KOLLMORGEN AKD ®- N servo drive

Grounding requirements: If the leakage current is greater than 3.5mA, double PE wiring or PE cables with a cross-section greater than 10mm ² should be used, and the installation plate should be made of non painted conductive material to avoid EMC interference.

Electrostatic protection: The equipment contains electrostatic sensitive components inside, and human static electricity must be released before operation to avoid contact with insulating materials (such as synthetic clothing). The equipment should be placed on a conductive surface.

KOLLMORGEN AKD ®- N servo drive

Product Safety and Lifecycle Management

(1) Core safety warnings and compliance requirements

Electrical safety

High voltage risk: The DC bus voltage of the driver can reach up to 900V, and it takes 7 minutes for the residual voltage of the capacitor to drop below 50V after power failure. Before operation, the bus voltage must be measured (AKD-C test X14 terminal, MKD-C test X23 terminal).

Grounding requirements: If the leakage current is greater than 3.5mA, double PE wiring or PE cables with a cross-section greater than 10mm ² should be used, and the installation plate should be made of non painted conductive material to avoid EMC interference.

Electrostatic protection: The equipment contains electrostatic sensitive components inside, and human static electricity must be released before operation to avoid contact with insulating materials (such as synthetic clothing). The equipment should be placed on a conductive surface.

Mechanical safety

High temperature protection: During operation, the temperature of the drive casing may exceed 80 ℃. Before contact, it should be cooled to below 40 ℃ to avoid burns.

Automatic restart risk: When the parameter DRV. ENDEFAULT=1, automatic restart may occur after power on, voltage drop, or power failure recovery. A "Warning: Possible Automatic Startup" sign should be posted in the hazardous area of the machine.

Suspension load protection: An additional mechanical braking device (such as motor brake) should be installed on the vertical axis, and MOTOR.BRAKEIM=1 should be set to ensure that the brake is immediately applied in case of a fault to prevent the load from falling.

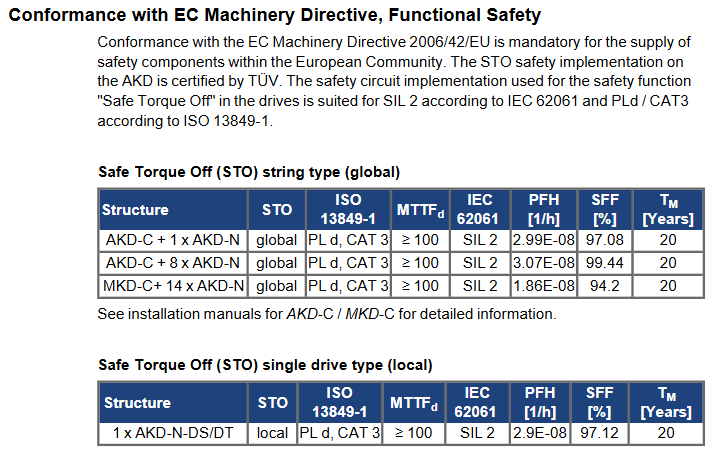

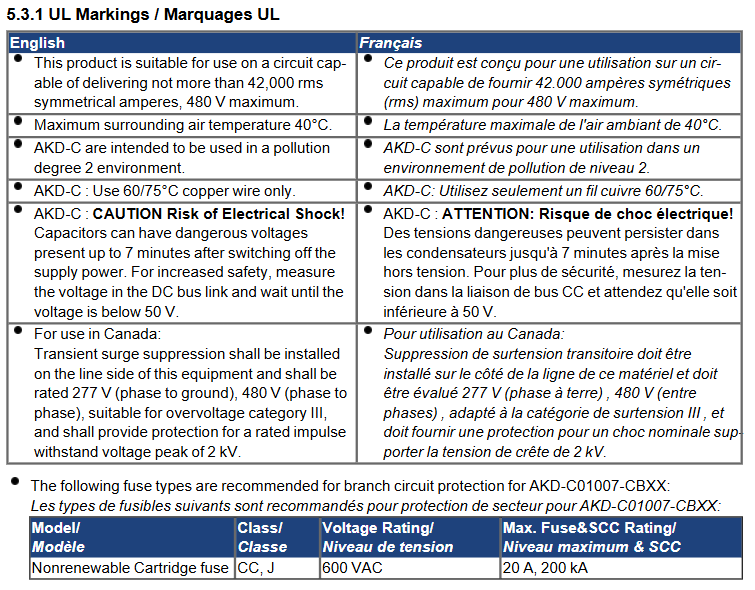

Compliance certification: Compliant with the EC Machinery Directive (2006/42/EU), Low Voltage Directive (2014/35/EU), EMC Directive (2014/30/EU), UL/cUL (document number E217428), EAC, RoHS (2011/65/EU), REACH certification, STO function meets IEC 62061 SIL 2, ISO 13849-1 PLd/CAT 3 safety level.

(2) Product Lifecycle Management

Packaging and Shipping

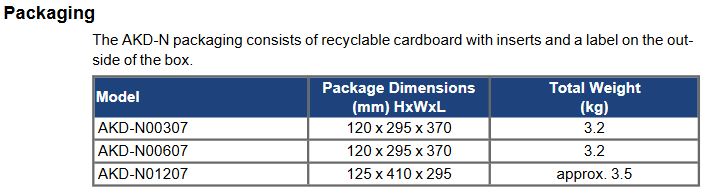

Packaging specifications: Recyclable cardboard packaging is used, with slight differences in size among different models (such as AKD-N00307 packaging size of 120 × 295 × 370mm, weight of 3.2kg), with a maximum stacking height of 8 boxes.

Transportation conditions: temperature -25~+70 ℃ (temperature change rate ≤ 20K/hour), relative humidity ≤ 95% (no condensation), avoid impact, and require personnel with knowledge of electrostatic protection to operate.

Storage and maintenance

Storage conditions: temperature -25~+55 ℃, relative humidity 5%~95% (no condensation), original packaging needs to be retained, maximum stacking height of 8 boxes, recommended storage period not exceeding 2 years (packaging integrity needs to be checked regularly).

Maintenance requirements: No routine maintenance is required, and the wiring tightness and shell integrity should be checked annually by professional personnel; When cleaning, the power should be turned off first, and the outer shell should be wiped with isopropanol (to avoid liquid infiltration into the interior). After cleaning, it should be left to stand for 30 minutes before being powered on.

Retirement and disposal: It needs to be dismantled by electrical professionals and recycled through the designated channel of the original factory according to the requirements of the WEEE Directive (2012/19/EU) (such as being sent from China to Room 302, Building 5, Libao Plaza, No. 88 Shenbin Road, Minhang District, Shanghai). Random disposal is prohibited.

Technical parameters and hardware configuration

(1) Core technical parameters

Category parameter item AKD-N00307 AKD-N00607 AKD-N01207

Mechanical parameter weight (kg) 1.6 2.1 2.1

Dimensions (length x width x height, mm) 201 x 130 x 75 201 x 130 x 75 252 x 130 x 75

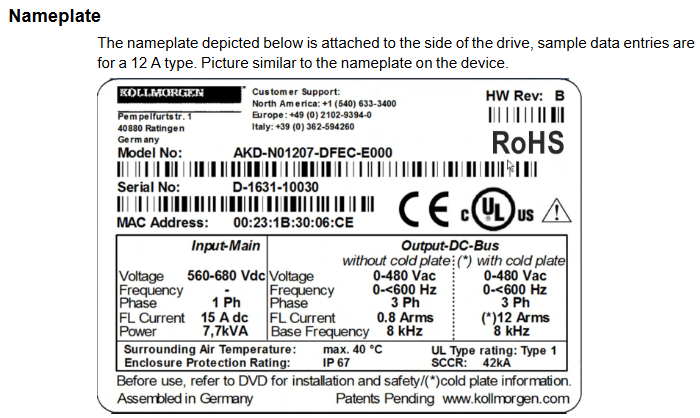

Electrical parameters Rated supply voltage (VDC) 560~680 560~680 560~680

Continuous output current (Arms, optimal cooling) 3 6 12

Peak output current (Arms, 5s) 9 18 30

Continuous output power (kW, optimal cooling) 1.3 2.6 5.0

Motor inductance range (mH) 6.3~600 3.2~300 2.5~250

Environmental parameter operating temperature (℃) -10~+40 (4%/K for+40~+55) -10~+40 (4%/K for+40~+55) -10~+40 (4%/K for+40~+55)

Protection level IP65/IP67 (UL Type 4x) IP65/IP67 (UL Type 4x) IP65/IP67 (UL Type 4x)

Vibration level IEC 60721-3-3 Class 3M5 IEC 60721-3-3 Class 3M5 IEC 60721-3-3 Class 3M5

(2) Hardware interface and cable requirements

Core interface definition

Hybrid interface (X1/X2): 7-pin M12 connector, X1 is the "hybrid input" (connected to AKD-C/MKD-C or front stage AKD-N), X2 is the "hybrid output" (connected to rear stage AKD-N), including 3 DC power supplies (± DC-ST, PE) and 4 fieldbus signals (positive and negative), with a maximum current of 18A and a voltage of 850V.

Motor interface (X4): 8-pin M23 connector, transmits motor power (U/V/W/PE), brake signal (± BR), and feedback signal (COM ±) when connected with a hybrid cable; When connected with dual cables, only the motor power and brake signal are transmitted, and the feedback signal is transmitted separately by X5. The maximum current is 15A and the voltage is 630V.

Feedback interface (X5): 17 pin M23 connector (only for DF/DS models), supporting SFD, EnDat 2.1/2.2, BiSS, HIPERFACE and other feedback types, transmitting power (+5V/0V), clock (CLK ±), data (DAT ±) and other signals, with a maximum cable length of 5m.

Digital I/O interface (X3): 8-pin M12 connector, including 3 digital inputs (2 high-speed inputs, update rate 2 μ s); 1 standard input, update rate of 250 μ s), 1 digital output (maximum 30VDC/100mA), DS/DT models additionally include 2 STO status outputs.

Optional interface (X6): 4-pin M12 connector, DF/DG model for three-level fieldbus (transceiver ±), DS/DT model for local STO input (± 24V, current 80mA).

Cable requirements: Kollmorgen original cables must be used, with the following key models:

Hybrid cable: CCNCN1-0250 (3 × 2.5mm ²+4 × 0.25mm ², maximum length 40m) is used from AKD-C to AKD-N, and CCNNN1-0250 (maximum length 25m) is used for AKD-N cascading.

Motor cable: CCJNAz-0150 (4 × 1.5mm ²+2 × 0.75mm ²+2 × 0.34mm ², maximum length 5m) is used for hybrid connection, and CMxNAz-0150 (power)+CFyNAz-0020 (feedback) is used for dual cable connection.

STO cable: Phoenix SAC 4P-M12MS (4 × 0.34mm ², maximum length 30m) is used for DS/DT models.

Installation and commissioning process

(1) Mechanical installation

Installation preparation: Ensure that the installation surface is made of conductive material (such as aluminum cold plate), and the size of the cold plate needs to meet the requirements (AKD-N00307 needs 350 × 350 × 10mm, AKD-N01207 needs 480 × 400 × 84mm finned heat sink). The surface flatness error should be ≤ 0.1mm, and a thermal conductive film (model 849-373000-04 for 003/006 model, 849-374001-04 for 012 model) needs to be pasted.

Installation steps:

Fix the driver on the cold plate with 4 M5 hex screws (torque 0.7~0.8Nm), ensuring that there is a heat dissipation space of ≥ 50mm around.

If using the optional heat sink (50mm high), four M4 × 16 screws (torque 0.2~0.25Nm) are needed to secure the heat sink to the bottom of the drive.

Check the installation firmness to avoid loose wiring caused by vibration.

(2) Electrical wiring

Wiring sequence: It is recommended to follow the sequence of "X2 (mixed output) → X1 (mixed input) → X4 (motor) → X5 (feedback) → X3 (I/O) → X6 (optional)" to avoid live operation.

Key wiring specifications:

Power and grounding: PE wires need to be double connected or cables with a cross-sectional area greater than 10mm ² should be used. The cold plate should be reliably connected to the system grounding grid (impedance ≤ 0.1 Ω).

Motor wiring: The U/V/W phase sequence should be consistent with the motor nameplate, and the polarity of the brake wire (± BR) should be confirmed (reverse connection can cause brake failure). The shielding layer of the mixed cable should be grounded through a plug.

Feedback wiring: EnDat/BiSS feedback needs to distinguish between clock and data lines to avoid reverse wiring; The DF/DS model with single cable connection needs to plug AKD-N-JUMP-X5 connector (short circuit Pin4/Pin5) into X5 to ensure feedback power supply.

STO wiring: The local STO input needs to be connected to a PELV level 24V power supply (such as a safety controller output), and the cable needs to be wired separately, away from power cables, to avoid interference.

System topology limitations:

AKD-C single string can connect up to 8 AKD-Ns, MKD-C single string can connect up to 14 (hardware revision C), and the total cable length of a single string is ≤ 100m.

Single string total current: AKD-C two string total ≤ 17A, MKD-C single string ≤ 16A; total power: AKD-C two string total ≤ 11kW, MKD-C single string ≤ 10kW, axis coincidence coefficient needs to be calculated to avoid overload.

(3) System debugging

Preliminary preparation:

Install the WorkBench software (downloaded from DVD or official website) and connect the X18 interface between the PC and AKD-C/MKD-C using an Ethernet cable.

Connect the 24V logic power supply of the system (no main power supply required), confirm that the Ethernet indicator light of AKD-C/MKD-C is on, and that the PC can recognize the driver (distinguished by MAC address or name).

Basic configuration (via Setup Wizard):

Select the driver and configure the IP address (default associated with CAN node address, can be manually modified).

Select the motor model (Kollmorgen motor automatically loads parameters, third-party motors require manual input of rated current, inductance, and other parameters).

Configure feedback type (such as EnDat 2.2), set gear ratio (6091h) and feed in constant (6092h).

Perform motor identification and automatic tuning, optimize current loop and speed loop parameters.

Security function testing:

Global STO test: Send an STO signal through the X16 terminal of AKD-C/MKD-C to confirm that the driver torque is cut off and the motor slides freely.

Local STO test (DS/DT models): Disconnect the STO enable signal (0V) of X6 to confirm that the driver cannot be enabled; After restoring 24V, the driver can start normally.

Functional verification:

Enable the driver (hardware enabled+software enabled), send jog commands through WorkBench, and confirm that the motor direction and speed meet expectations.

Test digital I/O: Set DI1 to "controlled stop" and trigger the motor to stop at the set deceleration (CS. DEC); Check if the output status of DO1 is consistent with the preset function.

Monitoring key parameters: Check the DC bus voltage (VBUS. VALUE), motor current (IL. FB), and temperature (DRV. TEMP) to confirm that there are no abnormal warnings or faults.

Detailed explanation of Safety Functions (STO)

(1) STO types and applicable scenarios

Global STO: Control the STO function of the entire string through AKD-C/MKD-C, suitable for multi axis synchronous safety control, supports 1-14 AKD-N (hardware revision C), response time ≤ 10ms (the more nodes, the faster the response), requires the use of original factory mixed cables, and is prohibited from accessing DS/DT models (not subject to global STO control).

Local STO (DS/DT models only): Independently controls a single driver through the X6 interface, suitable for single axis safety requirements (such as door control interlocking), requires external PELV level 24V power supply, response time ≤ 10ms, STO status output through X3 (for information feedback only, not for safety interlocking).

(2) STO security features

STO Structure ISO 13849-1 IEC 62061 MTTFd (year) PFH (1/h) SFF (%)

AKD-C+1 × AKD-N (global) PLd/CAT3 SIL2 ≥ 100 2.99E-08 97.08

MKD-C+14 × AKD-N (global) PLd/CAT3 SIL2 ≥ 100 1.86E-08 94.20

1 × AKD-N-DS/DT (local) PLd/CAT3 SIL2 ≥ 100 2.90E-08 97.12

(3) Usage restrictions

Prohibited for use in elevator drives, ship/marine environments, explosive environments, and corrosive/conductive dust environments.

STO only cuts off the motor torque and does not provide electrical isolation. During maintenance, it is necessary to disconnect the main power supply and wait for the capacitor to discharge.

An additional mechanical brake is required for the vertical axis, and the motor must be reduced to zero speed and the driver disabled before STO activation.

Fault handling and technical support

(1) Common faults and troubleshooting

Possible causes and troubleshooting measures for the fault phenomenon

The driver is unresponsive, the LED is not lit, and the 24V logic power supply is not connected or disconnected; Check for poor contact of X1 interface with 24V power supply voltage (18~30V required); Re plug and unplug the X1 cable, confirm that the pins are not bent

The motor does not rotate, there are no fault codes, and the hardware is not enabled

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands