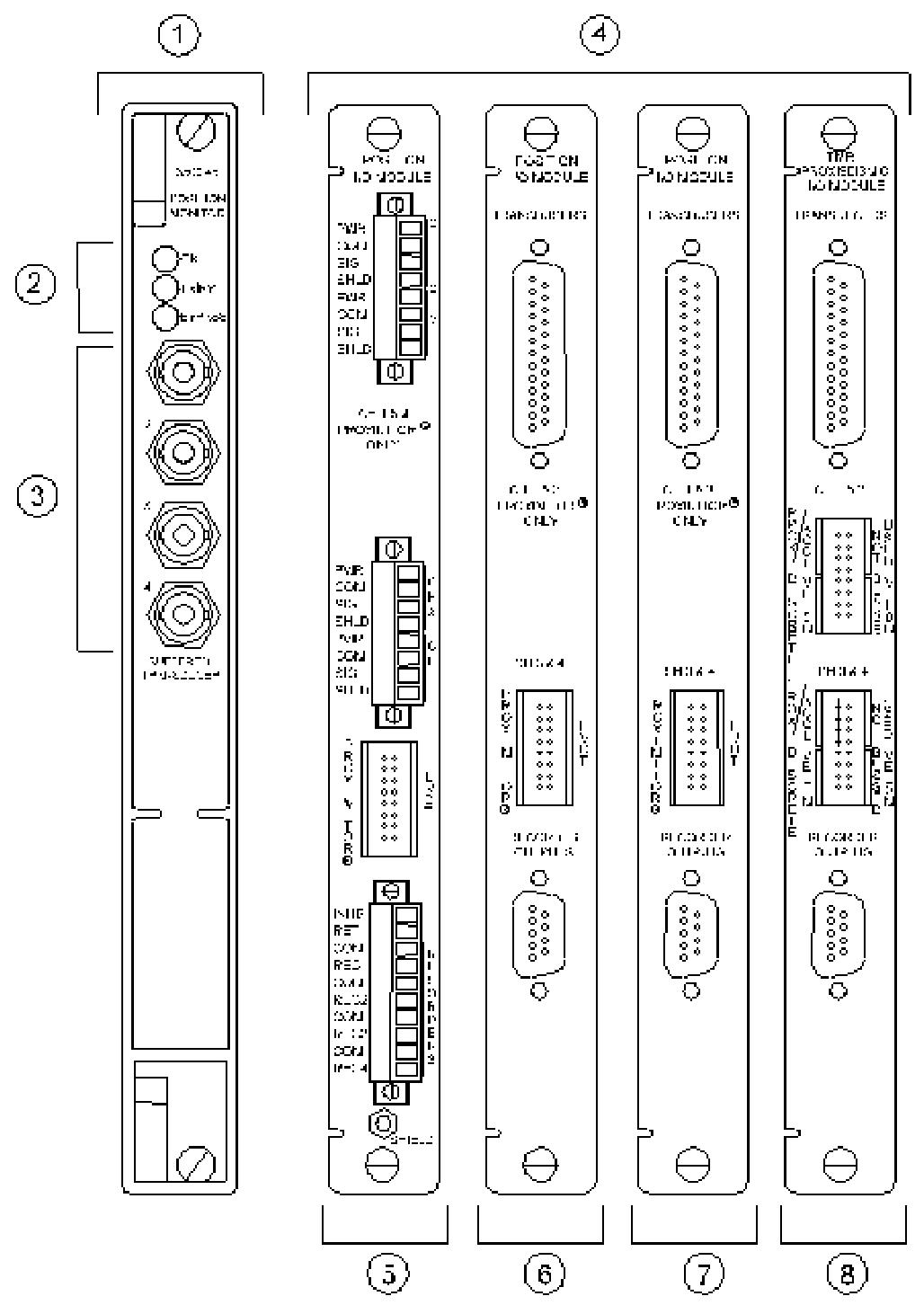

Bentley 3500/45 Position Monitor

Voting mechanism: When the deviation between the output of a module and other modules exceeds the set threshold (such as 5%), an event log is triggered to ensure data consistency.

3. Typical configuration examples

Turbine thrust monitoring:

Sensor: 3300XL 8mm Proximitor with a sensitivity of 200 mV/mil.

Channel configuration: 1-2 channels are set as thrust positions, with a full range of 25-0-25 mil, an Alert threshold of 15 mil, a Danger threshold of 20 mil, and a filtering frequency of 1.2 Hz.

Boiler pipeline expansion monitoring:

Sensor: 50 mm DC LVDT, sensitivity 0.10 V/mm (2.50 V/in).

Channel configuration: 3-4 channels are set for chassis expansion, with a full range of 0-50 mm and an alarm delay of 2 seconds, adapted to the slow change characteristics of thermal expansion.

Ordering and installation information

1. Component numbering rules

3500/45-AXX-BXX:

AXX: I/O module type (e.g. 01=internal terminal, 05=AC LVDT).

BXX: Authentication options (01=CSA/NRTL/C Class I, Div 2).

Example: 3500/45-01-01 represents an internal terminal module with CSA certification.

2. External components and spare parts

Terminal block:

Proximitor/DC LVDT: 125808-06 (Euro interface) or 128015-06 (terminal block).

AC LVDT: 141208-01 (Euro interface), supports signal conditioning and isolation.

Cable:

Sensor to terminal block: 129525 series, length 5-100 feet, supports assembly/non assembly.

Spare parts:

Module spare parts: 176449-04 (3500/45 complete machine), 135137-01 (internal terminal module).

Consumables: 00530843 (I/O module four pin splitter), used for sensor type matching.

3. Installation requirements

Space occupancy: The monitor occupies one full height front slot, and the I/O module occupies one full height rear slot, which needs to be used in conjunction with a 3500 rack.

Environmental compatibility:

Working temperature -30 ° C~65 ° C, storage -40 ° C~85 ° C, humidity ≤ 95% non condensing, in compliance with EN 61000-6-4 electromagnetic compatibility standard.

Explosion proof certification: Equipped with CSA certification module, suitable for Class I, Div 2 Groups A-D hazardous areas, meeting the needs of petroleum, chemical and other scenarios.

Application precautions

Sensor matching:

Differential expansion requires the use of an Extended Range Proximitor (e.g. 25 mm) to ensure that the range covers the expansion difference between the shaft and the casing.

It is recommended to use DC LVDT for casing expansion to avoid AC LVDT phase drift affecting accuracy.

Software version requirements:

TMR configuration requires 3500 configuration software 2.41 or above, and when using RPT for valve position, software 3.00 or above is required.

Maintenance suggestion:

Regularly verify the alarm function (such as triggering Alert/Ranger with input analog signals), and check the consistency between the LED status and the recorder output.

When hot plugging modules, power should be turned off to avoid static electricity damaging the circuit board (it is recommended to wear an anti-static wrist strap).

Summary

The 3500/45 position monitor provides accurate position parameter monitoring for rotating machinery through multi-channel and high-sensitivity design. Its modular configuration and TMR redundancy mechanism ensure system reliability, making it suitable for key fields such as power, petrochemicals, and metallurgy. Users can choose the appropriate combination of I/O modules and sensors based on the type of machinery and monitoring requirements, and achieve customized protection solutions through flexible software configuration, providing data support for the safe operation of equipment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands