SIEMENS SIMATIC RF120C Communication Module Comprehensive Analysis and Application Guide

Siemens SIMATIC RF120C Communication Module Comprehensive Analysis and Application Guide

Introduction

RFID technology plays an increasingly important role in industrial automation and logistics identification systems. The Siemens SIMATIC RF120C communication module serves as a dedicated extension module for the SIMATIC S7-1200 controller, enabling efficient integration and data exchange of RFID readers. This article is based on official operating instructions and systematically reviews the technical characteristics, installation configuration, parameter settings, programming methods, and maintenance diagnosis of RF120C, providing a complete technical reference for project implementation and system maintenance.

Product Overview and Functional Features

1.1 Application Fields

The SIMATIC RF120C communication module is designed specifically for the SIMATIC S7-1200 controller and is suitable for various industrial identification scenarios, such as material tracking, warehouse management, production line control, etc. The module supports connecting a single RFID reader or optical reader through the RS422 interface and is compatible with the following device series:

RF200, RF300, RF600 (including RF620R/RF630R)

MV400/MV500 optical reader

MOBY D/U recognition system

1.2 Core Functions

Physical addressing support: Supports direct physical addressing of the responder, also known as standard addressing.

Multi module expansion: A S7-1200 controller can run up to three RF120C modules simultaneously.

Integrated configuration: Implement hardware configuration and parameter allocation through TIA Portal, without the need to separately configure reader parameters in the program.

Protection level: IP20, suitable for installation inside control cabinets.

Standard cable support: Provides pre installed cables of 2m, 5m, 10m, etc. to simplify on-site wiring.

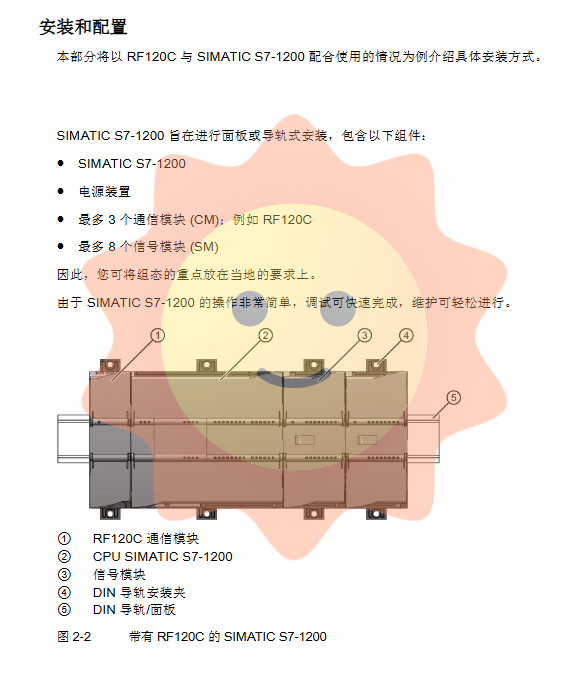

Installation and hardware connection

2.1 Installation prerequisites

Only qualified professionals are allowed to operate, ensuring compliance with safety regulations.

The equipment must operate at Safety Extra Low Voltage (SELV) and the power supply must comply with IEC 60950-1 standard.

2.2 Installation steps

Disconnect the power and remove the bus cover on the left side of the CPU.

Align RF120C with the CPU bus connector and insert it until the buckle is locked.

Install the assembled module onto a 35mm DIN rail.

Connect the 24V DC external power supply to the top 3-pin terminal (L+, M, ground) of the module.

Use a D-type connecting cable (9-pin) to connect the reader to RF120C.

Connect the power, close the module front cover, and complete the hardware installation.

2.3 Electrical Connection Instructions

Power input: 24V DC, maximum current 1A, used to power the reader.

Communication interface: 9-pin D-type socket, supporting RS422 communication, with a maximum cable length of up to 1000m (depending on the reader type).

Backplane bus power supply: The module itself is powered through the S7-1200 backplane bus, without the need for external auxiliary power supply.

Software configuration and parameter settings

3.1 Integrated Development Environment

Since STEP 7 Basic/Professional V13, RF120C has been integrated into TIA Portal. Users can complete the configuration through the following steps:

Add S7-1200 devices to the TIA Portal project.

Select "Communication Module>Identification System>RF120C" from the hardware directory and drag it into the device view.

Set parameters in the module properties and download them to the controller.

3.2 Key parameter group

(1) Reader parameter group

Diagnostic message: The error reporting mechanism can be defined by selecting levels such as "none" and "hard error".

User mode: Usually select 'Ident profile' to use standard function blocks.

Ident device/system: Select based on the actual connected reader type, such as RF300 regular, RF600, MOBY U, etc.

(2) Ident device/system parameter group

Transfer speed: Supports 19.2 kBd, 57.6 kBd, 115.2 kBd, and needs to be consistent with the reader settings.

RF power: Adjustable reader transmission power (e.g. RF380R supports 0.50-2.00W).

Existence check: Control whether to monitor the real-time entry of the transponder into the antenna field.

Distance limit: Set the effective recognition distance of the reader (0.2-3.5m).

BERO mode: used for sensor synchronous control of antenna field switches.

(3) Reader type parameter group (RF600 series only)

Wireless configuration files: ETSI, FCC, or CMIIT.

Multi label mode: supports UID as EPC-ID or Handle-ID.

Transmission power adjustment: The antenna output can be precisely controlled through hexadecimal values.

Programming and Addressing of Answerers

4.1 Function Block Support

RF120C provides a complete Ident function block library, including:

Read、Write

Read_EPC-ID、Write_EPC-ID

Set_Sent (antenna control)

Reset-Reader (Reader Reset)

AdvancedCmd (Advanced Command)

These blocks are called through Ident configuration files and support cyclic and non cyclic data exchange.

4.2 Detailed explanation of addressing for sending responders

RF120C supports linear addressing, and the address range varies depending on the type of responder being sent

(1) ISO 15693 labels (such as RF200, MOBY D)

MDS D139:44 bytes, addresses 0x0000-0x002B

ISO-MDS (Tag It HF-1): 256 bytes, addresses 0x0000-0x00FF

Identification area: Fixed address 0xFFFF, length 8 bytes, read-only.

(2) RF300 series labels

EEPROM user memory: can be used as read/write (R/W) or write once (OTP) storage.

OTP area: Address 0xFF80-0xFF93, cannot be changed after writing, suitable for permanent data such as serial number and production date.

(3) RF600 series (compliant with EPC Gen2 standard)

User memory: The length varies depending on the chip model, such as 96 bits for Impinj Monza 2 and up to 480 bits for Alien Higgs 3.

System area: includes protection functions such as EPC, TID, reserved password, and deactivated password (KILL-PW).

(4) MOBY U series

Data storage: 2KB or 32KB, with addresses starting from 0x0000.

OTP memory: 16 bytes, address 0xFFFF, only allows one-time writing.

Diagnosis, Error Handling, and Maintenance

5.1 LED status indication

RF120C provides multi-level LED status display:

Front panel DIAG LED: green constant light (normal), green flashing (started/not configured), red flashing (error), red constant light (fault needs to be replaced).

Internal LED group (need to open the cover to view):

DC 24V (green): External power supply is normal

PRE (green): The responder is present

Rx (yellow): In data communication

ERROR (flashing red): The specific error code can be identified through the flashing pattern

5.2 Error Message Analysis

Detailed error information can be obtained through the STATUS output parameter of the function block, with the following structure:

Byte 0: Error category (e.g. E1: Label related; E4: Hardware malfunction)

Byte 1: Error number (0x80-0x8F indicates controller parameter error)

Byte 2: Specific error code

Byte 3: Warning message (RF120C has no warning function)

Typical error examples:

E1 FE 01: Writing to tag memory failed (possibly due to memory lock or depleted lifespan)

E4 FE 01:24V output short circuit or overload

E5 FE 08: Command buffer full, waiting or initialization required

5.3 Module replacement and reset

The configuration data of RF120C is stored in the CPU, and after replacing the module, the CPU automatically retransmits the parameters. If communication abnormalities occur, the following operations can be performed:

Power off and restart the module.

Call the Reset-Reader function block.

Check the power supply and cable connections.

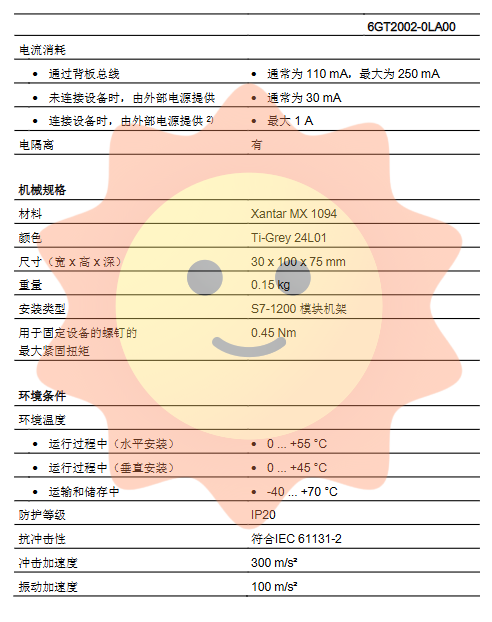

Technical data and certification

6.1 Main specifications

Power supply: 24V DC (20-30V range), backplane bus power consumption ≤ 250mA, maximum external output 1A

Communication speed: up to 115.2 kbps (RS422)

Working temperature: 0-55 ° C for horizontal installation, 0-45 ° C for vertical installation

Protection level: IP20

Size: 30 × 100 × 75mm (width × height × depth)

6.2 Certification and Standards

CE: Compliant with EMC Directive 2014/30/EU and RoHS Directive 2011/65/EU

Explosion proof certification: ATEX (II 3G Ex nA IIC T4 Gc), IECEx (Ex nA IIC T4 Gc)

Industrial standards: EN 61000-6-2/4, EN 55011, UL 508, cULus Listed

MTBF: Approximately 196 years at 40 ° C environment

Cable and accessory selection

7.1 Standard Cable

Connection cable (RF120C to reader): 2m/5m/10m optional (order number such as 6GT2091-4LH20)

Extension cable (M12 to M12): up to 50m, suitable for long-distance deployment

MOBY dedicated cable: suitable for D/U series label systems

7.2 Suggestions for self-assembled cables

If standard cables are not applicable, a 7 × 0.25mm ² shielded cable (LiYC11Y type) can be used in conjunction with a D-type or M12 connector to be self-made. Pin definitions can be found on page 20 of the document.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA