In depth analysis and selection guide for SIEMENS 3AH3 vacuum circuit breaker technology

SIEMENS 3AH3 Vacuum Circuit Breaker: A High Reliability Medium Voltage Switching Solution for Industrial and Generator Applications

In the field of medium and high voltage distribution and power generation, the reliability, breaking capacity, and full lifecycle cost of circuit breakers are the core considerations. The Siemens 3AH3 series vacuum circuit breaker, as a proven and mature product, has established its leading position in the global market with its unique vacuum arc extinguishing technology, modular design, up to 10000 maintenance free operation cycles, and special certification for harsh generator applications. This article is based on Siemens' official technical catalog (HG 11.03, 2018), and comprehensively analyzes the 3AH3 series from the aspects of technical principles, product series, special applications, and selection and configuration.

Core structure and technological advantages: vacuum arc extinguishing and maintenance free design

The core design concept of 3AH3 vacuum circuit breaker revolves around high reliability and maintenance free. Its structure mainly consists of two parts: pole assembly and operating mechanism box, connected by post insulators.

Arc extinguishing medium: vacuum arc extinguishing chamber

Adopting vacuum switch technology that has been developed for over 40 years as the arc extinguishing principle. The vacuum arc extinguishing chamber, with its excellent dielectric recovery characteristics, can quickly and reliably disconnect short-circuit currents ranging from small capacitive/inductive currents to up to 72kA. The air insulated and easily accessible design of the arc extinguishing chamber makes it possible to clean insulation components in harsh environments.

Operating mechanism: Spring energy storage type

The operating mechanism is of the spring energy storage type. The closing spring can store energy electrically or manually, and lock it as energy storage after the energy storage is completed. During the closing operation, the spring energy is released to drive the moving contact to close, while the spring energy is stored for the opening (or contact pressure) to prepare for the next opening. The mechanism has a free tripping function that complies with the IEC 62271-100 standard, ensuring that even if the closing command continues, the opening command can immediately open the circuit breaker.

The key to the commitment of "maintenance free"

Siemens claims that 3AH3 is maintenance free throughout its entire lifecycle, provided that it is used under normal environmental conditions as specified in IEC 62271-1 and the operating cycle does not exceed 10000 times. This is due to:

Durable mechanical design and long-lasting vacuum arc extinguishing chamber.

No need for recalibration or adjustment, its characteristic parameters are not affected by the opening and closing frequency or long-term static state.

Strictly follow IEC durability levels such as E2, M2, C2, S1, etc.

Product series and core electrical parameters: covering a wide range of application scenarios

The 3AH3 series offers multiple sub series, covering a wide range of needs from general industrial to specialized power generation.

Series classification Main standards Rated voltage range Rated current range Rated short-circuit breaking current Typical applications

3AH3 (high current type) IEC 62271-100 7.2 kV -40.5 kV 1250 A -6300 A 31.5 kA -72 kA Industrial distribution, motor drive, substation

3AH37/3AH38 (generator type) IEC 62271-100 and IEC/IEEE 62271-37-013 17.5 kV, 24 kV 3150 A-12000 A (forced air cooling) up to 90 kA thermal/hydraulic/nuclear power generator outlet protection

Core parameter analysis:

Rated current and ambient temperature: The standard rated current is based on an ambient temperature of+40 ° C. When the ambient temperature decreases, the circuit breaker can carry higher currents, and the product catalog provides detailed derating curves.

Insulation level and altitude correction: Standard insulation parameters (lightning impulse withstand voltage, power frequency withstand voltage) are applicable for altitudes below 1000 meters. Beyond this altitude, the air density decreases and the insulation strength decreases. It is necessary to increase the insulation level of the equipment according to the correction factor (Ks).

Capacitive current breaking capacity: All circuit breakers meet the C2 level requirements of IEC 62271-100 and have the ability to break line charging current, cable charging current, and back-to-back capacitor banks. For example, at 7.2kV, the line charging current breaking capacity can reach 10A.

Specialized solution: Generator circuit breaker and "phase isolation" design

Siemens has launched specially certified generator circuit breakers for the special and harsh working conditions of power plants.

Special standard: IEC/IEEE 62271-37-013

The generator circuit breaker not only needs to pass the conventional type test of IEC 62271-100, but also must meet the additional requirements of IEC/IEEE 62271-37-013 standard. This standard mainly considers:

Generator side fault: The extremely high DC component may cause the current to have no zero crossing point, posing a serious challenge to the breaking capacity of the circuit breaker.

System side fault: Higher transient recovery voltage (TRV) rise rate.

Higher test voltage level.

The 3AH37/38 series is designed to meet these harsh conditions, with a rated current of up to 8000A (natural cooling) or 12000A (forced cooling), and a short-circuit breaking current of up to 72-90kA.

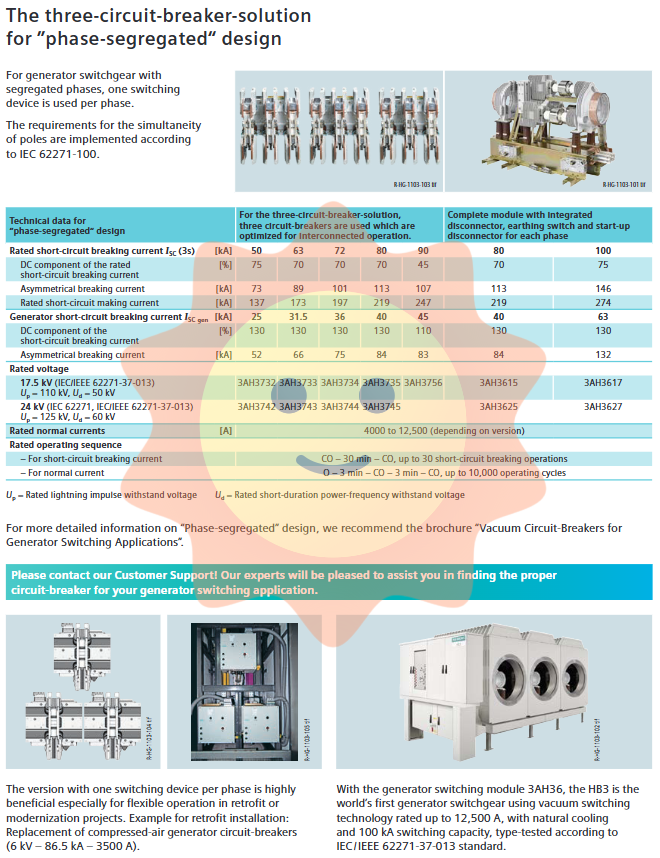

Revolutionary Architecture: "Phase Isolation" Three Circuit Breaker Solution

For large generators (especially those with a rated current exceeding 10kA), "phase isolated" switchgear is often used, which places the three phases in separate compartments. To this end, Siemens has launched an innovative three circuit breaker solution:

Use three independent 3AH36 generator circuit breaker modules, each controlling one phase.

Each phase module can integrate isolation switches, grounding switches, and starting isolation switches.

By optimizing parallel operation, this scheme can increase the breaking capacity to 100 kA and the rated current to 12500 A, providing a compact and efficient modern solution for replacing old and bulky compressed air generator circuit breakers.

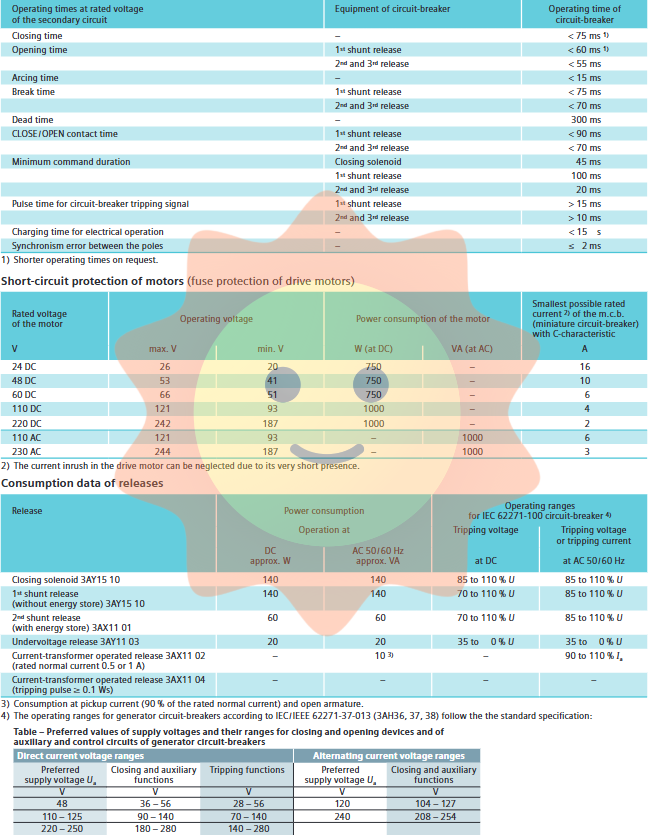

Secondary equipment and highly flexible selection and configuration

The strong flexibility of 3AH3 is largely reflected in its customizable secondary system.

Release combination

Circuit breakers can be equipped with multiple release devices to achieve different protection and control logics:

Closing coil: used for electric closing.

Split release: used to achieve remote automatic or manual disconnection through protective relays.

Undervoltage release: Automatically opens when the control voltage is lower than the set value.

Current transformer driven release: When there is no external auxiliary power source (such as battery), the protection relay obtains energy through CT to drive the disconnection.

Up to 3 release devices can be installed in combination, and users can choose different types of combinations according to their needs.

Auxiliary contacts and interfaces

The standard equipment provides 6 normally open and 6 normally closed auxiliary contacts, which can be upgraded to 12 normally open and 12 normally closed. The secondary interface provides multiple options such as 24 pole terminal blocks, 24 pole plugs, or 64 pole plugs to meet the needs of different wiring habits and automation systems.

Mechanical and electrical interlocking

It can be equipped with mechanical interlocking devices, which cooperate with the switchgear to reliably prevent the circuit breaker from being closed in non permissible states (such as when the handcart is not in place). It also supports electrical interlocking through auxiliary contacts and logical interlocking with devices such as isolation switches.

Detailed selection and ordering guide

Siemens provides a clear 16 digit order number structure to guide users through configuration.

Positions 1-8 (primary part): Define core electrical parameters such as rated voltage, insulation level, rated current, short-circuit breaking current, and inter electrode distance.

Positions 9-16 (secondary section): Define the type of release combination, operating voltage of each coil (optional from 24V DC to 240V AC), operating mechanism type, auxiliary contact configuration, plug type, document language, and power frequency.

Additional options and order codes: For special requirements such as anti condensation heaters, silicone free designs, higher insulation levels, gold-plated contacts, etc., they can be achieved by adding "- Z" and specific order codes after the order number.

The directory provides detailed configuration examples for various voltage levels from 7.2kV to 40.5kV, accompanied by configuration auxiliary brochures and online configuration tool links, making even complex configurations intuitive and convenient.

Technical data, attachments, and full lifecycle support

The latter half of the product catalog provides a complete technical data sheet, including precise dimensions, weight, operating cycle diagrams, and break times for each model.

Accessories and spare parts: A complete list of manual operating handles, lubricants, connector accessories, various coils and motors, spare vacuum arc extinguishing chambers, etc. is provided.

Full lifecycle support: Siemens emphasizes that when ordering spare parts, the equipment model, serial number, and manufacturing year must be provided to ensure a complete match of the spare parts. At the same time, the inquiry form at the end of the catalog provides a standardized template for customers to communicate with Siemens technical support teams.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA