Analysis and Application of Siemens SMART LINE V5 HMI Technology

Visualization and Objects: Added GIF player to make interface animations more vivid. The system function library has been expanded, enhancing the control ability of visual objects.

Data management: The functions of formula, data recording, trend curve, table view, etc. have been comprehensively enhanced. For example, supporting up to 50 recipes, each recipe can contain up to 100 data records. The variable archiving and alarm archiving functions provide powerful tools for production process analysis and fault tracing.

Overview of System Performance and Capacity Parameters

WinCC flexible SMART V3 sets clear and sufficient performance boundaries for project development. The following is a summary of the capability limitations of its core objects:

Project structure: Supports up to 150 images and 1000 variables. 50 UDTs can be created and instantiated 50 times to meet the needs of medium-sized projects.

Alarm system: supports 32 alarm categories, 400 discrete alarms, 20 analog alarms, and is equipped with a 512 capacity power-off hold alarm buffer.

Data recording: 2 logs can be configured, with each log recording 40 variables and supporting segmented loop recording.

Script: Up to 100 scripts can be created, with a total size limit of 5MB, leaving space for complex logic.

IoT connectivity: Supports 1 MQTT/SIMICAS connection, which can transmit up to 100 variables through SIMICAS or 300 variables through generic MQTT.

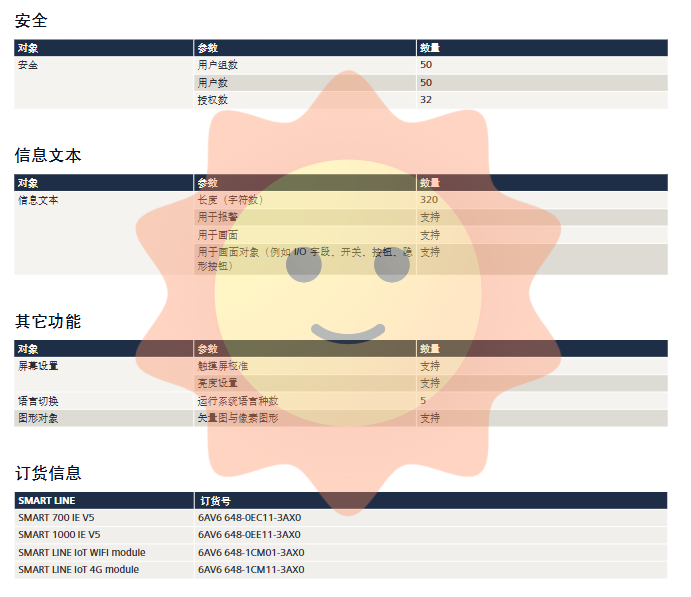

Security and Multilingualism: Supports up to 50 users and 50 user groups, with 32 different permissions. The operating system supports switching between 5 languages.

These parameters define a powerful and clearly defined visual development platform that is capable of meeting the HMI requirements of the vast majority of OEM equipment and small production lines.

Summary of Application Scenarios and Value

The release of SMART LINE V5 precisely aligns with the current trend of manufacturing towards flexibility, digitization, and remote development. Its typical application scenarios include:

Single machine equipment: As the control and monitoring core of independent equipment such as textile machinery, packaging machinery, and plastic processing machinery, it provides a user-friendly interface and equipment status visualization.

Small production line: connected to S7-200 SMART PLC to achieve multi station collaborative control, production data statistics, and alarm management.

Remote operation and maintenance scenario: By selecting IoT modules, equipment manufacturers can provide remote diagnosis, parameter optimization, and preventive maintenance services for devices distributed throughout the country and even globally, building new service models and revenue growth points.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA