ABB REG216 Digital Generator Protection System

Comprehensive Analysis of ABB REG216 Digital Generator Protection System

With the continuous expansion of power system scale and the improvement of intelligence level, higher requirements have been put forward for the reliability, accuracy, and flexibility of generator and main transformer protection devices. ABB's REG216 and its classic version REG216 Classic, as fully digital generator and main transformer protection systems, have become important solutions in the field of modern power protection due to their modular hardware design, optional protection function library, fully digital signal processing, and powerful self checking and communication capabilities. This article will provide an in-depth analysis of the system from multiple dimensions, including system architecture, protection functions, technical parameters, and configuration options.

System Overview and Core Features

The REG216 system is designed specifically for the protection of generators and main transformers. Its hardware adopts a modular structure, and its software integrates a rich protection function library. Users can flexibly choose and configure protection schemes according to their actual needs. The system has the following core features:

Full digital signal processing: using a sampling rate of 12 times the rated frequency (600Hz for 50Hz systems and 720Hz for 60Hz systems), with a dynamic range of up to 15 bits, achieving high-precision and high stability signal acquisition and processing.

Modular hardware design: The system consists of two main parts: an interface unit (such as input transformer component 216GW62, auxiliary relay components 216GD61a/216GE61/216GA61/216GA62) and an electronic processing unit (such as processor 216VC624, analog input unit 216EA62), which are connected through shielded cables for easy expansion and maintenance.

Software configurable protection function: Provides a complete function library covering generator, transformer, and feeder protection. Users do not need programming knowledge and can activate and configure protection functions through PC tools (such as CAP2/316) in a "drag and drop" manner.

Continuous self checking and monitoring: Hardware has the ability to perform continuous self checking, while software performs periodic testing, greatly reducing the need for traditional periodic injection testing and improving system availability.

Flexible communication and integration: Supports multiple communication protocols such as RS232, LON bus, MVB process bus (compliant with IEC 61375), and can seamlessly integrate with station control systems to achieve data upload and remote control.

Detailed explanation of main protection functions

REG216 integrates dozens of standard protection functions, and the following are some key functions and their technical features:

1. Generator differential protection (87G)

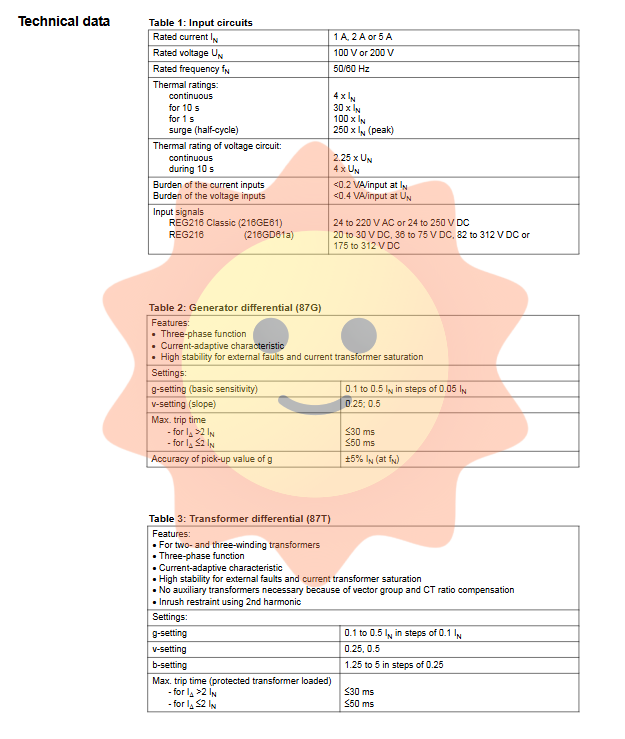

Adopting three-phase current adaptive characteristics, it has high stability and can effectively resist external faults and CT saturation effects. The action time shall not exceed 30ms when the current is greater than twice the rated value, with a sensitivity setting range of 0.1~0.5In and a step size of 0.05In.

2. Transformer differential protection (87T)

Suitable for two winding or three winding transformers, with built-in vector group and CT ratio compensation, without the need for auxiliary transformers. Provide second harmonic braking function to prevent excitation inrush current misoperation, with an action time not exceeding 30ms (>2In) under full load conditions.

3. Fixed time and inverse time overcurrent protection (51/51DT/67)

Provide overcurrent and undercurrent detection for phase and ground faults, supporting timed and multiple inverse time characteristics (such as normal inverse time, abnormal inverse time, and extreme inverse time). Directional overcurrent protection (67) has voltage memory function and is suitable for near end faults.

4. Grounding protection for stator and rotor (64S/64R)

100% stator grounding protection is based on the principle of voltage displacement, which can monitor the insulation status of the entire stator winding, covering both static and operating conditions. It needs to be used in conjunction with the REX010 injection unit and REX011 transformer module. The rotor grounding protection also provides continuous insulation monitoring, and the alarm and trip thresholds can be set between 100 Ω and 25k Ω.

5. demagnetization protection (40) and step loss protection (78)

The minimum reactance protection (40) is used to detect synchronous motor demagnetization faults, with circular characteristics, and can be set to trip within or outside the zone. The out of step protection (78) can detect sliding pole frequencies of 0.2-8Hz, identify the oscillation center position through impedance trajectory, and achieve two-stage tripping.

6. Voltage, frequency, and power protection

The system provides overvoltage/undervoltage (59/27), overvoltage/underfrequency (81), frequency change rate (df/dt), overexcitation (24), and power protection (32, including active, reactive, reverse power, etc.). All functions can be set for single-phase or three-phase measurement and have a voltage lockout mechanism.

7. Circuit breaker failure protection (50BF)

Support phase separation or three-phase current detection, with two independent delay stages (re trip and backup trip), and can be configured with remote trip function. The current setting range is 0.2~5In, and the action time is precise.

Hardware architecture and interface design

The hardware of REG216 is divided into two parts: process interface and electronic processing, both of which are installed in a standard 19 inch rack (6U height) and can be configured with up to 21 module positions.

Process interface module:

Input Transformer Component (216GW62): Provides CT/PT signal conditioning and electrical isolation, and can install up to 4 components (48 inputs).

Auxiliary relay components: including 216GD61a (8-way trip relay+16 way auxiliary relay+16 way optocoupler input), 216GE61 (16 way input relay), 216GA61 (16 way output relay), and 216GA62 (8-way trip relay, including surge suppression and economic circuit). These components achieve complete potential isolation of digital signals.

Electronic processing unit:

Processor Unit (216VC624): Based on the 80486DX-2 32-bit processor, software stored in Flash EPROM, data set stored in non-volatile memory, equipped with RS-423 interface for PC connection.

Analog input unit (216EA62): Supports 24 synchronous sampling channels, with 6 channels per group and a sampling rate of 600/720Hz.

Digital output unit (216AB61): controls the output auxiliary relay and has 32 outputs.

Trip output and binary input unit (216DB61): Provides 8 trip controls and 16 digital inputs, supporting external trip enable and lockout.

Auxiliary power supply unit (216NG6x): Input voltage range 36~312VDC, output 24VDC/150W, supports parallel redundancy.

The system connects various electronic units through parallel bus B448C (based on IEEE P896 draft) to achieve asynchronous data transmission and integrity verification.

Configuration, Debugging, and Maintenance

Users can configure REG216 using CAP2/316 software running on Windows NT/2000/XP systems. This software provides a graphical interface, supports online or offline programming, and has the following functions:

Parameter setting and saving: The fixed values, delays, and characteristic curves of all protection functions can be flexibly set and stored.

Real time monitoring: System measurement values (current, voltage, power, etc.), analog input waveforms, and digital input/output status can be viewed without triggering protective actions.

Event and waveform recording: The system has built-in event recording (256 records, timestamp resolution 1ms) and fault waveform recording function (up to 12 CT/VT channels, 16 binary channels), and waveform data can be analyzed through PSM505 software.

Testing function: Supports software simulation testing and external injection testing (such as using OMICRON tester) for easy debugging and regular calibration.

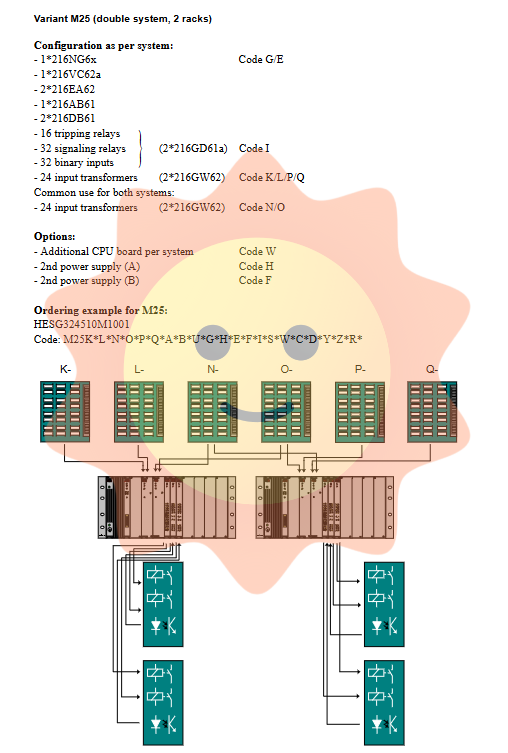

The system supports multiple redundant configurations, and users can choose from various architectures such as single system, single rack redundancy, and dual rack redundancy to ensure high availability for critical applications.

Technical Data Summary

Input circuit: rated current 1/2/5A, rated voltage 100/200V, frequency 50/60Hz, CT input load<0.2VA, PT input load<0.4VA.

Environment and electromagnetic compatibility: operating temperature -10 ° C~+55 ° C, storage temperature -40 ° C~+85 ° C, in compliance with multiple EMC and safety standards such as IEC 60255 and EN 61000.

Insulation and withstand voltage: Power frequency withstand voltage of 2kV/1min, impulse voltage of 5kV (1.2/50 μ s), insulation resistance>100M Ω.

Mechanical structure: Adopting ABB RESP standard cabinet, size 800 × 800 × 2200mm, weight 200~400kg.

Ordering and Configuration Guide

When ordering REG216, it is necessary to specify the system variants (such as M1~M25), rated parameters (current, voltage), input transformer configuration (CT/PT quantity and type), power supply voltage, communication protocol, etc. ABB provides a detailed questionnaire (1MRB520026-Ken) to assist users in completing customized configurations. The system supports various predefined configurations ranging from simple single systems to fully redundant dual systems, meeting the needs of power plants of different scales.

1SVR011718R2500

216EA62 1MRB150083R1/F1MRB178066R1/F

3BHE023784R1023 PP D113 B01-10-150000

3BHE050077R0102 UNS0881b-PV2

500AIM02 1MRB150022 R0002 1HDF 930412 X010

500AIM02 1MRB150022 R0002Y 1HDF 930412 X010

500AIM02 1MRB150022R001 1HDF 930412 X010

500BIM01 1MRB150024R0002

500BIM01 1MRB160024R0002

500BI001 1MRB150005R0001 1MRB200060/E

500BI001 1MRB150005R1/J

500BOM01 1MRB150023R0002

500CIM05 1MRB150077R1/B

500CMP04 HE401314/0001 1MRB150051R1

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA