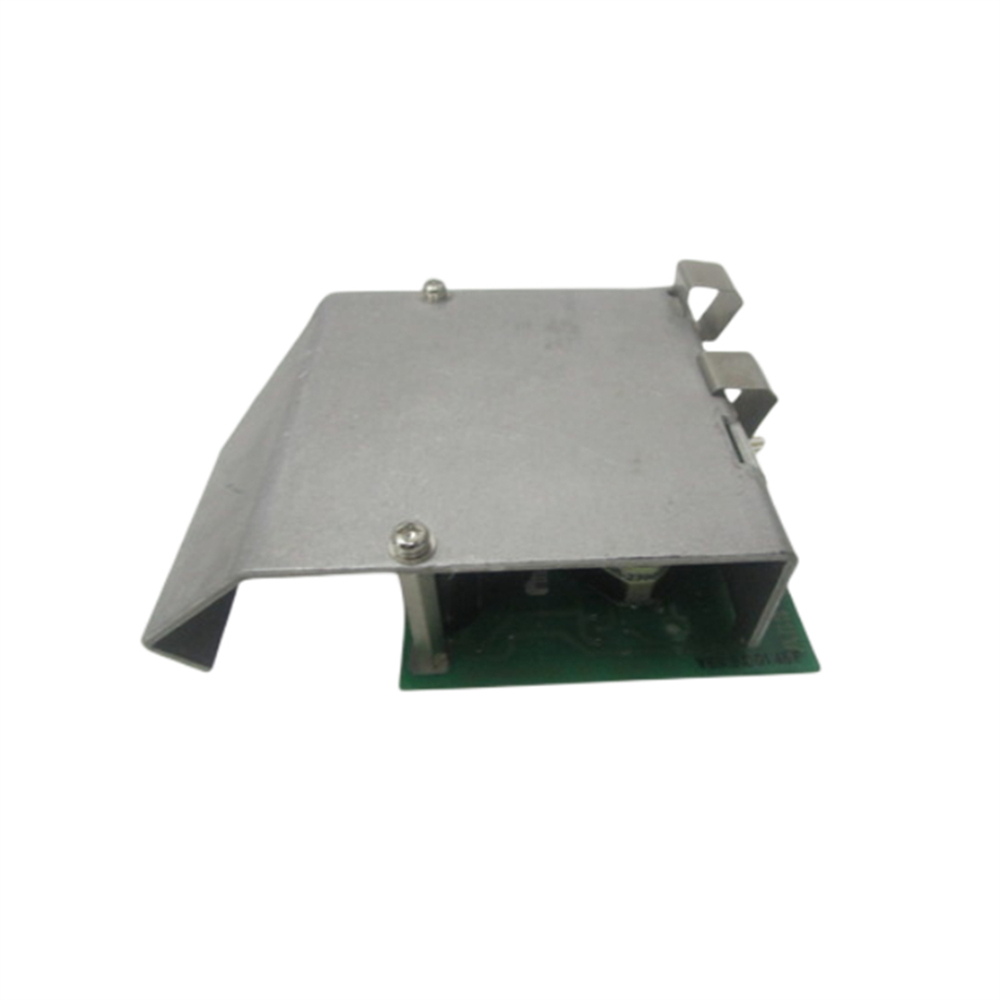

ABB 3BHB003689 Multifunction Controller Module

ABB 3BHB003689 Multifunction Controller Module

Explanation of Specification Parameters

Electrical parameters

Working voltage: support 90 - 264V AC wide voltage input, adapt to different regions, different scenarios of the power supply environment, with ±10% of the voltage fluctuation adaptability, can effectively deal with the common industrial site voltage instability, to ensure the continuous and stable operation of the equipment.

Output characteristics: output 24V DC stable DC power supply, connecting sensors, small controllers and other equipment to provide reliable power support; output frequency of up to 50kHz, suitable for signal response speed requirements of higher control scenarios, such as high-speed motion control, rapid data acquisition.

Performance Parameters

Processing speed: Equipped with a high-performance 32-bit processor with a processing speed of up to 2MHz, it is able to quickly analyse complex control instructions and process a large amount of sensor data and control signals in real time, ensuring high real-time and response speed of the system to meet the needs of industrial automation for efficient computing.

Memory capacity: with 512KB user memory space, it can store complex control procedures, system configuration parameters, and historical data during operation, supporting the rapid invocation and operation of the programme, and guaranteeing the stable execution of industrial control logic.

Physical Parameters

Dimensions: the product dimensions of 150mm × 100mm × 70mm, compact design makes it easy to install and layout in control cabinets, equipment chassis and other space-limited environments, saving installation space and facilitating system integration.

Weight: the overall weight of about 0.5kg, lightweight design facilitates the installation, handling and maintenance of the equipment, reducing the requirements of the equipment bearing structure.

Operating Environment Adaptability

Temperature range: Stable operation in extreme temperatures ranging from - 40°C to + 85°C. Whether it is a cold outdoor scene or near a high-temperature industrial furnace, it ensures the normal operation of the equipment and guarantees the continuity of industrial production.

Humidity range: the humidity range is 5% - 95% without condensation, in humid workshops, coastal areas and other environments, it can effectively resist moisture erosion, avoid moisture damage to electronic components, and improve the reliability of the product in complex environments.

Performance Advantages

powerful communication ability

Protocol support: Support Ethernet (Ethernet), Modbus TCP, Profibus DP, DeviceNet, CANopen and other mainstream industrial communication protocols. Ethernet interface can achieve high-speed data interaction with the host computer and monitoring system, which is convenient for remote monitoring and management; Modbus TCP protocol facilitates communication with devices produced by different manufacturers that follow the protocol and achieves flexible system integration; Profibus DP, DeviceNet and CANopen protocols are suitable for distributed device control in industrial automation networks, ensuring efficient and cooperative work between devices. The Profibus DP, DeviceNet and CANopen protocols are used for distributed device control in industrial automation networks, ensuring efficient co-operation between devices.

Communication speed: Ethernet communication speed can reach up to 100Mbps, which can quickly transmit a large amount of real-time data, such as in automated production lines, can be uploaded in a timely manner to the massive amount of data collected by the sensor, and quickly give control instructions to ensure the efficient operation of the production line; other serial communication interfaces also have a high transmission rate, to meet the communication needs of different devices.

Excellent reliability

Materials and processes: high-quality industrial-grade electronic components, after strict screening and testing to ensure the high reliability and stability of each component; the use of advanced surface mount technology (SMT) and multi-layer circuit board design to improve circuit integration and electrical connection quality, reducing the potential for faults such as soldering, short-circuiting, etc.; circuit boards for the three-proof (moisture-proof, dust-proof, corrosion-resistant) treatment, to enhance the anti-interference ability of the product in harsh industrial environments, and the ability to resist interference. Three-proof (moisture-proof, dust-proof, corrosion-proof) treatment of the circuit board to enhance the anti-interference ability and durability of the product in harsh industrial environment.

Testing and certification: Passing CE, UL, ISO 9001 and other international authoritative certificates, the products have reached the international leading level in terms of electrical safety, electromagnetic compatibility and environmental adaptability. For example, in the electromagnetic compatibility test, it can effectively resist strong electromagnetic interference from industrial sites without interfering with the surrounding equipment, ensuring stable system operation.

Flexible programming and expansion

Programming language support: It supports a variety of programming languages in accordance with IEC 61131-3 standard, including Ladder Diagram (LD), Function Block Diagram (FBD), Instruction List (IL), Structured Text (ST) and Sequential Function Chart (SFC). Engineers can choose the appropriate programming language according to their own programming habits and project requirements, which is convenient for program development and debugging; at the same time, the rich function libraries and instruction sets can greatly improve programming efficiency and shorten the project development cycle.

Expandability: With good expandability, the number of I/O points can be increased by connecting expansion modules to meet the needs of industrial automation projects of different scales; communication interfaces and special function modules can also be flexibly expanded according to the actual application scenarios, such as adding analogue input/output modules to achieve precise control of continuous physical quantities such as temperature and pressure, or adding high-speed counting modules to meet the needs of high-speed motion control.

Comparison of Similar Models

Comparison with 3BHB003690

Functional Focus: 3BHB003690 is optimised for high-speed data acquisition, which is more suitable for scenarios requiring high data acquisition speed and accuracy, such as precision instrument inspection, high-speed production line monitoring, etc. 3BHB003689 is more balanced in terms of comprehensive performance, which is not only equipped with good data processing capability, but also has excellent performance in terms of communication flexibility, extensibility and universality, which is suitable for most of the industrial automation control scenarios. The 3BHB003689 is more balanced in terms of comprehensive performance, not only with good data processing capability, but also with excellent performance in communication flexibility, scalability and versatility, which is suitable for most industrial automation control scenarios.

Differences in performance parameters: 3BHB003690 has more high-speed data acquisition channels and higher sampling frequency; 3BHB003689 has advantages in memory capacity, types of communication protocols and I/O expansion capability, which enables it to store more complex programmes and connect to more different types of devices.

Comparison with other models in the same series

Different models of the same series are usually designed for specific application scenarios or industry requirements. Some models focus on digital control and are suitable for industrial scenarios where switching control is the main focus, such as relay control circuits, motor start/stop control, etc. The 3BHB003689 is more outstanding in its ability to integrate analogue and digital control, and can handle multiple types of signals at the same time to achieve precise control of continuously changing physical quantities (e.g., temperature, pressure, flow rate) and discrete state quantities in industrial processes, which is widely used in process control, robotics, and other industrial applications. It is widely used in process control, robot control, automated production lines and other fields that require high control precision and diversity.

Application Scenario Analysis

Automated production line

Automobile manufacturing: In the automobile assembly line, 3BHB003689 can be connected to various types of sensors (such as position sensors, torque sensors, vision sensors) and actuators (such as robot arms, tightening guns, conveyor belt motors). Through real-time acquisition of sensor data, the robot arm is precisely controlled to complete the accurate assembly of parts, the torque of the tightening gun is monitored to ensure the quality of bolt fastening, and the running speed of the conveyor motor is coordinated to achieve orderly delivery of materials, thus improving the automation of automotive production and product quality.

Food and beverage production: In the food and beverage filling production line, the module can control the filling volume of the filling machine and the capping strength of the capping machine, and through the cooperation with temperature sensors and liquid level sensors, it can real-time monitor the temperature, liquid level and other parameters in the production process to ensure that the quality of the product meets the standards; at the same time, it communicates with the MES system of the production line to achieve the uploading of the production data in real time and the delivery of the production plan, so as to improve the production and management efficiency. management efficiency.

Process control field

Chemical production: In the chemical reactor control system, 3BHB003689 connects temperature, pressure and flow sensors to collect process parameters in the reactor in real time. According to the preset process control requirements, through the control of regulating valves, pumps, stirrers and other equipment, accurately adjust the flow rate of reaction materials, reaction temperature and stirring speed, to ensure that the chemical reaction is carried out in safe and stable conditions, to improve the yield and quality of chemical products, while safeguarding the safety of the production process.

Energy and Power: In the boiler control system of thermal power plants, the module monitors the boiler's water level, steam pressure, temperature and other key parameters, and controls the operation of feed pumps, fans, safety valves and other equipment. Through real-time data analysis and control strategy adjustment, it achieves efficient combustion and stable operation of the boiler, improves power generation efficiency, and reduces energy consumption; at the same time, it integrates with the DCS system of the power plant to achieve centralised monitoring and management of the entire power generation process.

Robot control scenarios

Industrial Robot: In the welding robot workstation, 3BHB003689 acts as the core control module, receives welding task commands from the host computer, and calculates and controls the motion trajectory of each joint of the robot, welding speed, welding current and other parameters according to the requirements of the welding process and the kinematic model of the robot. By cooperating with vision sensors, it can achieve accurate positioning of the welding position and seam tracking to ensure the consistency and stability of the welding quality, which is widely used in welding operations in automobile manufacturing, machining and other industries.

Collaborative robots: In electronic assembly workshops, collaborative robots use 3BHB003689 to achieve safe collaboration with workers. The module controls the robot's movement speed and strength, and automatically reduces the speed or stops the movement when it detects that the distance to the worker is too close to ensure personnel safety; at the same time, according to the requirements of the product assembly process, it accurately controls the robot to complete the operations of grasping, placing, and assembling the electronic components, so as to improve the assembly accuracy and production efficiency.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands