Bently Nevada 3500/42M Proximity Seismic Monitor

Maritime certification ABS (Ship and Marine Applications), DNV GL (Classification of Ships, Marine Equipment, and High Speed Light Ships)

Hazardous Area Certification - CSA/NRTL/C: Class 1, Division 2

-ATEX/IECEx: II 3 G, Ex nA nC ic IIC T4 Gc, etc. (specific I/O modules need to be coordinated)

Ordering and Supporting Information

1. Product model coding rules

3500/42M - AA - BB, among which

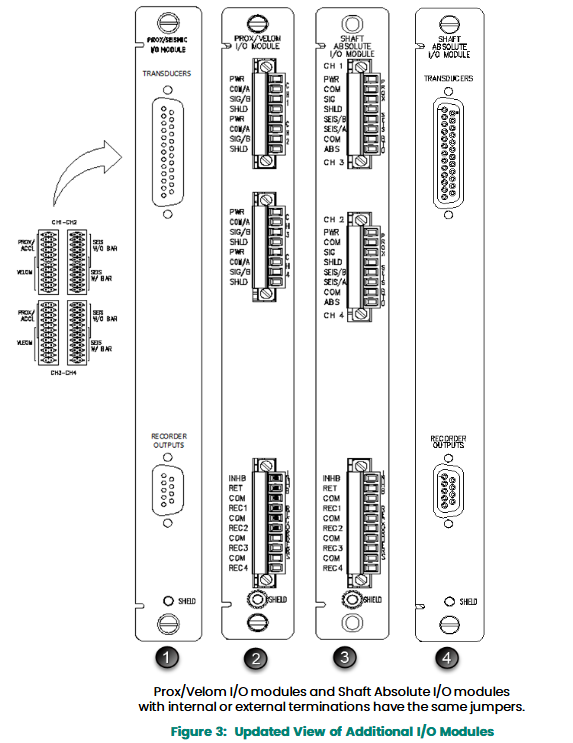

AA (I/O module types): such as 01 (Prox/Seismic I/O module with internal terminal), 04 (4-channel Prox/Accel I/O module with internal isolation switch), etc. (there are a total of 10 options, please refer to the "1/O Module Types" table in the document);

BB (hazardous area certification option): 00 (no certification), 01 (CSA/NRTL/C), 02 (ATEX/IECEx/CSA, only applicable to some AA types).

2. Supporting components

External terminal blocks: such as 125808-02 (European connector proximity terminal block), 128702-01 (European connector recorder terminal block), etc;

Cable: 3500 sensor signal cable (129525 series, length of 5~100 feet optional, including assembled/unassembled options), external terminal block cable (129529 series, with the same specification as the sensor cable);

Spare parts: Monitor body (176449-02), I/O modules (128229-01, 138708-01, etc.), connector splitter (00530843, etc.).

3. Software and hardware requirements

Firmware version: For absolute axis monitoring, 3500/42M firmware version B is required, while REBAM requires 3500/40M firmware version 2.1;

Software version: 3500/01 software 2.50 and above, 3500/02 software 2.20 and above, 3500/03 software 1.21 and above (different functions require higher versions, see document "Firmware&Software Requirements" for details).

Other instructions

Brand affiliation: Bently Nevada is a business under Baker Hughes, and product technical support and document updates can be obtained through Bently.com;

Document version: The data manual version is 143694 Rev. V, released in 2020. Specifications may change without notice, and the actual product shall be subject to the latest document;

Application scenario: Mainly used for monitoring the status of rotating machinery in the fields of power, petrochemicals, intelligent manufacturing, etc., such as preventive maintenance of key equipment such as steam turbine generators, centrifugal compressors, and motors.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands