SIEMENS SIPROTEC 4 System: A Comprehensive Solution for Power Protection and Automation

SIPROTEC 4: Integrated Future of Power System Protection, Control, and Automation

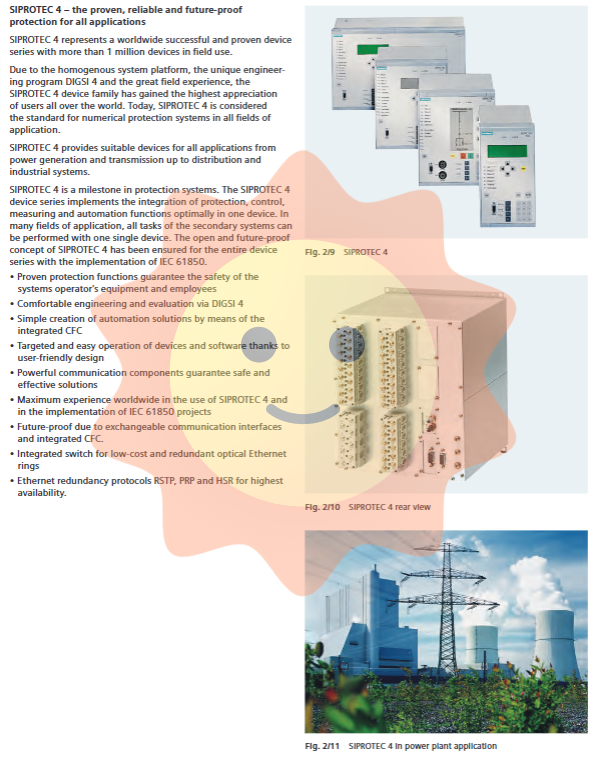

In modern power systems, ensuring the continuity, safety, and stability of power supply is the core task. With the increasingly complex structure of the power grid, the large-scale integration of renewable energy, and the increasing demand for power quality from users, traditional single function protection equipment is no longer able to meet the requirements of efficient, flexible, and reliable operation. The SIPROTEC 4 series equipment launched by Siemens is a comprehensive solution designed to address these challenges. It is not just a set of protective relays, but also an intelligent platform that integrates protection, control, measurement, and automation functions, representing the development direction of secondary equipment in medium and high voltage power systems.

Overview and Design Concept of SIPROTEC 4 System

The SIPROTEC 4 series is a mature product line from Siemens that has undergone decades of on-site validation and has over a million devices in operation experience. The core of its design lies in "integration" and "openness". It breaks the traditional situation where protection, measurement and control, and automation equipment operate independently, and achieves deep integration of multiple functions through a single hardware platform. The concept of "one device per interval" greatly simplifies the system structure, reduces cabinet space, external wiring, and engineering debugging costs, while improving the overall reliability of the system.

This series is based on a unified hardware platform and powerful DIGSI 4 engineering software, providing users with a high degree of configuration flexibility. The device supports standard rack sizes ranging from 1/3 to 1/2 19 inches and is compatible with replacing old and new systems. Its hardware design is sturdy and durable, ensuring stable operation in harsh industrial environments through rigorous electromagnetic compatibility, insulation, mechanical, and climate stress testing. The back of the device provides modular communication interfaces that can be selected or upgraded according to on-site needs. It supports various mainstream industrial protocols including IEC 61850, IEC 60870-5-103, PROFIBUS DP, MODBUS, DNP 3.0, PROFINET, etc., reflecting the principle of openness towards the future.

Deep analysis of core technology characteristics and functions

Comprehensive protection function library: SIPROTEC 4 is equipped with extremely rich protection functions, covering almost all the protection needs of power main equipment and systems.

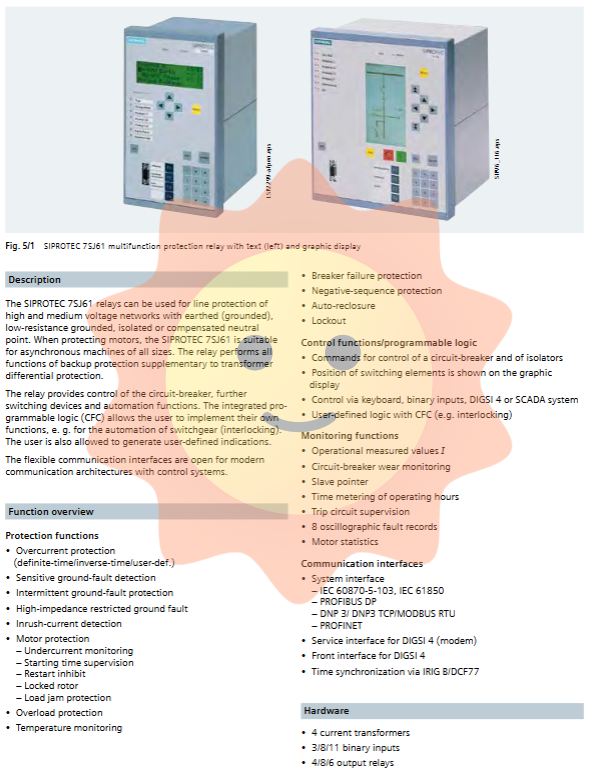

Line protection: Provides non directional/directional overcurrent protection (50/51, 67), ground fault protection (including sensitive directional ground fault detection 67Ns), distance protection (21, implemented through models such as 7SA6), line differential protection (87L, implemented through models such as 7SD5 series), and automatic reclosing (79).

Transformer protection: In addition to serving as a backup protection for transformer differential protection (87T, such as 7UT6 series) (providing overcurrent, overload, ground fault, etc.), it also has a high impedance lockout type ground fault protection (87N) function, which is used to quickly cut off ground faults in transformer windings.

Generator and motor protection: Provides a complete unit protection scheme, including differential protection, stator grounding protection, negative sequence protection (46), demagnetization protection, overvoltage/undervoltage protection, overclocking/low-frequency protection, starting time monitoring (48), thermal overload protection (49), locked rotor protection, etc., suitable for rotating motors from small to large.

Busbar protection: Supports simple busbar protection through overcurrent relays, and also provides distributed digital busbar protection based on differential principles (such as 7SS52), with circuit breaker failure protection function.

System protection: including low-frequency and low-voltage load shedding (27, 81), frequency change rate protection (81R), power direction protection (32), reverse power protection, etc., used to maintain system stability.

Adaptive and intelligent protection: SIPROTEC 4 introduces the concept of "adaptive relay protection". The device is equipped with up to 4 switchable parameter setting groups, which can automatically switch the set value group through binary input or communication instructions according to changes in the operation mode of the power grid (such as transformer switching, connection line opening and closing loop, cold load starting, etc.), optimizing protection performance. In addition, the "flexible protection function" allows users to configure any measured or derived quantity (such as df/dt, dV/dt, power direction) as standard protection logic, easily creating up to 20 user-defined protection stages and achieving highly customized protection strategies.

Integrated control and automation: Equipment is not only a protective unit, but also a powerful interval layer controller. It supports direct control of primary equipment such as circuit breakers, isolating switches, and grounding switches, and has a complete command processing sequence, interlocking logic, position monitoring, and operation permission management (local/remote/DIGSI). Through the integrated CFC graphical logic editor, users do not need programming knowledge and can design complex automation sequences and station interlocks by simply dragging and dropping logic components (AND, OR, NOT, timers, triggers), achieving deep collaboration between protection and control.

Advanced monitoring and diagnosis: SIPROTEC 4 provides monitoring capabilities far beyond traditional equipment. In addition to conventional measurements of three-phase current, voltage, power, frequency, and electrical energy, it can also calculate and display sequence components, harmonic content, power factor, etc. The device continuously performs hardware and software self checks, including CT/PT circuits, trip circuits, power batteries, etc. The detailed fault recording function (supporting COMTRADE format), event sequence recording with time stamps, circuit breaker action statistics, and contact wear evaluation provide a solid data foundation for rapid fault analysis, status maintenance, and asset optimization management.

Future oriented communication and system integration capabilities

Communication capability is one of the core advantages of SIPROTEC 4. Its modular design allows for flexible configuration of communication interfaces, ensuring seamless integration of devices into any automation system.

IEC 61850 Core Support: Siemens is one of the first manufacturers in the world to support the IEC 61850 standard. SIPROTEC 4 fully supports this standard and enables Ethernet based communication at the station and process layers. Through GOOSE services, critical data such as tripping and interlocking signals can be quickly and reliably transmitted point-to-point between devices, achieving distributed intelligence. SV service supports process bus applications. MMS services are used for efficient data model interaction with monitoring systems.

Multi protocol compatibility: In addition to IEC 61850, the device also supports multiple traditional and industrial protocols, such as IEC 60870-5-103, PROFIBUS DP, MODBUS RTU/TCP, DNP 3.0 Serial/TCP, and PROFINET IO. This multi protocol coexistence capability protects users' existing investments and facilitates gradual upgrades in renovation projects.

High availability network: Supports Ethernet redundancy protocols such as RSTP, PRP, and HSR, and can use integrated switches in communication modules to build low-cost dual ring networks, significantly improving the reliability and availability of communication networks.

Engineering and maintenance interface: The RS232 interface and optional independent service interface on the front panel facilitate local or remote parameter tuning, fault data analysis, equipment debugging, and diagnosis through DIGSI 4 software, greatly simplifying operation and maintenance work.

Powerful engineering and support software ecosystem

The success of SIPROTEC 4 is inseparable from its powerful software toolchain support.

DIGSI 4: This is a unified engineering platform for configuring, managing, and maintaining all SIPROTEC 4 and Compact devices. Its interface is intuitive and supports parameter settings with primary or secondary values. The core "routing matrix" function can graphically configure the association of all I/O, LED, and signals. The integrated CFC editor makes logic programming simple and intuitive. DIGSI 4 also supports remote access through modems or networks, enabling efficient centralized management and rapid fault response.

IEC 61850 System Configurator: As a part or standalone tool of DIGSI, it supports system level engineering of IEC 61850 equipment for the entire substation based on SCL files, including network topology definition, data set and report control block configuration, GOOSE connection establishment, etc. It is the key to achieving interoperability among multiple vendor devices.

SIGRA 4: Professional fault recording and analysis software. It can not only display fault data in various ways such as time curves, vector graphs, impedance graphs, etc., but also automatically calculate derivative quantities, synchronize multi terminal waveform recording, perform offline distance measurement, and generate professional analysis reports, making it a powerful assistant for system fault analysis.

Typical applications and selection guidance

The document provides a detailed list of typical protection configuration schemes for various main connections, from simple radial feeders to complex double busbar one and a half circuit breaker connections, from distribution transformers to large generator sets. For example:

For dual ended power supply lines, the main protection can use fiber optic current differential protection (7SD5/61), while the backup protection adopts distance protection (7SA6) and directional overcurrent protection, forming a dual configuration with different principles and mutual redundancy.

For important transformers, the main protection adopts digital proportional differential protection (7UT6), while the backup protection can be provided by 7SJ62/64 for complete overcurrent, grounding, and non electric quantity protection.

In the distribution network, 7SJ61/62, in conjunction with automatic reclosing function, can effectively handle transient faults and coordinate with downstream fuses or reclosers.

When selecting, it is necessary to comprehensively consider the protected object (line, transformer, motor, etc.), voltage level, main wiring form, requirements for protection speed/selectivity/sensitivity, whether direction judgment is needed, whether integrated control function is needed, and the communication protocol requirements of the upper system.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA