Bently Nevada 3300 XL High Temperature Proximity Detection System (HTPS)

Combining the dual value of "online monitoring and protection" and "research and development/troubleshooting": it is used for real-time protection of key equipment in industrial sites, and also supports turbine mode shape analysis, helping new machine research and development and old machine fault diagnosis (such as shaft cracks, bearing failures, dynamic and static friction, etc.).

330303 Smooth Shell (with mounting bracket) A (total shell length, 0.6-9.9in, 0.1in increments), B (hard wire length), C (total length), D (armor), E (certified) 330303-060-10-90-00-00 (shell 6.0in, hard wire 1m, total length 9m, no armor, no certification)

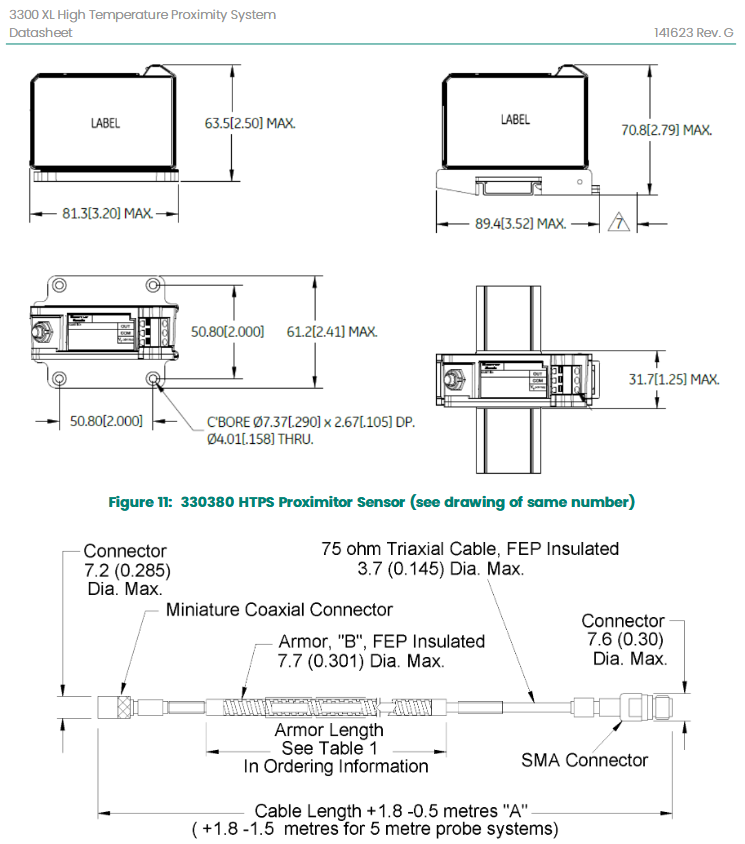

2. Sensor model (330380 series)

Replace the old model 330300, with a core distinction of "installation method" and parameters:

Selection parameter A (total length+installation): 90=9m panel installation, 91=9m DIN installation, 92=9m without installation hardware;

Selection parameter B (certification): 00=no certification required.

3. Accessories and extension cables

Backup extension cable (330330): It needs to match the original probe serial number, with a length of 4m (040)/7m (070)/8m (080), supporting armor (01 with/00 without);

On site wiring cable (132501): 18AWG (1.0mm ²) 3-core shielded wire, length 2-99 feet (0.6-30m), with wire lugs at both ends;

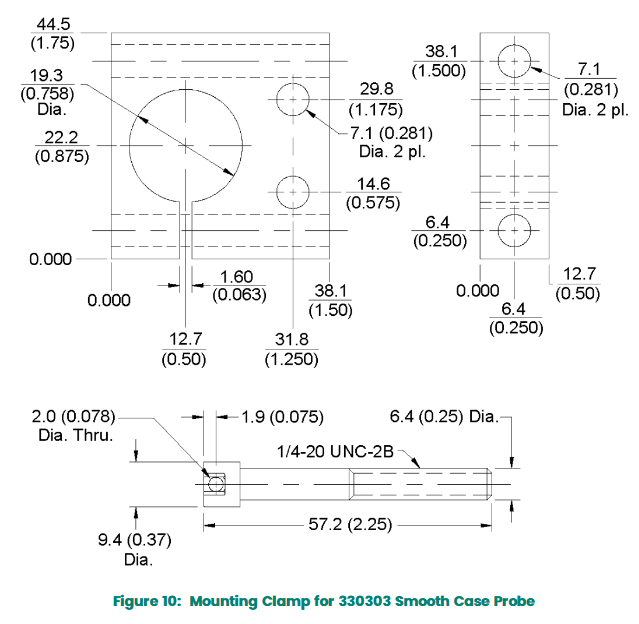

Documents and Bracket: 125M6030 (User Guide), 159132 (Performance Specifications), 134835-01 (330303 Probe Backup Installation Bracket).

Compliance and Precautions

1. Compliance certification

Electromagnetic compatibility: compliant with EU CE certification;

Environmental Protection: Compliant with RoHS Directive 2011/65/EU;

Wireless interference: Complies with FCC Part 15 regulations (does not generate harmful interference, and is tolerant of interference).

2. Key precautions

Target material requirements: System accuracy based on Bently Nevada AISI 4140 steel target (diameter ≥ 31mm), using other target materials may affect accuracy;

Small shaft diameter measurement: When the shaft diameter is less than 76mm (3in), attention should be paid to the electromagnetic interference of the probe (radial vibration probe spacing ≥ 54mm, axial position ≥ 64mm). When the shaft diameter is less than 152mm (6in), it will cause changes in the proportional coefficient, and reference should be made to specification 159132;

Pressure and Leakage: The probe is designed to seal the pressure difference between the tip and the housing, but pressure testing is not conducted at the factory; High/low pH solutions may corrode the probe tip and cause leakage. Bently Nevada is not responsible for any leakage damage, and the leaking probe is not covered by the service plan warranty.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands