Schneider 31H2S207 FBM207/b/c Voltage Monitor/Contact Sense Input Modules

Fault self diagnosis: It has basic fault diagnosis function. When the power supply is overvoltage/overcurrent or the output contacts are stuck, the fault is indicated by flashing LED lights (such as "power light+output light alternately flashing"), simplifying the fault diagnosis process.

compatible system

The core is compatible with Schneider IASeries industrial automation systems and can seamlessly link with Schneider PLCs (such as Modicon M262, M340), human-machine interfaces (HMI), and other control components. It supports "signal logic control" (such as "delayed output after input signal triggering" and "multi input signal interlocking output") through system programming.

Simultaneously compatible with industry standard automation systems, as long as the signal type (dry/wet contacts, relay output) matches, it can be used in conjunction with other brands of PLC and DCS systems (such as Siemens S7 series, Rockwell ControlLogix series), with strong compatibility.

Installation specifications and safety certification

Installation requirements

Electrical installation: Power wiring should distinguish between "phase line (L)" and "neutral line (N)", and input/output circuits should be separately wired to avoid parallel laying with power cables (such as 380V AC motor cables) (spacing ≥ 300mm) and prevent electromagnetic interference; After the wiring is completed, it is necessary to tighten the terminal screws to avoid loosening and poor contact.

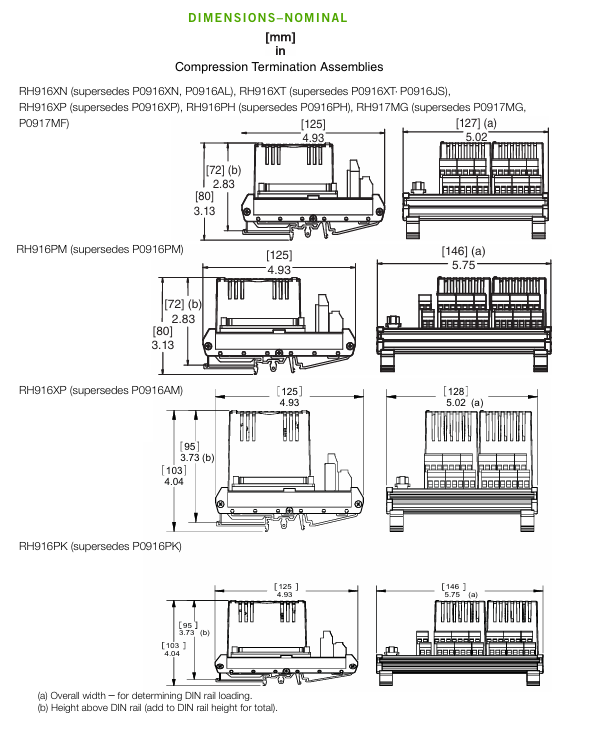

Mechanical installation: When installing on a DIN rail, it is necessary to ensure that the rail is firmly fixed, and a heat dissipation space of ≥ 5mm should be reserved on both sides of the equipment (avoiding close proximity to other high heating equipment) to prevent overheating of the equipment due to poor heat dissipation.

Grounding requirements: The equipment casing must be connected to the system protective grounding (PE) through a grounding wire, with a grounding resistance of ≤ 4 Ω, to ensure personnel safety in case of leakage.

Safety Certification

Compliant with international safety standards: UL 508 (Industrial Control Equipment Safety Standard), IEC 60947-1 (General Standard for Low Voltage Switchgear and Control Equipment), ensuring that the product meets industrial requirements in terms of electrical safety, mechanical strength, and other aspects.

Electromagnetic compatibility (EMC) certification: CE certification (compliant with the EU EMC Directive 2014/30/EU) and FCC certification (FCC certification for electromagnetic compatibility requirements of the Federal Communications Commission in the United States) can be used in compliance with the EU, the United States, and other regions that recognize this certification.

Application scenarios and maintenance recommendations

Typical application scenarios

Manufacturing production line: used to connect sensors (such as photoelectric sensors to detect whether the workpiece is in place) and actuators (such as cylinder solenoid valves) on the production line, achieving automated control of "workpiece in place → triggering solenoid valve action → pushing workpiece".

Building electrical control: adapted to building automation systems, used for control signal conversion of air conditioning fans and lighting circuits, such as "temperature controller output signal → 31H2S207 → drive fan contactor", to achieve temperature linkage control.

Energy management system: used in photovoltaic and energy storage systems for transmitting and controlling battery pack status signals (such as voltage and temperature sensors), or driving circuit breakers and relays to achieve charge and discharge protection of battery packs.

Maintenance Recommendations

Regular inspection: Check the terminal wiring for looseness and the LED indicator light for normal operation every 3 months. Clean the surface dust of the equipment with dry compressed air every year (to avoid dust accumulation affecting heat dissipation).

Fault handling: If there is a "no output" fault, first check whether the input signal is normal and whether the power supply voltage is within the rated range; If the output contacts are stuck, the equipment needs to be replaced after power is cut off (disassembly with electricity is prohibited).

Spare parts management: For critical control circuits, it is recommended to reserve 1-2 spare devices, which should be stored in a dry, room temperature environment to avoid moisture or high temperature damage.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands