Analysis and Application of Siemens SMART LINE V5 HMI Technology

Siemens SMART LINE V5: Reshaping a New Standard for Small Automation Human Computer Interaction

In the field of industrial automation, human-machine interface (HMI) serves as an important bridge connecting operators and control systems, and its performance and functionality directly affect production efficiency and operation experience. Siemens has officially launched the new generation of SIMATIC's exciting panel series, SMART LINE V5, targeting the vast Chinese and global OEM markets. This upgrade is not a simple iteration, but a comprehensive and strategic enhancement of hardware performance, software ecology, and connectivity capabilities based on the high compatibility advantages of the previous V4 version. It aims to collaborate with the S7-200 SMART PLC to build a more flexible, efficient, reliable, and cost competitive small automation solution cornerstone.

Product positioning and core upgrade: compatibility and evolution simultaneously

The first release of the SMART LINE V5 series includes two models: SMART 700 IE V5 (7-inch widescreen) and SMART 1000 IE V5 (10.1-inch widescreen). One of its most popular features in the market is that the opening size is completely consistent with the V4 version. This means that existing users using V4 panels do not need to change the mechanical design of the control cabinet when upgrading, greatly reducing upgrade costs and engineering complexity, and protecting users' existing investments.

While maintaining physical compatibility, V5 version has achieved comprehensive evolution internally:

At the hardware level, it has been upgraded to a high-performance ARM dual core 1.2GHz CPU and equipped with 256MB DDR3 memory, providing ample computing power for more complex graphics logic, data processing, and emerging functions such as script execution. The project memory reaches 20MB, supporting larger and richer engineering configurations.

Interface Expansion: Added RS232 serial interface, coexisting with the existing RS422/485 interface, greatly enhancing the flexibility of connecting with various serial devices such as printers, scanners, and specific instruments. The newly added Micro SD card slot (supporting speeds up to 25 MB/s) makes data recording, project backup, and firmware upgrades more convenient. The power-off holding time of RTC clock has been extended to 3 years, reducing maintenance requirements.

Empowering the Internet of Things: This is the most forward-looking upgrade of the V5 series. The panel supports expanding IoT modules, and users can choose WIFI module (CM01) or 4G module (CM11) according to their needs. By connecting to Siemens cloud platform SIMICAS, secure VPN remote access, HMI variable remote monitoring and debugging can be achieved, significantly reducing engineers' travel costs and on-site maintenance time, and helping enterprises achieve digital operation and maintenance, cost reduction and efficiency improvement.

In depth analysis of hardware technical specifications

Both panels use TFT-LCD display screens, supporting 16.77 million colors, with a brightness of 350 cd/m ², and a backlight half brightness lifespan of 20000 hours, ensuring clear visibility in various lighting environments. The touch screen is analog resistive, stable and reliable.

The comparison of core hardware parameters is as follows:

Equipment SMART 700 IE V5 SMART 1000 IE V5

Display size: 7-inch widescreen, 10.1-inch widescreen

Resolution 800 x 480 pixels 1024 x 600 pixels

Hole size (W × H) 192 x 138 mm 259 x 201 mm

Installation method supports horizontal/vertical installation

Power supply 24 V DC (19.2-28.8V) 24 V DC (19.2-28.8V)

Communication interface 1x RJ45 Ethernet (10/100 Mb/s), 1x USB 2.0, RS422/485, RS232, Micro SD same as left

Protection level: front panel IP65, back panel IP20 same as left

Certification CE, UKCA, RoHS are the same as the left

Key data of IoT module:

Power consumption: 5V DC power supply, maximum current consumption of 600mA.

Connection capability: WIFI module supports 2.4GHz/5GHz dual band; The 4G module supports mainstream LTE frequency bands in China.

Data function: Supports remote transmission of up to 100 real-time variables and 30 historical variables, with historical data storage lasting up to 2 years.

The leap in software functionality and configuration capabilities

The configuration software of SMART LINE V5 has been synchronously upgraded to WinCC flexible SMART V5. This software is fully compatible with and can import V4 version project files, ensuring smooth and worry free project migration. Its enhanced functionality is reflected in multiple dimensions:

Connectivity and Protocol: In addition to deep optimization and integration with S7-200 SMART (supporting encrypted communication), we will continue to support LOGO! Mainstream PLCs such as Mitsubishi FX series (Protocol 4), Modicon Modbus, Omron CP/CJ series, etc. The addition of support for Freeport protocol based on serial port provides maximum flexibility for connecting non-standard devices.

Programming and Data Types: Introducing scripting functionality, supporting the use of JavaScript as a scripting language, allowing users to write custom logic and achieve more complex control and computation. The addition of support for user-defined data types (UDT) greatly improves the efficiency of complex data management and the degree of project structuring.

Visualization and Objects: Added GIF player to make interface animations more vivid. The system function library has been expanded, enhancing the control ability of visual objects.

Data management: The functions of formula, data recording, trend curve, table view, etc. have been comprehensively enhanced. For example, supporting up to 50 recipes, each recipe can contain up to 100 data records. The variable archiving and alarm archiving functions provide powerful tools for production process analysis and fault tracing.

Overview of System Performance and Capacity Parameters

WinCC flexible SMART V3 sets clear and sufficient performance boundaries for project development. The following is a summary of the capability limitations of its core objects:

Project structure: Supports up to 150 images and 1000 variables. 50 UDTs can be created and instantiated 50 times to meet the needs of medium-sized projects.

Alarm system: supports 32 alarm categories, 400 discrete alarms, 20 analog alarms, and is equipped with a 512 capacity power-off hold alarm buffer.

Data recording: 2 logs can be configured, with each log recording 40 variables and supporting segmented loop recording.

Script: Up to 100 scripts can be created, with a total size limit of 5MB, leaving space for complex logic.

IoT connectivity: Supports 1 MQTT/SIMICAS connection, which can transmit up to 100 variables through SIMICAS or 300 variables through generic MQTT.

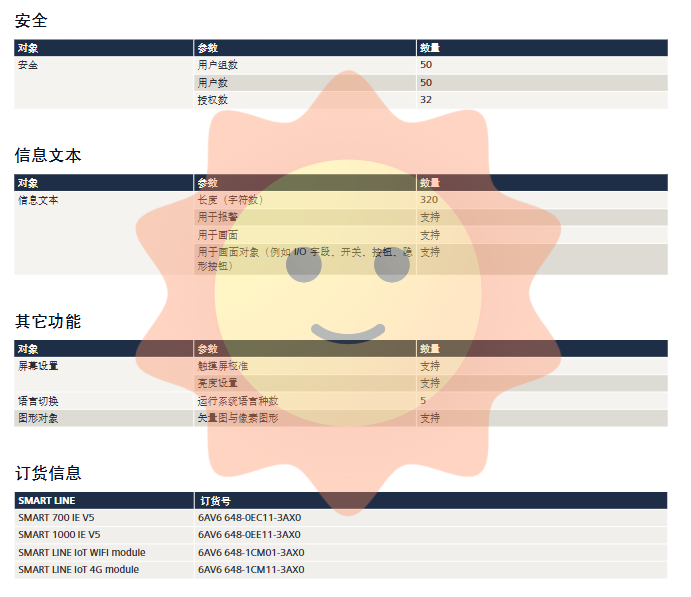

Security and Multilingualism: Supports up to 50 users and 50 user groups, with 32 different permissions. The operating system supports switching between 5 languages.

These parameters define a powerful and clearly defined visual development platform that is capable of meeting the HMI requirements of the vast majority of OEM equipment and small production lines.

Summary of Application Scenarios and Value

The release of SMART LINE V5 precisely aligns with the current trend of manufacturing towards flexibility, digitization, and remote development. Its typical application scenarios include:

Single machine equipment: As the control and monitoring core of independent equipment such as textile machinery, packaging machinery, and plastic processing machinery, it provides a user-friendly interface and equipment status visualization.

Small production line: connected to S7-200 SMART PLC to achieve multi station collaborative control, production data statistics, and alarm management.

Remote operation and maintenance scenario: By selecting IoT modules, equipment manufacturers can provide remote diagnosis, parameter optimization, and preventive maintenance services for devices distributed throughout the country and even globally, building new service models and revenue growth points.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA