Comprehensive Analysis and Application Guide for SIEMENS S7-PLCSIM Advanced Simulation Software

Comprehensive Analysis and Application Guide for SIEMENS S7-PLCSIM Advanced Simulation Software

Siemens S7-PLCSIM Advanced is a powerful simulation software designed specifically for SIMATIC S7-1500 series programmable logic controllers. It allows users to comprehensively test and validate STEP 7 (TIA Portal) projects on virtual PLC instances without the need for real hardware. This software not only supports debugging of program logic, but also enables collaborative simulation with high-level language programs (such as C++/C #) or third-party simulation software (such as SIMIT, Simulink) through its application programming interface (API), providing an ideal platform for virtual debugging and operator training.

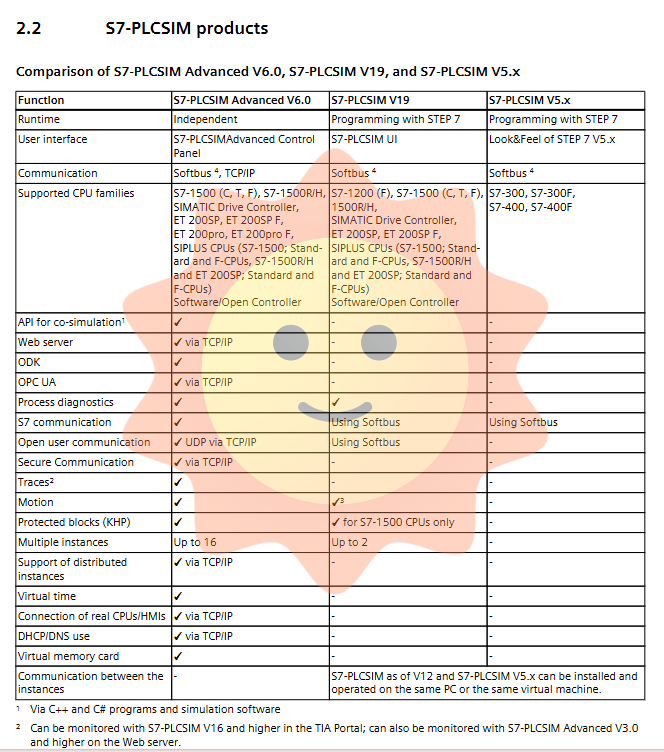

Core concepts and product positioning

The core of S7-PLCSIM Advanced is to create a highly realistic virtual PLC operating environment. It simulates the behavior of real S7-1500 CPUs (including standard, fail safe, compact, technical, redundant R/H, and SIMATIC Drive Controller). Users can download the hardware configured and user programs written in TIA Portal to this virtual instance for comprehensive functional testing, logic validation, and performance evaluation.

Compared to earlier versions such as S7-PLCSIM V5. x, the Advanced version has significantly enhanced features. It supports up to 16 simulation instances running simultaneously and provides complete Ethernet (TCP/IP) communication capabilities, allowing the simulated PLC to communicate with other simulation instances, real HMIs, and even real hardware CPUs on the same PC, across PCs, or even virtual machines. In addition, it also integrates simulation support for advanced features such as web servers, OPC UA servers, and secure communication (such as Secure Open User Communication).

Core application value and advantages

Using S7-PLCSIM Advanced for virtual engineering can bring multiple significant advantages to automation projects:

Improving quality and reducing costs: Program errors and design defects can be detected and corrected in the virtual environment in the early stages of the project, avoiding the risks and high costs that may arise from debugging on real hardware.

Shorten the time for market launch and debugging: Software testing and system validation can be carried out in parallel before the hardware is in place, greatly reducing the on-site debugging cycle.

Implementing virtual debugging and software in the loop testing: By connecting with machine or factory simulation models (collaborative simulation), the entire control system can be fully integrated and tested in the virtual world to verify process logic.

Safe operator training: Connect real or simulated HMI to provide systematic training for operators and maintenance personnel in a risk-free environment.

Improve flexibility and efficiency: facilitate pre validation for program optimization testing, equipment replacement, or factory expansion.

Key points for system installation and configuration

The installation of software has certain requirements for the system environment. It is recommended that each running simulation instance occupies at least one dedicated CPU core and requires 1GB of RAM. Supports Windows Professional and above operating systems, as well as mainstream virtualization platforms such as VMware and Hyper-V, but does not support Home Edition. Please note that some antivirus software or advanced threat prevention software may affect their performance or communication. It is recommended to add the relevant installation directory to the exception list.

Authorization uses floating licenses, where one license supports running two simulation instances in the same installation. The software provides a 21 day trial license. After installation, all instances are mainly managed and monitored through the "S7-PLCSIM Advanced Control Panel" control panel.

Communication Path: Bridge between Local and Distributed Simulation

S7-PLCSIM Advanced provides three main communication interface modes, which determine the reachable range of the simulation:

PLCSIM (Softbus): default mode. Communication through virtual software bus is limited to local computers or within virtual machines. This mode is the safest and can completely prevent programs from accidentally downloading to real hardware.

TCP/IP Single Adapter: Use a single Siemens PLCSIM virtual Ethernet adapter. This adapter can read all messages in the network, enabling distributed simulation across computers and virtual machines. Need to activate the 'S7-PLCSIM Advanced Virtual Switch' and associate it with a real physical network adapter.

TCP/IP Multiple Adapter: Suitable for environments where enterprise network security policies prohibit the use of promiscuous mode. It requires one-to-one MAC address mapping between the network interface of each simulated CPU and an independent physical or virtual network adapter on the PC.

Simulation implementation process

The basic process of conducting a simulation is clear:

Project preparation: In the properties of the TIA Portal project, the option "Support simulation during block compilation" must be checked. For blocks with proprietary technology protection, the option "SIMATIC S7-PLCSIM can be used for simulation" needs to be additionally enabled.

Create simulation instance: In the control panel, name the instance, select the PLC family (such as S7-1500), and start the instance.

Download project: In the download dialog box of TIA Portal, select the appropriate PG/PC interface (such as "PLCSIM" or "Siemens PLCSIM Virtual Ethernet Adapter") according to the communication mode, and download the hardware configuration and user program to the virtual PLC.

Operation and monitoring: Switching the virtual PLC to RUN mode allows for program debugging and diagnosis through TIA Portal's monitoring table, forced variables, and other functions, or through the control panel.

Advanced simulation function

Virtual time response: This is a unique feature of S7-PLCSIM Advanced. Users can enable 'virtual time' for simulation instances and accelerate or slow down the virtual clock by scaling factors (0.1 to 1000). This only affects time-based components (such as the call interval of loop OB) and does not affect code execution speed. This feature is very useful for testing time related logic or accelerating long-term process simulations.

ODK Function Simulation: Supports simulating custom function libraries for CPUs with Open Development Kit functionality (such as CPU 1518-4 PN/DP ODK). These function libraries written in C++run in separate "ODK client" Windows processes and are executed synchronously with STEP 7 user programs.

Motion Control Simulation: Supports basic motion control function simulation of S7-1500T technology CPU and SIMATIC Drive Controller. The logic of the technical object is simulated within the PLC, while the actual axis dynamics need to be simulated by connecting external simulation software through an API. Attention should be paid to the overflow detection of OB91 (MC Servo).

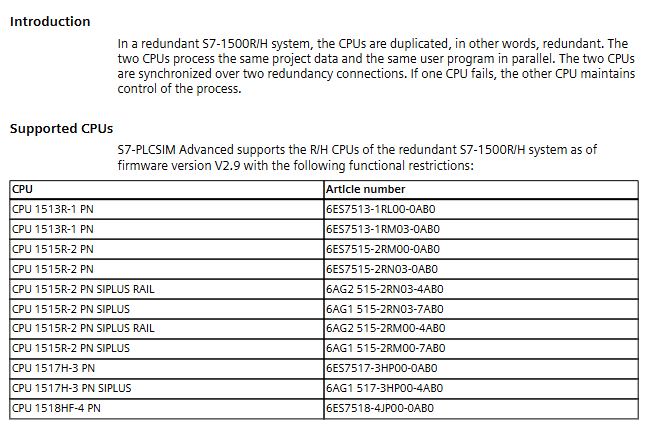

Redundant system simulation: Supports simulation of S7-1500R/H redundant CPUs, but is limited to the "RUN Solo" system state, which means a single CPU runs independently and cannot simulate the redundant synchronization and switching process between two CPUs.

Key Limitations and Precautions

Despite its powerful functionality, there are still differences between simulated environments and real hardware, and engineers must be aware of the following key limitations:

Non complete determinism: The simulation runs on a Windows system, and the precise timing of scanning cycles and actions may be affected by other processes on the PC, which may not be completely consistent with the behavior of physical hardware.

Hardware and bus limitations: Do not simulate fieldbus systems (such as PROFINET IO, PROFIBUS DP), real I/O modules, communication modules/processors, and CPU body I/O (only accessed as process images). I-Device functionality, copy protection, configuration control, and other functions are also not supported.

Some features have limited support: simulation of diagnostic buffer entries, some online diagnostic functions (such as firmware updates), and certain instructions (such as DP_TOPOL, T_CONFIG under Softbus) have limitations or are not supported.

Communication service limitation: When using Softbus, the TUSEND/TURCV (UDP) command will report an error and needs to switch to TCP/IP mode. MODBUS communication has specific requirements for library versions.

Security considerations: Simulation communication does not provide authentication and authorization protection by default. When communicating across computers, it is strongly recommended to use a closed simulation network that is isolated from the production network.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA