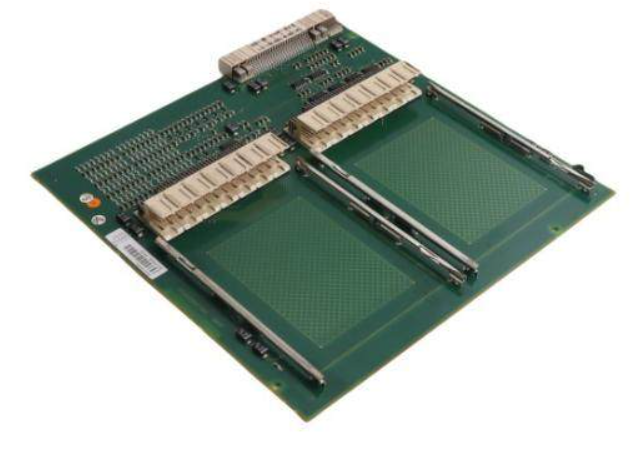

ABB 3ASC25H705/-7 High Performance Digital Control Controller

ABB 3ASC25H705/-7 High Performance Digital Control Controller

Product Overview

ABB 3ASC25H705/-7 is a high-performance digital control controller designed specifically for industrial environments, occupying a core position in complex industrial automation systems. It can accurately regulate various industrial equipment, achieve precise control of the operating status and parameters of key equipment such as motors, ensure stable, efficient, and precise operation of industrial production processes, and is widely used in multiple industrial fields such as manufacturing, energy, and chemical engineering. It is a key equipment for upgrading and optimizing industrial automation

Specification parameters

Model: 3ASC25H705/-7

Network interface: Equipped with 5 Gigabit Ethernet interfaces, including 2 1000Base-X full duplex single-mode/multi-mode fiber optic interfaces (SC/ST/FC interface optional) and 3 10Base-T/100Base TX/1000Base-T adaptive Gigabit Ethernet ports, meeting diverse network connection needs

Data processing method: using store forward exchange to ensure the accuracy and efficiency of data transmission

Working voltage: The input range of the DC power supply is DC9-24V, equipped with dual diode anti reverse connection and double thyristor protection to enhance the safety of power supply connection

Compliance with standards: Compliant with IEEE802.3, IEEE802.3u, and IEEE802.3x standards, with good compatibility

Working temperature: The working temperature range is -40 ° C to 70 ° C, which can adapt to extremely harsh industrial environments

Structure Design

Low power consumption, fanless design, using stainless steel casing and aluminum alloy panel, standard 6U architecture, pinhole connector, with excellent impact and seismic resistance, suitable for harsh working conditions

Port configuration

The front-end is equipped with dual USB 2.0 and single RS232/RS422/RS485 interfaces; The backend is equipped with dual USB 2.0, dual RS232, dual Ethernet ports, keyboard/mouse VGA、 parallel port

Keyboard and Display: The membrane keyboard has 60 input keys, including 10 definable function keys; Equipped with a high brightness 12.1-inch TFT LVDS LCD screen (optional touch screen)

Scalability: 21 slot motherboard, capable of expanding up to 15 user IO templates; Adopting AT96 open architecture bus, it is convenient for users to customize templates

Power output: AT power supply, power 60W, output voltage+5V/+12V/-12V

Dimensions: 445 (width) x 266 (height) x 245 (depth) mm

Weight: 6.0Kg

Relative humidity: can withstand up to 90% (at 55 ° C)

Processor related: Adopting Intel dual core technology processor, packaged in Socket 479 FCPGA. The Core Duo processor has a 2MB large capacity L2 cache with a frequency range of 1.66GHz-2.33GHz; The Core single processor has a 2MB large capacity L2 cache with a frequency range of 1.66GHz-1.83GHz; Low voltage Core Duo processor with 2MB large capacity L2 cache and frequency range of 1.50GHz to 1.83GHz. System front-end bus 667MHz, using Intel Mobile Series 945GM+ICH7M chipset

Memory and Storage: Equipped with 2 DDR2 memory expansion slots, supporting up to 4GB (2GB X 2 slots) DDR2 (DDR2-400/533/667/) memory, supporting dual channels. 2 IDE channels, supporting 4 IDE devices, supporting up to DMA-100/133 transfer mode; Supports 4 SATA channels, 4 SATA -150/300 hard drives, AHCI and (RAID 0/1) disk array modes. Onboard 1 compact flash card slot (CF card as IDE device)

Monitoring function: Supports 1-255 second software programmable watchdog timer. Equipped with hardware monitoring functions such as processor temperature and voltage monitoring, system environment temperature monitoring, fan speed monitoring, and system voltage monitoring

Core functions

Precise control of motor: integrating multiple advanced control algorithms, such as vector control, direct torque control, etc., can achieve high-precision control of motor position and speed. In the motor testing process of electric vehicle manufacturing, the motor speed and torque output can be accurately adjusted to ensure that the motor performance meets the standards.

Multi signal interaction: With rich sensor interfaces, it can connect various sensors and collect real-time parameter signals such as motor operating status, temperature, pressure, and position. In the control scenario of chemical reaction vessels, the heating, cooling, and material addition process of the reaction vessel can be controlled in real time based on the collected signals by connecting temperature and pressure sensors.

System collaborative integration: It can work in conjunction with devices such as motors and encoders, and monitor and control motor operation in real-time based on sensor feedback. It can also cooperate with control systems such as PLC to achieve high-precision motor motion control and production line automation monitoring. On the automated assembly line of the smart factory, in collaboration with PLC, precise control of the operation of each workstation equipment is achieved to improve production efficiency and product quality.

Precautions

Installation environment considerations: Avoid installation in dusty environments where dust accumulation may block heat dissipation channels, affect equipment heat dissipation, reduce performance, and even cause malfunctions. Stay away from areas with corrosive gases to prevent gas from corroding electronic components and shorten the service life of equipment. At the same time, it is necessary to maintain a safe distance from strong electromagnetic interference sources to prevent electromagnetic interference from affecting signal transmission and equipment operation stability.

Electrical connection standard operation: Strictly follow the product manual for electrical connection, ensure that the wiring is firm, and avoid virtual connections that may increase contact resistance, cause heating, unstable signal transmission, and other problems. Carefully distinguish the wiring of different types of interfaces and strictly prohibit misconnecting to avoid damaging the equipment. When connecting the power supply, be sure to confirm that the input power supply voltage is within the range of DC9-24V and the polarity is correct to prevent the power supply from being reversed and burning out the equipment.

Software programming and maintenance: Programming must follow the specifications and standards provided by ABB to ensure correct and reliable control logic. Regularly update the software of the device, backup important programs and data before the update, and prevent unexpected data loss during the update process. Obtain software update packages from official channels designated by ABB to avoid the use of unauthorized or unknown software, in order to prevent the introduction of security risks or device compatibility issues.

Application scenarios

Manufacturing industry: In automobile manufacturing factories, mechanical arms and conveyor equipment motors are used to control automated production lines, achieve precise handling, welding, and assembly of components, and improve production efficiency and product quality. In the electronic equipment manufacturing workshop, precise control is carried out on the motors of SMT surface mount machines, plug-in machines and other equipment to ensure the accurate installation of electronic components.

Energy industry: In smart grid substations, remote monitoring and control of power equipment motors such as circuit breakers and isolating switches are achieved to ensure the safe and stable operation of the power system. In wind power plants, the pitch motor and yaw motor of the wind turbine are precisely controlled, and the angle and direction of the wind turbine blades are adjusted in real time according to the wind speed and direction, achieving efficient capture and conversion of wind energy.

Chemical industry: In the chemical production process, precise control is carried out on the reaction kettle stirring motor and material conveying pump motor. According to the requirements of the reaction process, the motor speed and running time are accurately adjusted to ensure the smooth progress of the chemical reaction. In the process of oil and gas extraction and transportation, control pipeline pump motors and compressor motors to monitor and regulate pipeline pressure and flow in real time, ensuring energy transportation safety.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands