Woodward EM-80/EM-300 Electric Actuator Specification Guide

Compliance with major maritime classification societies (ABS, BV, LR, RMRS) and rigorous environmental testing (shock, vibration, humidity) makes these actuators suitable for the harshest environments found on ships and offshore platforms. The elimination of hydraulic oil not only simplifies the maintenance schedule but also eliminates a significant environmental hazard. Whether applied to a large diesel generator set or a steam turbine governor, the EM-80/EM-300 series stands as a cost-effective, high-performance solution for modern rotary actuation needs.

Comprehensive Technical Specification and Application Guide for Woodward EM-80/EM-300 Electric Actuator Systems

Executive Summary

In the evolving landscape of industrial power generation and propulsion, the shift from hydraulic and mechanical actuation to high-performance electric actuation is driven by the need for precision, reduced environmental impact, and lower maintenance overhead. The Woodward EM-80 and EM-300 all-electric actuator systems represent the pinnacle of this technology, designed to deliver precision, high-torque rotary positioning without relying on mechanical drives or hydraulic oil supplies. These systems are specifically engineered for controlling engine fuel racks in large diesel and gas engines, though their versatility allows for application on various turbine types for controlling fuel valves, variable geometry turbochargers, and handling timing control.

This guide provides an in-depth analysis of the product specifications for the EM-80/EM-300 MDS 5150A/LIT Actuator System. It details the operational characteristics, mechanical constraints, and environmental ratings that engineers must consider when integrating these actuators into critical control loops. By understanding the nuances of the EM-80 versus the EM-300 models, system integrators can optimize for either rapid response (slew rate) or high torque output depending on the specific demands of the prime mover.

System Architecture and Core Components

The EM-80/EM-300 system is defined by its integration of three core technologies: a high-performance motor, a precision reduction gearbox, and a dedicated driver unit. The architecture is designed to eliminate the “compliance” and “maintenance issues” often associated with hydraulic linkages while providing a stiffer, more responsive control interface.

1. The Electric Motor

At the heart of the system lies a three-phase brushless AC motor. Unlike brushed motors, the brushless design eliminates physical wear associated with carbon brushes, significantly extending service life and reducing maintenance intervals. The motor provides the rotational energy that is necessary to drive the load, characterized by high efficiency and the ability to maintain performance across a range of operating temperatures. The brushless nature also contributes to the overall cleanliness of the system, avoiding the carbon dust and arc-associated degradation found in brushed alternatives.

2. Precision Planetary Gearbox

To translate the high-speed, low-torque rotation of the motor into the high-torque, low-speed rotation required at the fuel rack, the system employs a high-precision planetary reduction gear box. This gearbox is selected for its high stiffness and low backlash characteristics. High stiffness is critical in governor applications; it ensures that the actuator responds immediately to the driver’s command without elastic deformation that could lead to oscillation or “hunting” in the engine’s RPM. Low backlash is equally important, as it provides a deadband-free response, ensuring that small control signals from the governor result in immediate physical movement of the fuel rack.

3. The Driver Unit

The EM driver acts as the central control unit, housing both the power board and the controller logic within a single enclosure. This digital controller is fully programmable, allowing it to accommodate custom application requirements. The driver manages the current supplied to the motor, effectively controlling the torque output and position with high fidelity. It serves as the interface between the external control system (typically an Engine Control Unit or Governor) and the physical actuator.

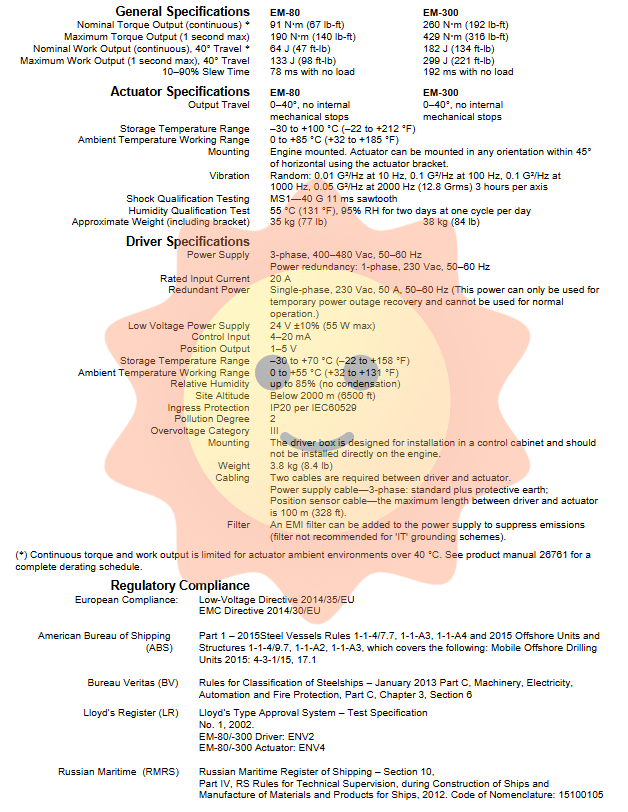

Detailed Product Specifications

Understanding the quantitative capabilities of the EM-80 and EM-300 is essential for selecting the correct unit for a given application. The specifications are split between General Specs, Actuator Specs, and Driver Specs.

General Specifications: EM-80 vs. EM-300

The primary distinction between the two models lies in the trade-off between speed and torque.

1. Nominal Torque Output (Continuous)

Torque is the rotational force applied by the actuator. For continuous operation (sustained load holding or movement over time), the EM-80 is rated for 91 N·m (67 lb-ft), while the larger EM-300 provides significantly higher output at 260 N·m (192 lb-ft).

*Implication:* The EM-300 is suited for engines with stiff fuel linkages or high-friction racks where substantial force is required to move the rack, whereas the EM-80 is sufficient for smaller bore engines or systems with lighter loads.

2. Maximum Torque Output (1 second max)

This rating defines the peak force available for short durations, typically used during rapid acceleration of the rack. The EM-80 can deliver 190 N·m (140 lb-ft) for a maximum of one second. The EM-300 provides a massive peak of 429 N·m (316 lb-ft).

*Implication:* The 1-second rating allows the actuator to overcome stiction or static friction during startup. The EM-300’s high peak torque is crucial for breaking away stiff fuel linkages in cold conditions.

3. Work Output (Energy)

Work is defined as torque over a specific distance (rotation).

Nominal Work Output (Continuous, 40° Travel): EM-80 is 64 J (47 ft-lb); EM-300 is 182 J (134 ft-lb).

Maximum Work Output (1 second max, 40° Travel): EM-80 is 133 J (98 ft-lb); EM-300 is 299 J (221 ft-lb).

*Implication:* The work output rating helps engineers calculate the energy capacity of the actuator, ensuring the system can perform the required mechanical work (moving the fuel rack from idle to full power) without overheating during the stroke.

4. 10–90% Slew Time

Slew time is the speed at which the actuator can rotate, measuring the time taken to move from the 10% position to the 90% position.

EM-80: 78 ms with no load.

EM-300: 192 ms with no load.

*Implication:* The EM-80 is a “fast” actuator. Its sub-100ms slew time makes it ideal for applications requiring rapid governing to maintain frequency stability or transient response. The EM-300 is slower but compensates with its higher torque. This highlights the classic engineering trade-off: the EM-80 trades torque for speed, while the EM-300 trades speed for torque.

Actuator Mechanical Specifications

The physical characteristics of the actuator dictate how it integrates with the engine mounting structure.

1. Output Travel

Both the EM-80 and EM-300 provide a fixed rotation range of 0–40 degrees. Crucially, there are no internal mechanical stops. This design choice places the responsibility on the external mechanical linkage (engine fuel rack) to define the hard stops. This prevents the actuator from driving itself against an internal wall, which could damage the gearbox, but requires the installer to ensure the external linkage has adequate travel limits.

2. Temperature Ratings

Storage Temperature Range: –30 to +100 °C (–22 to +212 °F). This wide range ensures the units can be shipped and stored in extreme environments without degradation.

Ambient Temperature Working Range: 0 to +85 °C (+32 to +185 °F). This robust operating range allows installation on engines in hot engine rooms or in climates where ambient heat is significant.

3. Mounting and Orientation

The actuators are designed to be engine-mounted. They can be mounted in any orientation provided they are within 45° of horizontal using the actuator bracket. The included bracket design ensures that stresses in the actuator are minimized by providing a rigid, pre-drilled interface. The specifications note that actuator performance is based on installation that includes this bracket; using alternative mounting methods may alter stress profiles and affect durability.

4. Shock and Vibration

Given the harsh environment of diesel engines, vibration and shock resistance are paramount.

