Woodward EM-80/EM-300 actuator system

Comprehensive Technical Guide to the Woodward EM-80/EM-300 All-Electric Actuator System

Introduction

In the realm of industrial prime movers, the transition from hydraulic and mechanical actuation to high-performance electric actuation represents a significant leap in control precision and reliability. The Woodward EM-80 and EM-300 actuator systems stand at the forefront of this evolution. Designed as all-electric solutions for large diesel, gas, and gasoline engines, as well as various turbine types, these systems provide precise, high-torque rotary positioning without the complexities associated with mechanical drives or hydraulic oil supplies. By eliminating the need for hydraulic pumps, hoses, and oil reservoirs, the EM-80/EM-300 systems significantly reduce environmental contamination risks and maintenance overhead while delivering superior control over fuel racks, fuel valves, and variable geometry turbochargers.

This comprehensive analysis details the technical specifications, operational principles, installation requirements, and maintenance protocols for the EM-80 and EM-300 actuator systems. Drawing from the official product specifications and installation manuals, this guide serves as an authoritative resource for engineers and technicians looking to implement or maintain these robust actuation solutions in demanding industrial environments.

System Architecture and Components

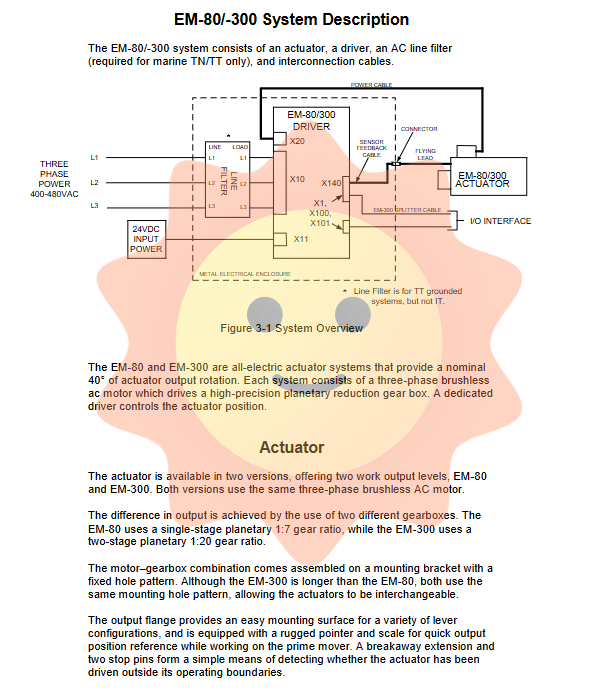

The EM-80/EM-300 system is not merely a motor; it is an integrated system comprising three primary components: the actuator assembly, the driver unit, and the interconnecting cabling.

1. The Actuator

The core of the system is a high-performance three-phase brushless AC motor coupled with a precision planetary reduction gearbox. This assembly is mounted on a robust bracket designed to absorb mechanical stress and ensure accurate positioning. Unlike traditional hydraulic actuators, the EM series provides a nominal 40 degrees of rotary travel, electronically limited to ensure the actuator does not exceed safe operating boundaries.

The actuator is available in two distinct variants: the EM-80 and the EM-300. While both share identical motor technology, they differ significantly in their gear reduction ratios, which dictates their torque output and slew rate characteristics.

EM-80: Utilizes a single-stage planetary gearbox with a 1:7 ratio. This configuration prioritizes speed and rapid response, making it ideal for applications requiring fast actuation times.

EM-300: Utilizes a two-stage planetary gearbox with a 1:20 ratio. This configuration trades speed for massive torque output, suitable for high-load applications such as large-bore engine fuel racks.

A critical design feature shared by both is the ISO 9409 output flange. This standardized interface allows for the easy mounting of levers and simplifies the replacement process, ensuring interchangeability between EM-80 and EM-300 units without the need to re-drill or modify the mounting surface.

2. The Driver

The EM driver serves as the “brain” of the system. It is a programmable digital controller housed in a separate enclosure designed for installation within a control cabinet, not on the engine itself. The driver’s primary function is to convert standard three-phase AC power (400–480 Vac, 50–60 Hz) into a controlled supply for the motor, managing current and potential across the three phases to precisely position the actuator shaft proportional to a 4–20 mA command signal.

The driver logic requires a separate 24 VDC power source for its internal electronics and I/O interfaces. This separation ensures that the control logic remains powered and capable of diagnostics even if the high-voltage power stage is disabled. The driver also manages the transition between peak torque output—available for the first second of movement—and steady-state torque, ensuring dynamic response without overheating the motor windings.

3. The Position Feedback System

Precise control relies heavily on accurate feedback. The system utilizes a hollow-shaft resolver mounted at the rear of the motor. This resolver provides sine and cosine wave outputs with an overall accuracy of 12 arc-minutes, delivering high-resolution position data to the driver.

However, the EM-80 and EM-300 differ slightly in their position-sensing architecture:

EM-80: The 1:7 gear ratio allows the output flange to achieve full 40-degree stroke in less than one full revolution of the motor shaft. Therefore, the resolver alone provides sufficient data to determine the exact position.

EM-300: The 1:20 gear ratio means the motor shaft rotates multiple times to achieve the full stroke. To ensure the driver knows which revolution the motor is in (and therefore the absolute position), a 10-turn potentiometer is added behind the resolver. This coarse signal allows the driver to deduce the correct rotor revolution, while the resolver provides fine accuracy within that revolution.

Detailed Actuator Specifications and Performance

Understanding the performance limits of the EM-80 and EM-300 is essential for correct application sizing.

Torque and Slew Rate

The primary distinction between the two models lies in their torque capabilities and speed of response (slew time).

EM-80 Specifications:

Nominal Torque (Continuous): 91 N·m (67 lb-ft) at up to 40°C ambient.

Maximum Torque (Transient): 190 N·m (140 lb-ft) for a maximum of 1 second.

Slew Time (10-90%): Approximately 78 ms with no load.

EM-300 Specifications:

Nominal Torque (Continuous): 260 N·m (192 lb-ft) at up to 40°C ambient.

Maximum Torque (Transient): 429 N·m (316 lb-ft) for a maximum of 1 second.

Slew Time (10-90%): Approximately 192 ms with no load.

Temperature Derating

A critical aspect of these actuators is their thermal management. While the units are rated for an ambient operating temperature range of 0 to +85°C, their continuous torque output is derated above 40°C.

EM-80: At 40°C, the unit produces 91 N·m. As the temperature rises to the maximum 85°C, the continuous torque capability drops to approximately 55 N·m.

EM-300: At 40°C, the unit produces 260 N·m. At 85°C, the capability drops to approximately 158 N·m.

Transient torque (peak torque) remains available across the entire temperature range, but operators must ensure that applications requiring high sustained torque do not exceed the derated limits, as this will lead to motor overheating, loss of torque, or driver shutdown.

Mechanical Interface and Installation

The physical installation of the EM-80/EM-300 requires careful attention to alignment and mounting surface integrity.

Weight: The EM-80 weighs approximately 35 kg (77 lb), while the EM-300 is slightly heavier at 38 kg (84 lb). Both are equipped with eyebolts for lifting.

Mounting Pattern: Both units use a similar mounting hole pattern. The distance from the front flange to the first row of holes is identical (68.0 mm), ensuring that an EM-80 can be replaced with an EM-300 without rearranging the linkage.

Flatness: The mounting surface must have a flatness of less than 0.2 mm (0.008”). Exceeding this tolerance can induce high stresses in the actuator and mounting bracket when fasteners are torqued.

Orientation: The actuator can be mounted at any angle of rotation about the motor shaft axis, provided the output flange is not more than 45 degrees above or below the opposite end of the actuator.

Stops and Safety

The EM-80 and EM-300 do not have internal mechanical stops. The stroke is electronically limited to 40 degrees. However, the system includes “soft stops” at 47.5 degrees. Inside this zone, the actuator can recover from a power failure and return to the correct working zone. If external forces drive the actuator beyond 47.5 degrees, the system may not be able to re-locate the proper working zone. While the actuator has a protective strip and stop pins to prevent accidental rotation, these stops cannot withstand the actuator’s peak torque.

For safety, it is recommended that external stops be designed into the fuel rack linkage to limit travel between the 40-degree operating range and the 47.5-degree safe range. These stops must be engineered to absorb the kinetic energy of the actuator mass and linkage (up to 15.1 Joules for EM-300).

Driver Installation and Electrical Connections

Proper installation of the driver is as critical as the actuator mounting. The driver must be installed in a metal electrical enclosure grounded (bonded) to earth.

Cabinet Requirements

The driver generates heat and requires adequate cooling.

Ventilation: Airflow must be from bottom to top.

Clearance: A minimum of 100 mm must be maintained above and below the unit, and 5 mm to the left and right.

Ambient Temperature: The driver is rated for 0 to 55°C. If the temperature at 50 mm below the device exceeds 45°C, the device power must be derated by 3% per °C.

Power Supplies

The system utilizes two distinct power inputs:

3-Phase Power (X10 Connector): 400–480 Vac, 50–60 Hz. This provides the muscle for the motor. It should be protected by fuses (e.g., class gG or slow-blow) or circuit breakers.

24 VDC Logic Power (X11 Connector): Required for the internal logic, I/O, and relays. This supply must be capable of 55 W and must be electrically isolated from the chassis for marine certification compliance.

Motor Connections (X20 Connector)

The driver connects to the actuator motor via the X20 connector.

Terminals U, V, W: Connect to the actuator motor phases.

PE: Protective Earth for the motor shield.

Cable Length: While 50 m is acceptable without additional equipment, up to 100 m is permissible provided a line reactor is used to manage cable parasitic capacitance.

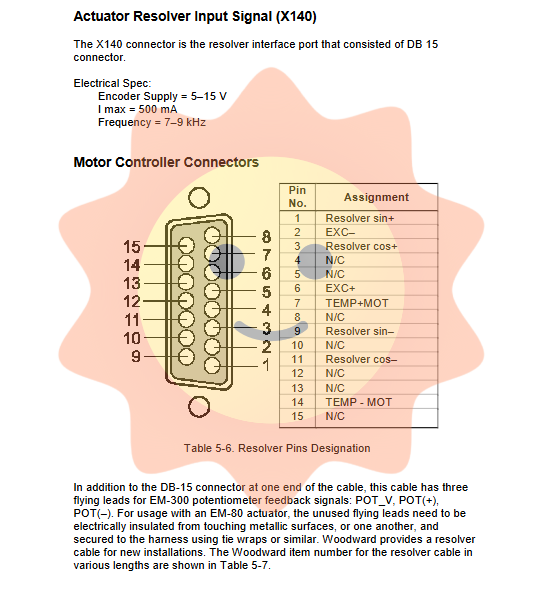

Resolver Connections (X140 Connector)

The resolver feedback uses a dedicated DB-15 connector. The cable includes flying leads for the EM-300 potentiometer (POT_V, POT+, POT-). For EM-80 applications, these unused leads must be insulated and secured. The resolver provides excitation and sin/cos feedback signals.

Pins: 1 (Sin+), 3 (Cos+), 6 (Exc+), 9 (Sin-), 11 (Cos-).

Temperature: Pins 7 and 14 carry the motor temperature sensor signal.

Control and I/O Interfaces (X100 & X101)

The driver interfaces with the external control system through several key signals:

Position Command (X100, Analog Input 1): Accepts a 4–20 mA input corresponding to 0–40 degrees. A 2 kΩ external shunt resistor is required across pins 1 and 3.

Actual Position Readout (X100, Analog Output 2): Provides a 1–5 V signal corresponding to the actuator’s actual position.

Ready for Use Output (X101): A discrete output (usually contact) indicating the system is fault-free and ready.

Common Alarm Output (X101): A discrete output that changes state on fault.

Pulse Enable (X1): An isolated digital input that must be “high” to enable the power stage.

E-Stop (X101): Configurable input (High or Low active) that drives the actuator to minimum position.

Reset (X101): A digital input to acknowledge and clear alarms.

Electromagnetic Compatibility (EMC) and Cabling

For a system operating with high-frequency switching electronics, EMC compliance is paramount to prevent interference with other shipboard or plant equipment.

Cabling Strategy

All system wiring must utilize shielded cabling.

Motor/Power Lines: These carry high interference potential. The shield must be grounded at both ends to the frame ground.

Resolver/Feedback Cables: These are sensitive. The shield must be grounded at both ends to prevent magnetic or high-frequency noise from affecting position data.

Signal Lines: 4–20 mA command and 1–5 V feedback cables must also be shielded.

Grounding Philosophy

The manual advises against classical “star” grounding for high-frequency noise reduction. Instead, a reference surface (e.g., a bare, metallic mounting plate) linked to the devices’ frame grounds over a wide area is preferred.

Connection Lengths: Ground conductors should be as short as possible (ideally < 30 cm).

Contact: Remove paint, varnish, or other insulating layers from grounding points. Use serrated lock washers to ensure permanent conductive contact.

Line Filter Considerations

An EMI filter (P/N 1326-1125) is required for marine systems using grounded power networks (TN or TT). However, it is NOT recommended for isolated power networks (IT) common in some marine or land-based applications. The filter’s internal RC networks can cause safety issues or nuisance faults when used with insulation monitors on IT systems.

System Configuration and Customization

The EM driver (specifically version 3522-1042) is field-configurable via the front keypad. This allows technicians to adapt the driver to specific application needs without special software tools.

Motor Type Selection (P11)

Because the driver supports both EM-80 and EM-300 actuators, the user must select the correct motor type via parameter P11 (0 for EM-80, 1 for EM-300). Failing to do so will result in incorrect torque limiting or fault codes (e.g., “Wrong Actuator” fault for EM-80 or “Pot Out of Range” for EM-300).

Rotation Sense (P10)

Parameter P10 allows the selection of clockwise (CW) or counter-clockwise (CCW) rotation to match the mechanical linkage setup.

E-Stop Logic (P14)

The behavior of the E-Stop input can be inverted. Setting P14 to 0 enables “E-Stop = LOW” (safe state), meaning a broken wire will drive the actuator to the minimum position. This is the recommended setting for safety.

Fault Behavior (P15 - Fault #64)

Fault #64 is triggered when the position demand signal falls below 3.6 mA. By default, this is a latching fault (the motor will not restart even if the signal returns).

Alarm Mode (P15=1): No reset required. If the signal returns, the motor moves.

Fault Mode (P15=3): Reset required.

Caution: In Alarm Mode, the actuator can move suddenly when the signal returns. Personnel must be clear of the linkage during such recovery sequences.

Troubleshooting and Maintenance

The EM-80/EM-300 system is designed to be largely maintenance-free. The gearbox is sealed and does not require oil changes unless operated continuously at the maximum temperature of 85°C, in which case oil replacement is advised at five-year intervals.

Electrical Troubleshooting

When diagnosing faults, specific resistance checks on the driver terminals can isolate the issue to the actuator, cable, or driver.

Motor Windings (Connector X20):

U to V, V to W, W to U should read approximately 0.5 Ω.

Resolver Connector (X140):

Pins 1 to 2 (Sin+ to Exc-): ~65 Ω

Pins 5 to 9 (Exc+ to Sin-): ~85 Ω

Pins 7 to 8 (Temp+ to Temp-): ~85 Ω

Potentiometer (EM-300 only, round connector on actuator):

Verify resistance at the mid-position (20 degrees). For example, at mid-stroke, resistance between specific pot pins should be around 5400 Ω. Significant deviation indicates a faulty potentiometer or wiring.

Common Fault Codes

The driver LCD provides alphanumeric fault codes to aid diagnostics:

Fault #31 (Short/Ground): Hardware short-circuit switch-off. Check motor windings and cable integrity.

Fault #33 (Overcurrent): Total motor current exceeded limits. Check for binding load or shorted motor phases.

Fault #37 (Encoder): Error due to encoder. Check resolver cable connections and shielding. EMI is a frequent cause.

Fault #41 (TempMotor TMS): Motor temperature sensor reports over-temperature. Check ambient temp and cooling; ensure load torque is within specs.

Fault #64 (Pos DMD lost): 4–20 mA input < 3.6 mA. Check control system output and wiring.

Fault #66 (3 Phase Off): Only applicable if redundancy is used; indicates loss of 3-phase power.

Power Redundancy (Appendix D)

For mission-critical applications, the EM driver supports a power redundancy scheme. If the primary 3-phase power fails, the system can switch to a single-phase backup power source (230 Vac) to maintain operation.

Sequence: 1. Loss of 3-phase (Alarm #66). 2. Switch to single-phase (within 140 ms). 3. Wait for voltage stabilization. 4. Restore 3-phase (within 40 ms of dropping single-phase).

This capability ensures the engine continues to run even during primary power anomalies.

Conclusion

The Woodward EM-80 and EM-300 actuator systems offer a sophisticated, high-performance solution for critical engine and turbine control. By leveraging advanced brushless motor technology and precision feedback mechanisms, they eliminate the environmental and maintenance drawbacks of hydraulic systems. Successful implementation, however, requires strict adherence to the detailed installation, cabling, and configuration guidelines outlined in the manuals. From the torque derating curves to the intricacies of EMC shielding, every parameter plays a role in ensuring the safety, reliability, and longevity of the actuation system. Whether used in marine propulsion or power generation, the EM-80/EM-300 stands as a testament to modern control engineering, providing the “muscle” needed for today’s most demanding prime movers.

Model Supplement

5464-414

9907-164

9907-252

5466-316

9907-167

9907-165

9907-149

9907-162

8444-1067

8446-1019

9907-1200

5501-470

5466-258

5501-467

5501-471

8237-1006

8701-758 5601-1126

8402-319 8402-119

8237-1600

9907-147

5233-2089

9907-1106

5453-203

5453-277

5466-318

5466-425

8440-1706 A SPM-D11

8440-1666 B

5437-1067A

5448-890 SPM-D10

5501-465

8901-457

8200-1302

BUM60-1224-54-B-001-VC-A0-0093-0013-G003-0000 3522-1004

8273-140

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA