Siemens MOBY I RFID System Configuration and Application Guide

Siemens MOBY I RFID System: A High Performance Non Contact Identification Solution for Industrial Automation

Introduction

In modern industrial production and logistics processes, reliable, fast, and non-contact identification and data tracking of objects have become key to improving efficiency and flexibility. The Siemens MOBY I wireless radio frequency identification (RFID) system is a high-performance solution designed for such high-end application scenarios. This system integrates features such as large capacity data storage, long-distance read and write capabilities, and high-speed data transmission, specifically designed to optimize material flow and production processes. This article will delve into the technical architecture, core components, configuration points, and installation guidelines of the MOBY I system, providing a complete set of application references for engineers and technicians.

System Overview and Technical Features

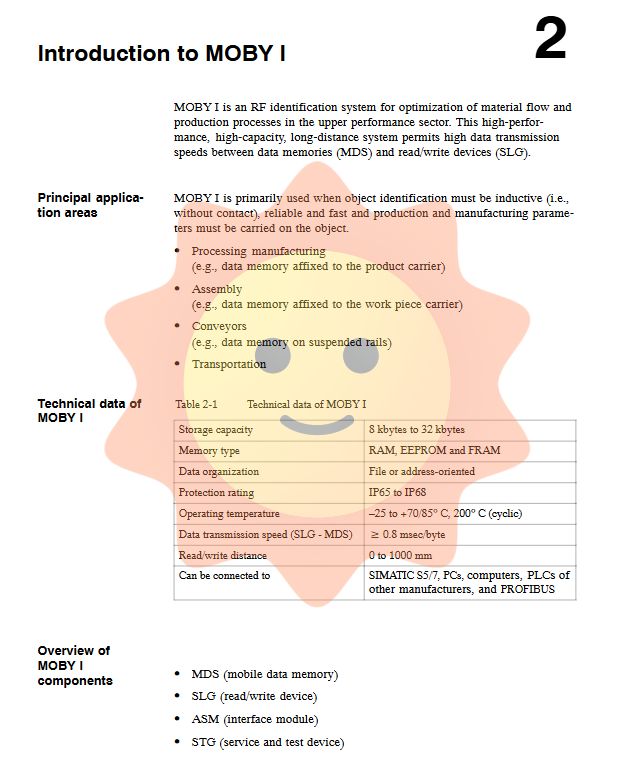

MOBY I is an identification system operating in the radio frequency (RF) band, with its core advantages being high capacity, long distance, and high transmission speed. The system has a storage capacity ranging from 8KB to 32KB, supporting multiple types of memory such as RAM, EEPROM, and FRAM. Data organization can be file oriented or address oriented. The read and write distance can reach up to 1000 millimeters (in conjunction with SLG 44 and MDS 507), with a data transmission rate of up to 19200 baud and a processing time of as short as 0.8 milliseconds per byte.

The system has a wide operating temperature range, and standard components can operate stably in environments ranging from -25 ° C to+70/85 ° C. The specially designed high-temperature resistant model MDS 439E can even withstand cyclic operating temperatures up to 200 ° C. All components have a protection level of IP65 to IP68, with excellent dust and water resistance, and can adapt to harsh industrial environments.

MOBY I has excellent compatibility and can seamlessly connect to Siemens SIMATIC S5/S7 series programmable logic controllers (PLCs), personal computers, other manufacturers' PLCs, and PROFIBUS fieldbus networks, making it easy to integrate into existing automation architectures.

Detailed explanation of core components

The MOBY I system consists of four core components: Mobile Data Storage (MDS), Read Write Device (SLG), Interface Module (ASM), and Service Test Device (STG).

Mobile Data Storage (MDS)

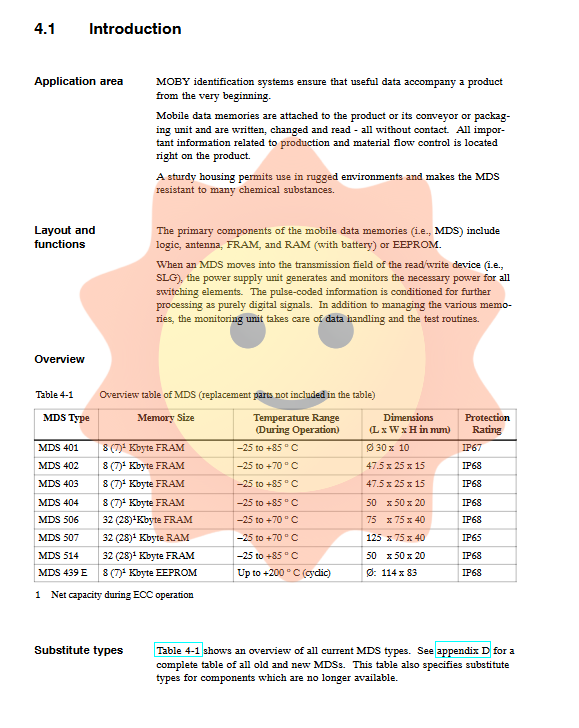

As a data carrier attached to carriers such as pallets and workpiece carriers, MDS is responsible for carrying and storing production data in the process. The system offers multiple models to meet different needs:

Compact: such as MDS 401 (Φ 30 mm) and MDS 402, using 8KB FRAM, suitable for short distance applications with limited space.

Universal type: such as MDS 403, 404, and 514, providing flexible installation methods and stable read-write performance.

Large capacity model: MDS 506 and 507 are equipped with 32KB memory (FRAM and RAM respectively), among which MDS 507 has a built-in dialogue battery and supports ultra long distance (up to 800mm) read and write with SLG 44.

High temperature resistant type: The MDS 439E adopts a polyphenylene sulfide (PPS) shell and 8KB EEPROM, designed specifically for high-temperature environments such as painting workshops and drying ovens, and can withstand cyclic high temperatures up to 220 ° C.

Read write device (SLG)

SLG is a fixed device that generates an induction field and exchanges data with MDS. Its models are distinguished based on read/write distance and field size:

Short distance: SLG 40/40-S, suitable for precise alignment of close range assembly lines.

Mid range: SLG 41 series (including SLG 41C/41CC) and SLG 42, providing balanced performance and size.

Long distance: SLG 43 has a large transmission window, suitable for large-sized MDS (such as MDS 506) and dynamic operations.

Ultra long distance: The SLG 44 is designed specifically to complement the MDS 507, achieving a hundred meter operating distance and suitable for high-speed or low precision positioning scenarios.

Interface Module (ASM)

ASM is a bridge that connects upper level control systems (such as PLC) with MOBY field components. Rich series, suitable for various control architectures:

SIMATIC S5 Integration: ASM 400/401 can be directly inserted into PLC racks such as S5-115U/135U/155U, and programmed using FB 250 (address access) or FB 230 (file processor) respectively.

Compact PLC: ASM 410 is suitable for small PLCs such as S5-90U/95U/100U and ET 100U, and can be directly controlled through process imaging.

PROFIBUS connection: ASM 450/452/454 supports the PROFIBUS DP/DPV1 protocol for easy distributed installation and integration. ASM 452 and 454 support non periodic communication with high data throughput.

SIMATIC S7 Integration: ASM 470/475 is designed specifically for S7-300/400 and ET 200M. ASM 470 uses FC 47, while ASM 475 serves as a parameterizable module that supports direct address access through FC 45 or file processor functionality through FC 56.

Serial interface: ASM 424 provides RS-232/422 interface and follows the 3964R protocol, making it easy to connect to PCs or third-party controllers.

Key technical points for system configuration and installation

The successful deployment of MOBY I system requires careful planning and configuration, and the following technical steps are crucial:

1. Calculation of transmission window and communication time

The effective area of the sensing field generated by the reading and writing device in space is called the "transmission window". Its shape is usually symmetrical about the SLG, containing two active regions with a possible signal gap in between (depending on the MDS model and direction). The key parameters include:

Operating distance (Sa): The range of reliable reading and writing distances.

Extreme distance (Sg): The farthest distance at which MDS can still be activated.

Window length (L) and width (B): determine the spatiotemporal window through which MDS can exchange data dynamically.

In dynamic operations, the transmission time (tF) must be greater than or equal to the communication time (tK). TV depends on the window length and MDS movement speed, while tK is determined by the system's internal time constant (K), transmission time per byte (t_byte), and data volume (n). Engineers must calculate the maximum amount of data that can be transmitted based on the production line speed, or determine the minimum allowable speed based on data volume requirements.

2. The impact and response of metal environment

Metal objects can significantly interfere with the induction field, leading to a reduction in transmission window size, shape distortion, or a shortened limit distance. During installation, it is necessary to follow:

Metal free space: Maintain a designated metal free area around MDS and SLG (size varies by model), especially during embedded installation.

Minimum spacing: Ensure the minimum distance between MDS and SLG to prevent inter field coupling interference.

Compensation measures: When it is impossible to avoid metal approaching, non-metallic gaskets can be used to increase spacing, rotate the SLG 90 ° to change the field direction, or increase the parasitic field of iron pillar short-circuit.

3. Electromagnetic Compatibility (EMC) Guidelines

To ensure stable operation of the system in an industrial electromagnetic environment, it is necessary to follow EMC guidelines:

Cabinet layout: Separate strong and weak electricity, lay signal and power lines in separate slots, and maintain a distance of at least 10 centimeters.

Shielding and grounding: All data cables must use a braided shielding layer and be extensively overlapped at both ends to the shielding and grounding bars. The metal components of the cabinet need to have good high-frequency conductive connections.

Equipotential connection: Use multi stranded wires with a cross-sectional area of not less than 10mm ² to connect the grounding points of each part of the system, reducing the balanced current caused by potential difference.

Interference source suppression: Install freewheeling diodes or RC circuits to suppress peak voltage on all inductive loads (contactors, relay coils).

Key configuration points for special models

MDS 507 and SLG 44: As MDS 507 relies on the built-in battery for operation, it is necessary to set the "ABTAST" parameter reasonably, that is, to cyclically query the time interval of signal existence, in order to avoid excessive discharge of the battery when the MDS stays near the SLG field for a long time. The transmission window has a complex shape, including both main and side lobes, and requires detailed field diagrams for configuration.

MDS 439E high temperature resistant type: When the internal temperature exceeds 85 ° C, its field length and limit distance will linearly decay with increasing temperature (offset coefficient C). In cyclic high-temperature applications, it is necessary to plan heating and cooling cycles to ensure that the internal chip temperature does not exceed the critical value of 110 ° C.

Cable connection and system integration

The MOBY connecting cable adopts a polyurethane (PUR) sheath, which is resistant to oil, acid, alkali, and hydraulic oil. A 6-core shielded cable is usually used between ASM and SLG (4-core for RS-422 data and 2-core for power supply). The maximum allowed cable length depends on the wire diameter and SLG current consumption (ranging from 70mA to 250mA), with a maximum length of up to 1000 meters. To achieve maximum distance, an auxiliary power supply can be installed near the SLG.

All prefabricated cables and plugs have clear order numbers. During installation, the cable shielding layer must be grounded with a large area, high frequency, and low impedance at both ends through shielding clamps or shielding bars. This is a key step in ensuring signal integrity and anti-interference ability.

Summary of Application Fields and Advantages

The Siemens MOBY I system, with its outstanding performance, is widely used in:

Processing and manufacturing: The data carrier is fixed on the product carrier to track production parameters.

Assembly line: fixed on the workpiece carrier, transmitting assembly instructions and status.

Conveyor system: installed on suspended tracks or trays to achieve routing control and sorting.

High temperature processes: such as painting, electrophoresis, and drying workshops in the automotive industry.

Its core advantage lies in integrating large capacity data storage, non-contact reliable read and write, high-speed dynamic processing capabilities, and robust environmental adaptability. Through modular components and flexible interfaces, MOBY I is able to provide tailored solutions for complex industrial automation and logistics tracking needs, making it a reliable infrastructure for achieving digital transformation and Industry 4.0 vision.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA