Size: 286.0 × 211.0mm; Weight: 1.9kg

Storage and Memory Flash ROM 8MB, RAM 16MB, Battery Backup Memory 512KB (Data/Recipe Storage), CF Card Interface (Extended Storage)

32-bit RISC CPU with processor and clock; Real time clock (RTC, powered by lithium battery)

Environmental adaptability: working temperature of 0-50 ° C, storage temperature of -10-60 ° C; humidity of 20-90% RH (non condensing); Vibration tolerance (10~55Hz, 0.5mm displacement, 2 hours in each three-axis direction); Impact resistance (10G, 11ms, 3 times in each three-axis direction)

Certification standards CE certification (EN61000-6-4, EN61000-6-2)

2. Core component description (front/rear panel)

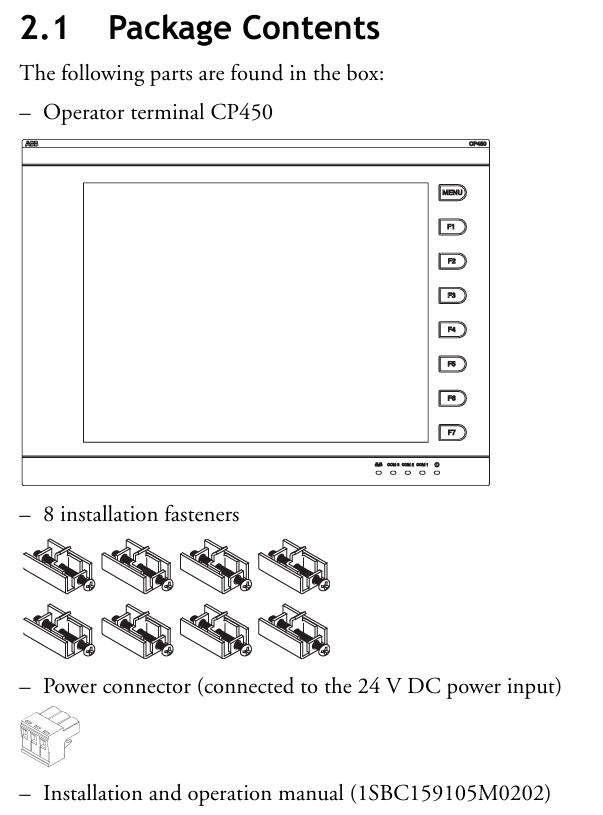

Front panel: includes fixed mounting holes, 8 function keys (1 menu key+7 F1~F7 keys), power indicator light, communication indicator light, network indicator light, 10.4-inch touch screen;

Rear panel: 24V DC power input interface, 3 communication ports (COM1~COM3), Ethernet interface, 2 USB host ports (for printer/USB flash drive), 1 USB device port (for data transmission), CF card interface, 12 bit DIP switch (for configuring working mode and communication parameters).

Installation process (including key steps)

1. Inspection of packaging list

After unpacking, it is necessary to confirm that the following components are included. If they are missing, please contact the supplier:

1 CP450 operator terminal;

8 installation fasteners;

1 24V DC power connector (pre installed on the device);

One installation and operation manual (1SBC159105M0202).

2. Opening and fixing

Panel perforation: Drill holes on the control front panel according to the size (286.0 ± 0.5mm × 211.0mm), ensuring that the edges are flat and free of burrs;

Equipment embedding: Insert CP450 into the opening and fix it to the front panel with the built-in fasteners (screws) of the equipment, with a torque controlled at 0.6~0.7 Nm (5.31~6.2 lb in), to avoid uneven force that may cause deformation of the equipment;

Installation angle: The installation angle of the equipment should be within the range of 0~135 ° (based on the display screen) to ensure the operating field of view and heat dissipation effect.

3. Grounding and power wiring

Grounding operation: Connect the grounding cable from the power connector on the rear panel of the device to an independent grounding point, ensuring that the grounding resistance is ≤ 100 Ω;

Power wiring: After disconnecting the power supply, remove the screw of the power connector, insert the stripped 24V DC wire (positive and negative poles distinguished), tighten the screw, and plug it back into the device power input interface. Copper conductors must be used and meet the wire diameter requirements (refer to safety specification 2.3).

4. Wiring requirements

Communication cables should be routed separately from power cables to avoid electromagnetic interference;

All communication cables must use shielded cables to reduce the impact of noise.

DIP switch configuration (core function switching)

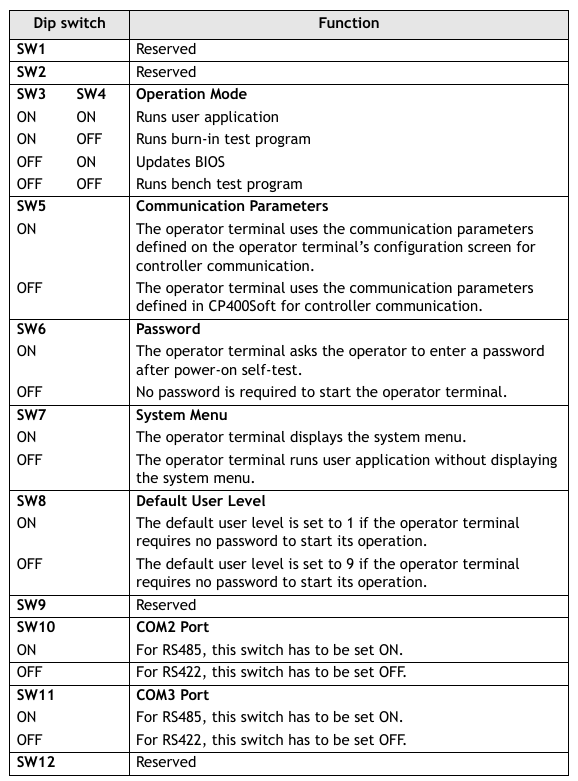

The 12 bit DIP switches (SW1-SW12) on the rear panel of CP450 are used to configure working modes, communication parameters, password requirements, etc. The key switch functions are shown in the table below (switches not labeled as "reserved" must be strictly set according to requirements):

Specific setting instructions for DIP switch function classification

SW3~SW4 working mode - ON+ON: run user applications; -ON+OFF: Run the aging test program; -OFF+ON: Update BIOS; -OFF+OFF: Run the bench test program

SW5 communication parameter source - ON: communication parameters defined using the device configuration interface; -OFF: Communication parameters defined using CP400Soft software

SW6 power on password requirement - ON: After the power on self-test, the password needs to be entered; -OFF: No password required for startup

SW7 system menu display - ON: After self-test, the system menu is displayed; -OFF: Run the user application directly without displaying the system menu

SW8 default user level - ON: When starting up without a password, the default user level is 1 (highest privilege); -OFF: Default level 9 (minimum permission)

SW10 COM2 port mode - ON: COM2 is in RS485 mode; -OFF: COM2 is in RS422 mode

SW11 COM3 port mode - ON: COM3 is in RS485 mode; -OFF: COM3 is in RS422 mode

SW1,2,9,12 retain no functionality, no need to set

Communication port configuration

CP450 provides three serial communication ports (COM1~COM3), one Ethernet port, and one USB port, supporting flexible connections with controllers and third-party devices. The key parameters are as follows:

1. Serial communication ports (COM1~COM3)

Port interface type supports protocol pin function (core) adaptation scenarios

COM1 9-pin female head RS232/RS485- RS485+(1 pin), RS485- (6 pins); -RS232 RXD (2-pin), TXD (3-pin), GND (5-pin) are connected to controllers (such as PLCs) and simple peripherals

COM2 25 pin female head RS232/RS422/RS485- RS485+/RS422 TX+(14 pins), RS485-/RS422 TX - (15 pins); -RS232 TXD (2-pin), RXD (3-pin) for connecting multiple devices and long-distance communication

COM3 9-pin female head RS422/RS485- RS485+/RS422 TX+(1 pin), RS485-/RS422 TX - (6 pins); -RS422 RX+(4-pin), RX - (9-pin) long-distance, high stability communication

Attention: The port mode needs to be matched with the DIP switch (if COM2 is RS485, set SW10=ON), otherwise communication will fail.

2. Other communication interfaces

Ethernet port: only supported by CP450 T-ETH model, used for high-speed network communication, suitable for industrial Ethernet scenarios;

USB interface: 2 USB host ports (for connecting printers and USB drives for data storage or printing), 1 USB device port (for connecting to a PC to transfer applications or recipes);

CF card interface: used for extended storage, can store application backup, recipe data, etc.

Core operational functions (including debugging and maintenance)

1. Self Test

After the device is powered on, it automatically performs hardware self-test and the screen displays the test results. The following items should be focused on:

Key detection contents: RAM, battery status, BIOS checksum, firmware checksum, application checksum, communication ports (COM1~COM3), real-time clock (RTC);

Fault handling: If a certain item displays "Failed", follow the prompts to troubleshoot (such as firmware/application verification failure requiring re download; communication port failure requiring checking wiring and DIP switch);

First use: The real-time clock (RTC) needs to be manually reset to ensure time synchronization.

2. System menu operation (SW7 needs to be set to ON)

After self checking, enter the system menu and provide 5 core functions that need to be operated through the touch screen or function keys:

System menu command function description

Link establishes communication connections between devices and external devices (such as PCs, other CP450s)

F2- Configure real-time clock (date, time) and communication parameters (baud rate, data bits, stop bits, etc.) using the directional keys to select fields and the ± key to adjust values

F3- Copy copies the application program of the current device to another CP450, requires connecting the download cable and entering the password

F4- Set calibration touch screen (touch the top left/bottom right corner and center of the screen), this operation will clear RAM data

F5- Run the user application and exit the system menu

3. Application download and upload

(1) Download the application (PC → CP450)

Hardware connection: Use TK401 cable to connect the RS232 port of the PC to COM1 of CP450, or use TK402 cable to connect COM2 (power-off wiring required);

Switch settings: Set SW7 to ON (display system menu), SW5 to be set according to the parameter source (set to ON on the device end and OFF on the software end);

Software operation: Open CP400Soft, load the application and compile it (modifications must be recompiled), select "Application/Download Firmware/Application" for the first download, and select "Application/Download Application" for subsequent downloads;

Progress monitoring: The screen displays "Programming application...", and after completion, press F5 Run to run the application.

(2) Upload application (CP450 → PC)

Connection and settings: Follow steps 1-2 of the download process to ensure that the communication parameters match;

Software operation: Select "File/Upload Application" in CP400Soft and save it as * AF6 file, enter the password set in CP400Soft (see 7.10);

File conversion: After uploading, you need to open the file through "File/Recreate Source" and save it as * V6F format, used for subsequent modifications and maintenance.

Attention: The application must be run once before the first upload, otherwise the upload function will be disabled.

4. Recipe upload/download

The formula is used to store production parameters (such as process settings), and the operation process is as follows:

Upload recipe: Set SW7 to ON, select "File/Upload Recipes" in CP400Soft, and save as * RCP file;

Download Recipe: Open the application containing the recipe in CP400Soft, select "File/Download Recipes", and choose * RCP file, run F5 Run after completion;

Prerequisite: The formula length and quantity must be defined in the application, and the existing formula format must be uploaded before editing a new formula.

5. Password management (4 scenarios)

CP450 supports multi-level password permissions to protect application and operational security. The key scenarios are as follows:

Password scene configuration method and permission instructions

The startup password (SW6=ON) is created in CP400Soft using the "Action Button" to create a password table. The registration password and user level (levels 1-9) are highest at level 1 (the password table can be modified) and lowest at level 9; You need to enter a password to start up, otherwise the application cannot run

During operation, use the "Action Button" to create a password keyboard button for permission switching. Press it and re-enter the password. Updating the user level can temporarily increase/decrease permissions (such as entering a high-level password for key functions)

Button password protection: Set permission levels for buttons (such as Goto Screen) in CP400Soft. Users with lower levels need to enter a password to restrict access to key functions (such as parameter modification and system settings)

When setting the password for copying/uploading applications (F3 Copy) or uploading applications (File/Upload Application) on the "Application/Workstation Setup" ->"Password" tab of CP400Soft, this password is required

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA