Motorola MVME162-223: High-Performance VMEbus Computing

Advanced Embedded Control Architecture

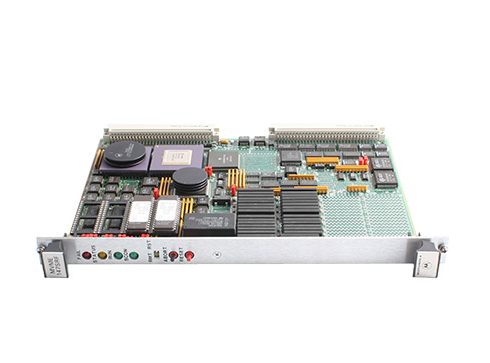

The Motorola MVME162-223 is an essential component in the evolution of the VMEbus Single Board Computer (SBC). Engineered to meet the rigorous demands of real-time industrial applications, it integrates the Motorola MC68040 microprocessor with a suite of versatile I/O features. This board is specifically designed for environments where deterministic performance and modularity are paramount. Whether used in high-speed manufacturing, laboratory research, or defense systems, the MVME162-223 provides a stable and powerful platform for sophisticated control logic.

A hallmark of the MVME162 series is its ability to handle complex multitasking operations without sacrificing speed. The MC68040 processor includes an integrated Floating Point Unit (FPU) and Memory Management Unit (MMU), which allows the MVME162-223 to execute high-level math and manage system resources with microsecond precision. This hardware iteration, the -223, focuses on providing a reliable 4MB memory footprint, optimized for systems that require high-speed data throughput and low latency.

Technical Specification Overview

| Category | Technical Detail |

|---|---|

| Processor | Motorola MC68040 (with integrated FPU/MMU) |

| DRAM Memory | 4MB with Parity Protection |

| SRAM Memory | 128KB Non-Volatile (Battery Backed) |

| VMEbus Compliance | A24/A32, D8/D16/D32 Master/Slave |

| I/O Expansion | IndustryPack (IP) Mezzanine Support (up to 4 slots) |

| Network Interface | Integrated Ethernet (82596CA Controller) |

| Serial Interfaces | Four Multi-protocol Serial Channels |

| Clock Frequency | 25 MHz / 33 MHz configurations |

Functional Intelligence and Modular Design

The IndustryPack Advantage

The MVME162-223 is renowned for its modularity, primarily achieved through its support for IndustryPack (IP) modules. This mezzanine technology allows system designers to add up to four independent I/O modules directly onto the SBC. By utilizing IP modules for analog-to-digital conversion, digital I/O, or motion control, users can condense a multi-card system into a single VME slot. This not only saves valuable backplane space but also reduces signal latency by keeping the I/O processing local to the CPU bus.

Data Integrity and Reliability

In industrial settings, data corruption can lead to catastrophic system failure. The MVME162-223 addresses this with parity-protected DRAM, which detects memory errors caused by electrical transients or environmental interference. Furthermore, the board includes 128KB of non-volatile SRAM (NVRAM). This memory area is backed by an onboard battery, ensuring that system configuration parameters, calibration data, and error logs are preserved even during a total power loss. This capability is essential for unattended operations in remote locations.

Diagnostic Capabilities and Hardware Health

To ensure maximum uptime, the Motorola MVME162-223 features integrated diagnostic firmware. Upon power-up, the module performs a comprehensive self-test of the CPU, memory, and peripheral controllers. Front-panel LED indicators provide real-time status of the board's health, including "Fail" and "Run" status. This allows maintenance personnel to quickly identify hardware issues without the need for specialized debugging equipment, significantly reducing Mean Time To Repair (MTTR).

Network Connectivity and Communication

The MVME162-223 is designed for the networked factory floor. It features an integrated 10Base-T Ethernet controller that handles data packets independently of the main processor, ensuring that network traffic does not interfere with time-critical control tasks. Additionally, the board provides four programmable serial ports and an integrated SCSI interface. These communication channels allow the MVME162-223 to act as a central hub, coordinating data between legacy PLC systems, modern workstations, and high-speed storage devices.

Primary Industrial Applications

The versatility of the MVME162-223 has made it a standard in several high-reliability sectors:

Aerospace & Defense: Flight simulators and ground control units where deterministic logic is essential.

Automotive Manufacturing: Coordinating high-speed robotic assembly lines and vision inspection systems.

Scientific Research: Data acquisition for particle accelerators and high-energy physics experiments.

Telecommunications: Management nodes for telephony switching and satellite ground stations.

Installation and Maintenance Guidelines

For optimal performance, the Motorola MVME162-223 should be installed in a VMEbus chassis with adequate forced-air cooling. The MC68040 processor and IndustryPack modules can generate significant heat; maintaining steady airflow is critical to prevent thermal stress. Users should also periodically verify the health of the onboard battery to ensure NVRAM data retention during scheduled maintenance shutdowns.

When handling the board, strict adherence to anti-static (ESD) protocols is required to protect the CMOS components and the sensitive IndustryPack connectors. Gold-plated VMEbus pins should be inspected for debris prior to insertion into the backplane. By following these original Motorola engineering standards, the MVME162-223 will continue to provide a stable, high-performance computing platform for decades of industrial service.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-