Vibration Qualification: Random vibration profile: 0.01 G²/Hz at 10 Hz, rising to 0.1 G²/Hz at 100 Hz, sustained at 0.1 G²/Hz at 1000 Hz, and tapering to 0.05 G²/Hz at 2000 Hz. The test is performed at 12.8 Grms (Root Mean Square) for 3 hours per axis. This rigorous testing ensures the actuator’s internal electronics and mechanical components remain intact despite the constant shaking of a running engine.

Shock Qualification Testing: MS1–40 G 11 ms sawtooth. This simulates sudden impacts, such as a rough sea state for marine engines or a sudden emergency shutdown event.

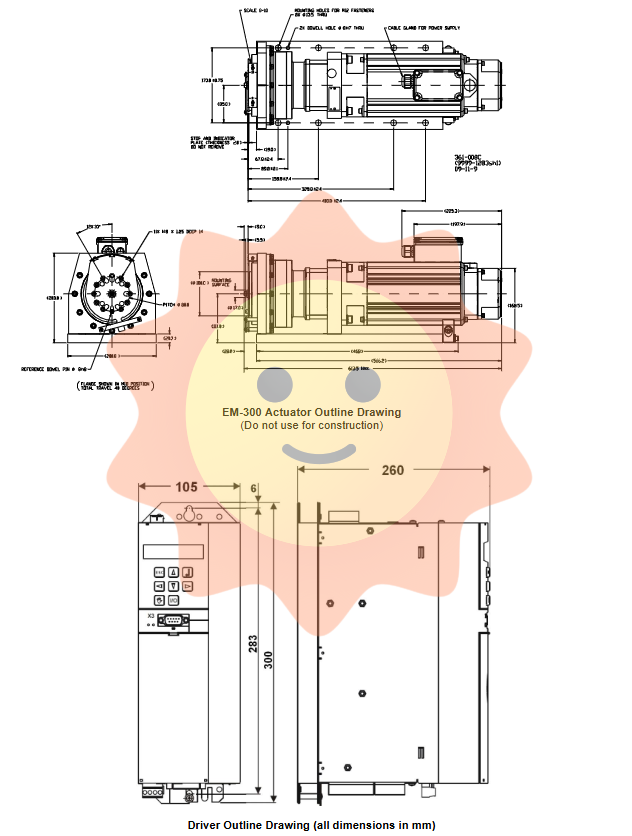

5. Weight and Dimensions

EM-80 Weight: Approximately 35 kg (77 lb) including the bracket.

EM-300 Weight: Approximately 38 kg (84 lb) including the bracket.

The small weight difference suggests the majority of the mass is in the motor and housing, with the gear ratio change in the EM-300 adding minimal mass but significant mechanical advantage.

6. Humidity

The system is qualified to withstand 55 °C (131 °F) at 95% Relative Humidity for two days, undergoing one cycle per day. This ensures moisture ingress will not cause corrosion of the internal electronics or mechanical seizure.

Driver Unit Specifications

The driver unit, separate from the actuator, houses the power electronics and logic.

1. Power Supply

Main Power: The driver requires a 3-phase, 400–480 Vac, 50–60 Hz power source. This industrial standard voltage is typically available in plant and marine environments.

Redundant Power: The system supports a power redundancy feature utilizing 1-phase, 230 Vac, 50–60 Hz. It is critical to note that this redundant power is rated for 50 A, but can *only* be used for temporary power outage recovery and cannot be used for normal operation. This feature allows the engine to maintain control during a brief loss of the main 3-phase supply, preventing an immediate engine trip.

2. Rated Input Current

The driver draws a significant current to maintain actuator performance:

Normal Operation: 20 A.

Redundant Mode: 50 A on the single-phase backup line. The higher amperage in single-phase mode reflects the need to draw equivalent power from a reduced number of phases.

3. Low Voltage Power Supply

The logic and control circuits operate on a 24 V ±10% supply, with a maximum power rating of 55 W. This separates the sensitive logic from the high-voltage motor drive, enhancing reliability and safety.

4. Environmental Ratings (Driver)

Storage Temperature: –30 to +70 °C (–22 to +158 °F).

Ambient Temperature Working Range: 0 to +55 °C (+32 to +131 °F).

Ingress Protection: IP20 per IEC60529. This rating means the driver is protected against solid objects greater than 12.5mm (fingers) and water dripping vertically. This dictates that the driver must be installed in a clean, dry control cabinet, not on the engine itself.

Pollution Degree: 2 (Non-conductive pollution; dry, non-conductive dust).

Overvoltage Category: III (Equipment in fixed installations).

5. Cabling

Two distinct cables are required between the driver and the actuator:

Power Supply Cable: A standard 3-phase cable including a protective earth conductor.

Position Sensor Cable: This cable carries the resolver feedback. The maximum allowable length is 100 m (328 ft). This generous length allows the driver to be located remotely in a switchgear room while the actuator is mounted on the engine.

6. Filter (EMI)

An Electromagnetic Interference (EMI) filter can be added to the power supply to suppress emissions. However, the specifications explicitly state this filter is not recommended for ‘IT’ grounding schemes. IT (Isolated Terra) systems are common in some marine and industrial setups where the neutral is not earthed; using an EMI filter in these configurations can create a ground fault path or reduce safety.

7. Regulatory Compliance and Certifications

The EM-80/EM-300 system carries extensive certifications allowing for global deployment.

European Compliance:

Low-Voltage Directive 2014/35/EU: Ensures safety from electrical hazards.

EMC Directive 2014/30/EU: Ensures the system does not emit excessive electromagnetic interference and is immune to it.

Marine Type Approvals (Crucial for shipping):

American Bureau of Shipping (ABS): Compliant with Part 1 – 2015 Steel Vessel Rules, specifically sections 1-1-4/7.7, 1-1-A3, and 1-1-A4. Also covers Mobile Offshore Drilling Units 2015.

Bureau Veritas (BV): Compliant with Rules for Classification of Steelships (Jan 2013), Part C, Chapter 3, Section 6.

Lloyd’s Register (LR): Type Approval System – Test Specification No. 1, 2002.

Russian Maritime Register of Shipping (RMRS): Section 10, Part IV, RS Rules for Technical Supervision, Code of Nomenclature: 15100105.

Specific Environment Ratings: The Driver is rated ENV2, and the Actuator is rated ENV4. These environment classifications typically denote the specific operating conditions (e.g., engine room vs. open deck) recognized by the classification society.

Key Features and Application Benefits

The Woodward EM-80/EM-300 series offers several distinct features that enhance usability and safety.

1. ISO 9409 Flange

The actuator output utilizes an industry-standard ISO 9409 flange. This standardized interface allows for easy mounting of levers and simplifies replacement. If an actuator fails, the ISO flange allows a technician to swap the unit without needing to machine custom adapters. Furthermore, the orientation of the output flange relative to the bracket base is identical for both EM-80 and EM-300 units. This interchangeability is a major advantage for inventory management; a shipyard or plant can keep one common interface design and swap between high-torque (EM-300) and high-speed (EM-80) units based on engine requirements.

2. Breakaway Stops

The actuators are equipped with breakaway stops designed to prevent the actuator from exceeding its maximum output travel range during setup. These stops are mechanical safety features intended to protect the internal gearbox during the installation and commissioning phase. They are not designed to withstand full operating torque during engine operation, which reinforces the need for proper external stop setting on the fuel rack.

3. Output Position Indicator

An output position indicator is standard equipment. This provides a visual, local indication of the actuator’s position, essential for technicians during manual testing or commissioning when the driver electronics may not be active or accessible.

4. Single Driver Compatibility

A single EM-driver is used for both EM-80 and EM-300. The software setup is the only variable. This reduces spare parts complexity. The driver is capable of auto-detecting or being configured for the specific inertia and torque characteristics of the attached motor/gearbox combination.

5. Monitoring and Diagnostics

Integrated monitoring allows the system to track most features of the actuator, including temperature, position error, and electrical faults. This diagnostic capability is vital for predictive maintenance, allowing operators to detect issues like winding shorts or resolver faults before they lead to catastrophic engine failure.

Conclusion

The Woodward EM-80/EM-300 MDS 5150A/LIT Actuator System provides a robust, all-electric solution for the control of large prime movers. By offering two distinct models, Woodward caters to the diverse needs of the industry: the EM-80 for applications demanding high-speed response and the EM-300 for those requiring high torque output. Both systems share a common architecture of a brushless AC motor, precision planetary gearbox, and a programmable digital driver, ensuring reliability and precision.

Compliance with major maritime classification societies (ABS, BV, LR, RMRS) and rigorous environmental testing (shock, vibration, humidity) makes these actuators suitable for the harshest environments found on ships and offshore platforms. The elimination of hydraulic oil not only simplifies the maintenance schedule but also eliminates a significant environmental hazard. Whether applied to a large diesel generator set or a steam turbine governor, the EM-80/EM-300 series stands as a cost-effective, high-performance solution for modern rotary actuation needs.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA