Technical Analysis and Application Guide for Siemens EG Frame Molded Case Circuit Breaker NEB/HEB Series

Comprehensive Technical Analysis and Application Guide for Siemens EG Frame Molded Case Circuit Breaker NEB/HEB Series

Siemens, as a leading global enterprise in the field of electrical engineering, is renowned for its molded case circuit breaker products with high reliability, modular design, and wide applicability. This article will focus on the NEB and HEB series molded case circuit breakers under the Siemens EG framework, and provide a detailed analysis of product structure, electrical performance, installation configuration, and accessory systems based on official technical data. The aim is to provide a complete, professional, and practical technical reference for electrical designers, system integrators, and maintenance personnel.

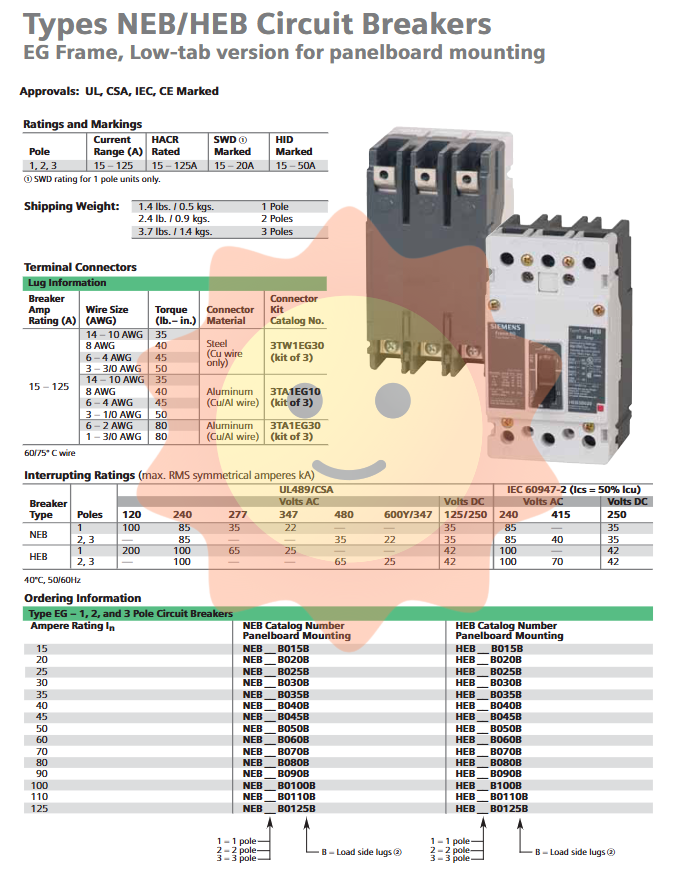

Product Overview and Basic Specifications

The EG frame circuit breaker is a series of molded case circuit breakers developed by Siemens for low to medium current distribution needs. It is suitable for panel mounting, with a compact structure and easy integration. This series offers 1-pole, 2-pole, and 3-pole models to meet the protection needs of different distribution systems.

Weight and Structure:

The weight of a 1-pole circuit breaker is approximately 1.4 pounds (0.5 kilograms), 2-pole is 2.4 pounds (0.9 kilograms), and 3-pole is 3.7 pounds (1.4 kilograms). Lightweight design facilitates installation and handling while maintaining structural strength.

Certification and Standards:

This series of products has passed multiple international certifications, including UL, CSA, IEC, and CE marks, meeting the safety and performance requirements of major global markets and suitable for industrial, commercial, and residential power distribution systems.

Current range and rating:

The rated current range is 15A to 125A, with HACR (Heating, Ventilation, and Air Conditioning Equipment Rating) certification, suitable for motor load protection. In addition, some models are labeled with SWD (switch discrete capacity) rating (only for single pole models) and HID (high-intensity discharge lamps) protection rating, expanding their application in lighting and control circuits.

Wiring terminals and electrical connections

Reliable electrical connections are the foundation of circuit breaker performance. The EG series provides flexible terminal block options and supports the connection of copper wire and copper aluminum mixed cables:

Circuit breaker rated current (A) wire size (AWG) torque (lb. - in.) connector material connector kit catalog number

15-125 14-10 35 steel (copper wire only) 3TW1EG30 (3-piece set)

8 6-4 45 aluminum (copper/aluminum wire) 3TA1EG10 (3-piece set)

3-3/0 14-10 35 Aluminum (Copper/Aluminum Wire) 3TA1EG30 (3-Piece Set)

6-2 80 Aluminum (Copper/Aluminum Wire) 3TA1EG30 (3-Piece Set)

Steel connectors are suitable for pure copper wires, while aluminum connectors are compatible with both copper and aluminum wires, enhancing installation flexibility. Clearly indicate the torque value to ensure connection reliability and long-term stability.

Breaking ability and electrical performance

The breaking capacity is a key indicator for measuring the safe interruption of current by a circuit breaker under fault conditions. The NEB and HEB series perform excellently under different voltage systems:

Series pole number UL489/CSA breaking capacity (kA) IEC 60947-2 (Ics=50% Icu)

NEB 1 85 @ 120V, 35 @ 240V, 22 @ 277V, 35 @ 480V 85 @ 240V AC, 22 @ 415V AC

2,3 85 @ 240V, 35 @ 480V, 22 @ 600V 85 @ 415V AC, 40 @ 600V AC

HEB 1 100 @ 120V, 65 @ 240V, 25 @ 277V, 42 @ 480V 100 @ 240V AC, 42 @ 415V AC

2,3 100 @ 240V, 65 @ 480V, 42 @ 600V 100 @ 415V AC, 70 @ 600V AC

NEB series: suitable for general distribution protection, with moderate breaking capacity and high cost-effectiveness.

HEB series: With stronger breaking capacity, it is suitable for occasions with higher requirements for short-circuit protection, such as transformer secondary side, busbar protection, etc.

All tests are based on 40 ° C ambient temperature and 50/60Hz power supply conditions, which are in line with the actual application environment.

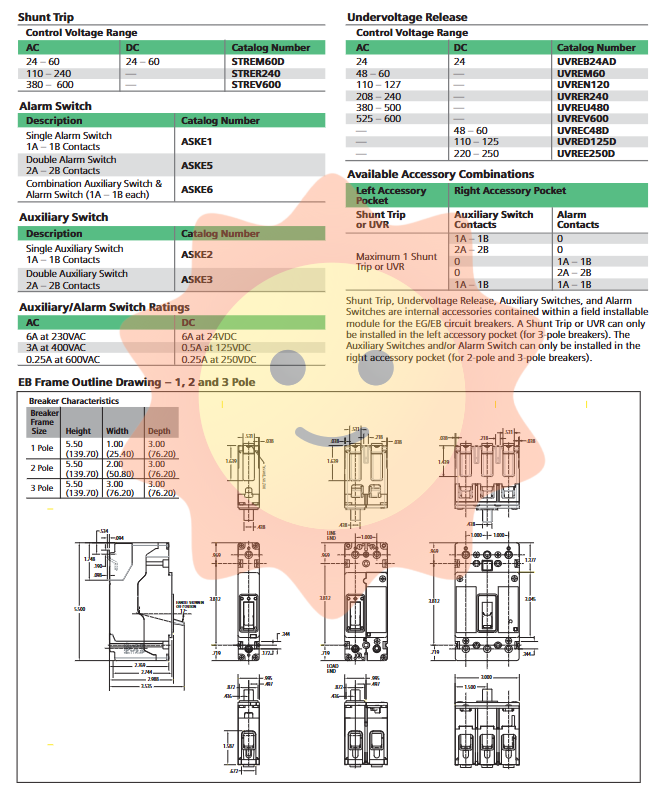

Accessory System and Function Expansion

The EG framework circuit breaker supports a wide range of built-in accessories and can be expanded through on-site module installation without the need to replace the circuit breaker body

1. Split Trip

Used for remote trip circuit breakers, suitable for emergency shutdown or automation control:

Control voltage range (AC) Control voltage range (DC)

24 – 60V 24 – 60V

110 – 240V —

380 – 600V —

2. Alarm Switch

Provide circuit breaker status signals, suitable for monitoring systems:

Single alarm switch (1A – 1B contacts): catalog number ASKE1

Dual alarm switch (2A-2B contacts): catalog number ASKE5

Combination auxiliary and alarm switch: catalog number ASKE6

3. Auxiliary Switch

Used to indicate the status of circuit breaker contacts, suitable for interlocking and control circuits:

Single auxiliary switch (1A – 1B contacts): catalog number ASKE2

Dual auxiliary switch (2A-2B contacts): catalog number ASKE3

4. Undervoltage Release

When the system voltage is lower than the set value, it automatically trips to protect the equipment from damage caused by low voltage operation:

AC control voltage range DC control voltage range

24V 24V

48 – 60V —

110 – 127V —

208 – 240V —

380 – 500V —

525 – 600V —

— 48 – 60V

— 110 – 125V

— 220 – 250V

5. Rules and combinations for accessory installation

Left accessory slot: Only shunt release or undervoltage release can be installed (applicable to 3-pole circuit breakers).

Right accessory slot: Only auxiliary switches and/or alarm switches can be installed (applicable to 2-pole and 3-pole circuit breakers).

Maximum configuration example:

Left side: 1 shunt release or undervoltage release

Right side: Up to 2 sets of auxiliary contacts (2A – 2B) or 1 set of alarm contacts (1A – 1B)

Installation and System Integration Guide

The EG frame circuit breaker adopts a low plug version design, optimized for panel board installation, with a compact structure and space saving. Attention should be paid during installation:

Thermal compatibility and environmental adaptability: All electrical parameters are based on a 40 ° C environment, and capacity reduction needs to be considered in high-temperature environments.

Wiring specifications: Strictly tighten the wiring terminals according to torque requirements, use designated connector kits to avoid overheating caused by poor contact.

Installation sequence of accessories: First install the left release accessories, then install the right signal accessories to ensure accurate module docking.

System coordination: In selective protection systems, coordination settings should be made based on the breaking capacity and time current characteristics of the upper and lower circuit breakers.

Application scenarios and selection suggestions

Commercial building power distribution: The NEB series is suitable for protecting lighting, sockets, and air conditioning circuits.

Industrial control system: HEB series is suitable for motor control center and distribution cabinet incoming line protection.

Key power system: equipped with shunt release, undervoltage release, and alarm switch to achieve remote monitoring and fault protection.

Renewable energy system: suitable for DC side protection of photovoltaic distribution boxes and energy storage systems (pay attention to DC voltage rating).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA