Woodward 505 Turbine Digital Controller

Woodward 505 Turbine Digital Controller

Overview

This manual is the second volume of the Woodward 505 turbine digital controller, mainly covering service tools, peripheral devices, application notes, operator interface, service menu program, PID setting understanding, hardware/operating system faults, and multiple appendix contents. It aims to help users understand the application, configuration, operation, and fault handling of the controller.

Service Tools

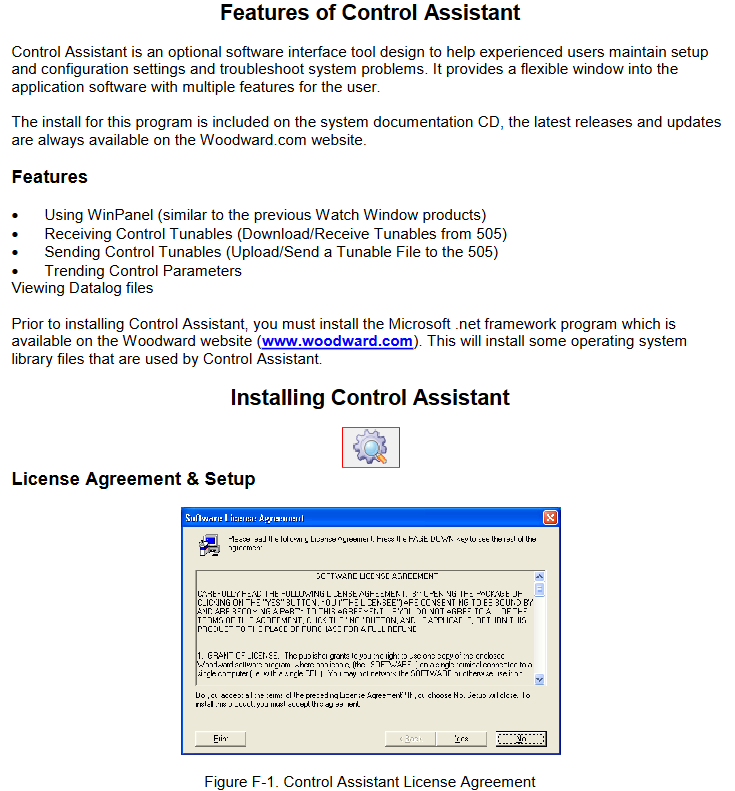

Control Assistant (CA): The main service tool that can upload and download adjustable parameters, display real-time trends of any I/O signals or control parameters, troubleshoot system issues by viewing system software variables, and analyze any data log files collected from the controller.

Servlink to OPC Server (SOS): Integrated with Control Assistant, running as a service on PC, converting Woodward proprietary Servlink data from 505 to OPC data. The Control Assistant tool will connect to the SOS server as a client, and customers who want to link from 505 to OPC data also need to connect to SOS.

AppManager (AppMan): Used to transfer files to and download files from the controller. It can set the controller's Ethernet port IP address and SNTP time synchronization IP address for network time protocol synchronization. It can also install software service package programs, start/stop control programs, or GUI programs.

Peripheral unit

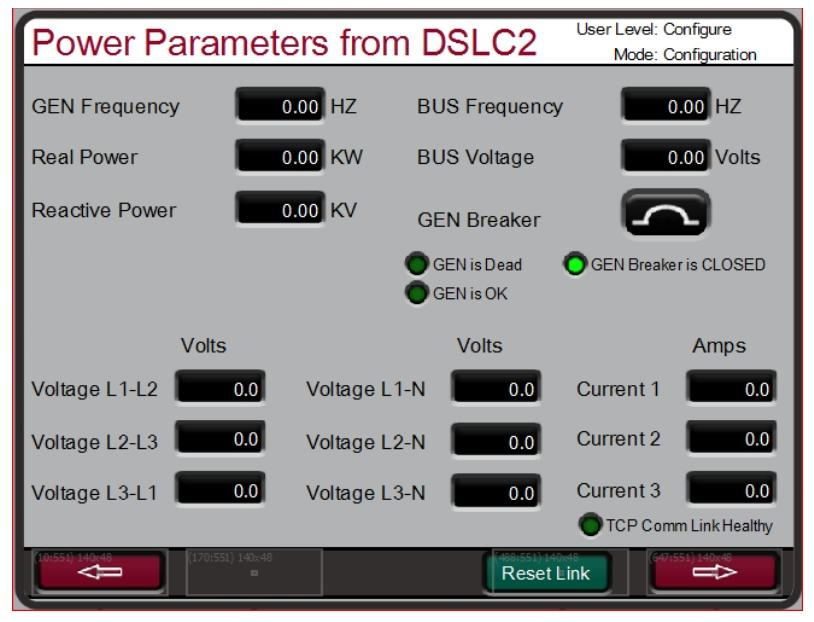

DSLC-2 (Generator Synchronizer and Load Control): Connected to the 505 controller, it can be used to accurately detect the three-phase RMS generator output power and perform generator circuit breaker synchronization. It can also configure generator load distribution, reactive power or power factor control, process control, and basic load control functions.

VariStroke II (electro-hydraulic actuator): A linear electro-hydraulic actuator designed to provide linear driving force for steam turbine control valves or valve frames, which can be directly networked with the 505 controller to reduce system complexity and wiring requirements.

MFR300 (Multi functional Relay): A multifunctional generator protection relay used to detect and protect small generators, integrating all generator protection functions into a universal device to reduce overall system installation complexity and cost.

LS-5 (Protection/Circuit Breaker Control Relay): Integrated with generator circuit breaker synchronization, power detection, and protection functions, designed to be used in conjunction with prime mover controllers such as 505 to achieve precise generator control and provide the required generator protection.

Servo Position Controller (SPC): can be used to connect the 505 digital controller with existing valve operators or Woodward actuators, suitable for action integration or situations where it is directly incompatible with the 505.

Real Power Sensor: Used to detect the active power generated by the generator or the active power flowing through the interconnection line. Woodward manufactures two types of active power sensors, one that can only detect power flow in one direction and the other that can detect power flow from the bus to the interconnection line.

Engine Generator Control Package/Load Sharing (EGCP-3 LS): Based on microprocessors, it is suitable for three-phase AC generators equipped with Woodward speed controllers and automatic voltage regulators. It integrates functions such as synchronizers, load control, dead bus closure systems, reactive power/power factor control, process control, power and energy metering, and protective relays.

Application Notes

Overview: This article introduces the capabilities of the 505 digital controller and its application in the system. By demonstrating typical steam turbine applications and explaining their functions, it provides assistance for application programmers to configure the 505. It also explains how to apply control parameters or combinations not shown in the system.

Example applications: Contains various example applications, such as pump or compressor discharge pressure control and turbine inlet pressure limitation, inlet pressure control and automatic synchronization, and generator power limitation. Each example has corresponding configuration instructions and startup and operation mode instructions.

Operator Interface

Graphic display and key input: The service panel of the controller consists of hard key command buttons, soft key command buttons, and a graphical user interface screen. The system operator communicates with the 505 system through the service panel.

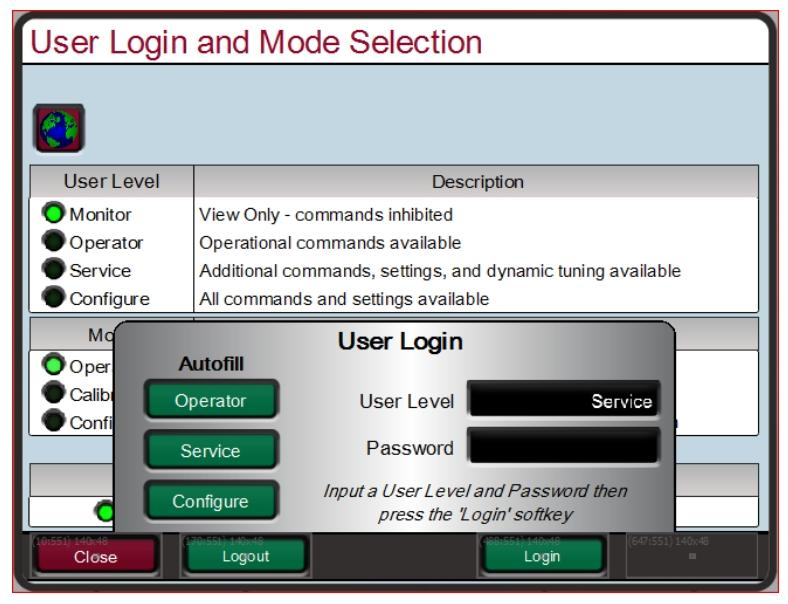

Service panel mode and user level: The 505 service panel has multiple modes (operation, calibration, configuration) and user levels (monitoring, operator, service, configuration). Different user levels determine the accessible and adjustable parameters and executable operations, and specific rules must be followed when adjusting values.

Service menu program

Overview: The service menu format of the 505 controller is easy to follow and can be used to customize the controller to better suit specific applications. Parameter adjustments in the service menu may affect system performance and should be handled with caution.

Service menu usage: As long as the controller is powered on, any user level can access the 505 service menu without shutting down the turbine. The permission to change these parameters is limited to the service user level and above, and requires entering the corresponding password for protection. Login to the service user level is required

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands