ABB S500 Distributed Remote I/O System

ABB S500 Distributed Remote I/O System: The Core Architecture of Modular Industrial Automation

In industrial automation control systems, reliable, flexible, and efficient signal acquisition and output units are key hubs that connect field devices with upper level controllers. The S500 series hardware launched by ABB Stotz Kontakt GmbH is a high-performance, modular distributed remote I/O (R.I.O.) system designed to meet this demand. This article provides a comprehensive and in-depth analysis of the design concept, technical specifications, installation configuration, and functional applications of the system based on its official technical documentation.

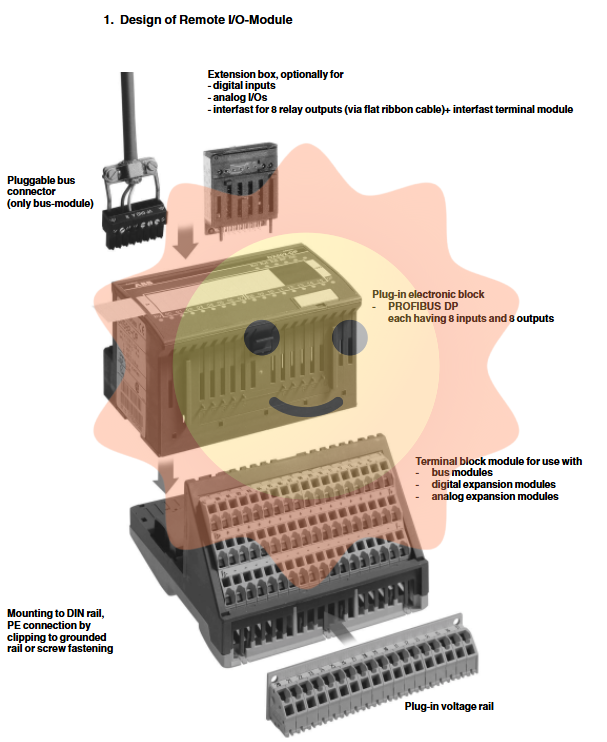

System Overview and Modular Design

The core of the S500 system lies in its high degree of modularity and scalability. The entire station consists of three types of components: bus modules, expansion modules, and expansion boxes, which are interconnected through lateral flat cables to form a compact unit.

Bus module: As the "brain" and network interface of the system, such as DX 501-DP and DX 502-DP modules. They integrate PROFIBUS-DP slave interface and come with local digital input/output (such as 8DI/8DO), responsible for communicating with the main controller (DP master) and managing the connected expansion modules. The main difference between the two is the supported PROFIBUS transmission rate (DX 501 is 1.5 Mbit/s, DX 502 is 12 Mbit/s).

Expansion module: used to increase the number of I/O points, with a variety of types:

Digital expansion modules: such as DX 511 (8DI/8DO), DI 511 (16DI), DO 511 (16DO).

Simulation extension modules: such as AX 511 (4AI/4AO), AI 511 (4AI), AI 512 (8AI).

Expansion box: Provides additional, more economical dedicated I/O points that can be directly plugged into the back of the bus module without occupying expansion slots. For example, AX 501 (3AI/1AO), DI 501 (4DI), DO 501 (used for connecting relay boards).

When building the system, first clamp the terminal blocks of each module onto a DIN rail (compliant with DIN EN 50022) and interconnect their backplane buses through flat cables. Subsequently, insert the corresponding electronic block (including processor and circuit) into the terminal block to complete the assembly. This physical separation design allows for separate replacement of electronic components without interrupting wiring, greatly improving maintenance convenience.

General Technical Information and Installation Specifications

1. Environment and Certification:

S500 is designed for industrial environments and needs to be installed inside control cabinets or enclosures. Its working temperature is 0 to+55 ° C, and the protection level is IP20. The product complies with the EU EMC Directive (89/336/EEC) and holds the CE mark and cUL certification (file number NRAQ E134 045), ensuring its reliability in terms of electromagnetic compatibility and safety.

2. Installation points and EMC measures:

Correct installation is the foundation for stable operation. The manual emphasizes key installation guidelines:

Safety first: Relevant safety regulations for emergency stop must be followed to ensure that the safety circuit can directly cut off the power side independently of the control system.

Power supply separation: The electronic system power supply (Vs+/Vs -) of the bus module is separated from the I/O point power supply (V+/V -). This allows in emergency situations, only the I/O power supply can be cut off through the safety circuit, while the bus communication remains online, facilitating diagnosis.

Grounding and shielding: Good protective grounding (PE) is crucial, and it is necessary to ensure a reliable connection between the DIN rail or mounting plate and the PE (it is recommended to use a minimum of 10 mm ² wire). All data and analog signal lines should use shielded cables. The shielding layer should be grounded with low impedance and large area at the cable entrance through shielding clamps or shielding strips to prevent electromagnetic interference.

Wiring isolation: Power cables, data cables, and signal cables should be laid separately, with a minimum distance of 1 meter, to avoid parallel wiring and reduce the interference of inductive loads (such as contactors and motors) on sensitive signals.

3. System latency:

The overall response time of the system is determined by multiple factors. The S500 slave station has inherent processing delays for different modules (such as DX 501-DP at 800 μ s and DI 511 at 400 μ s). In addition, it is necessary to consider the configurable filtering time for digital inputs (0.1-32 ms), the switching time for relay outputs (5-20 ms), and the conversion time for analog signals (approximately 2 ms per channel). These delays must be taken into consideration during system design and debugging.

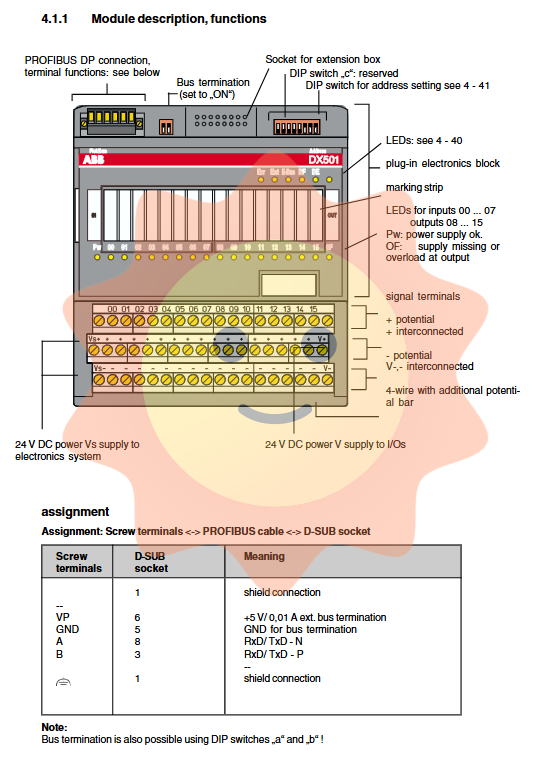

Deep Analysis of PROFIBUS-DP Bus Module

1. Address and configuration:

Each DP slave address is set through a 7-bit DIP switch (SW1-SW7) on the bus module, with a range of 1-125. The address is only read when the power is turned on, so a restart is required after modification. The system configuration is completed through the configuration software of the main station (such as ABB's 907 AC1131), and the correct GSD file (ABB_9521. GSD corresponds to DX 501, ABB_9520. GSD corresponds to DX 502) needs to be used. When configuring, it is necessary to follow a strict order: add the bus module first, then the expansion box (if any), and finally add the expansion modules in physical order.

2. LED diagnostic indicator light:

The dense LED on the front of the module provides intuitive status diagnosis:

Pw (power supply): System electronic power supply status.

Err (Error): System or configuration failure.

BF (Bus Fault): ROFIBUS communication timeout or parameter error.

DE (Data Exchange): Normal cyclic communication with the DP master station.

E-Bus: Communication status with expansion modules.

Ext (expansion box): The existence and status of the expansion box.

00-07 (channel indicator light): Real time status of corresponding I/O points.

OF (Output Fault): Indicates output short circuit, overload, or load power failure.

By combining and observing the status of these LEDs, problems can be quickly identified, for example, "Err flashing and E-Bus flashing" usually indicates a fault or connection interruption in an expansion module.

3. Parameter settings and diagnostic data:

When the DP master station starts, it will send parameter messages to the slave station to configure module behavior. Parameters can define functions such as "input delay time", "output behavior during faults (maintain last value or use alternative value)", "enable process alarm", etc. For simulation modules, range and limit monitoring can also be set.

S500 provides detailed diagnostic data, which is reported to the main station via PROFIBUS in a standard format of 19 bytes. Diagnostic information includes:

Station status: indicates whether the slave station is ready, whether the configuration matches, etc.

Identification related diagnosis: Accurately indicate in bitmap form which specific module (bus module, expansion box, or the number of expansion modules) has malfunctioned.

Equipment related diagnosis: Provide specific types of errors, such as "external load power loss", "output short circuit" (specific to channels), "analog signal disconnection or overload", etc.

Process alarm data: When enabled, it can report rising or falling edge events of digital input signals for rapid response to critical state changes.

Technical details of digital and analog expansion module

1. Digital modules (DX 511, DI 511, DO 511):

Input feature: Supports connecting 2-wire or 3-wire proximity switches (recommended "OFF" state current ≤ 1.2mA). The signal level of "1" is+13... 30 VDC, and the signal level of "0" is -30...+5 VDC. The typical value of input current is 5 mA.

Output characteristics: Transistor output, maximum 0.5A per channel, total current of 4A per module. The output has electronic short-circuit and overload protection, with short-circuit current limited to about 1.5A. The response time is extremely fast (≤ 50 μ s). When the inductive load is turned off, the output terminal will generate a maximum turn off voltage of about (V+-55V), and an external suppression circuit may be necessary.

2. Simulation module (AX 511, AI 511/512):

Flexible range selection: Each channel can be independently configured with a range of ± 10V, 0-10V, ± 20mA, or 4-20mA through jumper wires on the terminal board (connecting Sx and P terminals) and DIP switches inside the module. The P terminal also provides a power supply of+10V/2mA for connecting potentiometers.

High precision and resolution: using successive approximation ADC/DAC. In bipolar mode (such as ± 10V), the resolution is 11 bits+sign bits (i.e. 2048 step sizes); In unipolar mode (such as 0-10V or 4-20mA), the resolution is 12 bits (4096 steps). The basic accuracy is better than ± 0.4% of full scale at 25 ° C.

Diagnosis and protection: The module provides rich channel level diagnosis, which can detect faults such as "signal below 4mA (disconnection)", "short circuit", "over limit", "over limit", etc., and report them through diagnostic messages. The input channel allows for continuous overvoltage/overcurrent (maximum ± 30V/± 40mA) and has high reliability.

Expansion box: an economical and efficient specialized solution

The expansion box is directly inserted into the back of the bus module, without occupying the expansion slot or obtaining data from the E-Bus. Instead, it communicates through a dedicated parallel interface with extremely low latency (100-300 μ s).

AX 501: Provides 3 channels of 0-10V input (8-bit resolution) and 1 channel of 0-10V output, suitable for analog signal points with low precision requirements.

DI 501: Provides 4-channel 24VDC digital input with a simple structure.

DO 501: Provides 8 digital output interfaces specifically designed for connecting ABB Interfast series relay boards to achieve control of high-power or AC loads.

500CSP04 HE401314/00021MRB150051R2

500MBA01 1MRB150003R00021MRB200053/L

500MBA02 1MRB150003R000/B

500MBA02 1MRB150003R0003 1MRB200053/M

500MTM02 1MRB150020R0712 1HDF 930512 X010

500MTM02 1MRB150020R1102 1HDF 930512 X010

500MTM02 1MRK001967-AA 1HDF 930512 X010

500PB101 1MRB178009R00011MRB200064/C

500PSM02 1MRB150015R1 AD-272.100.20-01 AZ:C

500PSM03 1MRB 150038 R1 894-030375D 136-011100H

500PSM03 1MRB 150038 R1 894-030375D 136-011100H

500SCM01 1MRB150004R00011MRB200059/C

500SCM01 1MRB200059/C1MRB15004R0001

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA