KOLLMORGEN AKM series synchronous servo motor

Supporting resources: Should be used in conjunction with SERVOSTAR servo amplifier installation manual, operating software manual, and accessory manual; The original factory provides pre assembled motor power cables (such as 4 × 1mm ² shielded wire) and rotary transformer cables (4 × 2 × 0.25mm ² twisted pair). When selecting, the cable specifications should be matched according to the motor model.

KOLLMORGEN AKM series synchronous servo motor

Basic Information

Core positioning: The AKM series is a brushless DC synchronous servo motor that uses neodymium iron boron permanent magnet rotors and three-phase stator windings. It is equipped with a hollow shaft rotary transformer feedback as standard, and can be configured with a brake, EnDat encoder, shaft sealing ring, etc. It needs to be combined with a SERVOSTAR servo amplifier to form a closed-loop control system, and direct connection to the mains power is prohibited for operation.

Supporting resources: Should be used in conjunction with SERVOSTAR servo amplifier installation manual, operating software manual, and accessory manual; The original factory provides pre assembled motor power cables (such as 4 × 1mm ² shielded wire) and rotary transformer cables (4 × 2 × 0.25mm ² twisted pair). When selecting, the cable specifications should be matched according to the motor model.

Core technical characteristics and classification of motors

(1) General Technical Parameters

Category parameter item specification

Environmental adaptability to climate category EN 50178 3K3

Operating temperature -5~+40 ℃ (altitude ≤ 1000m), a 6% derating is required for every altitude exceeding 1000m (or a 10K temperature drop offsets the derating)

Protection level: IP65 for the casing, default IP40 for the shaft sleeve (IP65 with shaft sealing ring)

Humidity 95% relative humidity (no condensation)

Electrical characteristics - Insulation class DIN 57530 F

Vibration level DIN ISO 2373 N level

Thermal protection built-in PTC thermistor (155 ℃± 5% action, room temperature resistance ≤ 550 Ω, after action ≥ 1330 Ω)

Mechanical characteristics: Bearing life ≥ 20000 hours (rated condition)

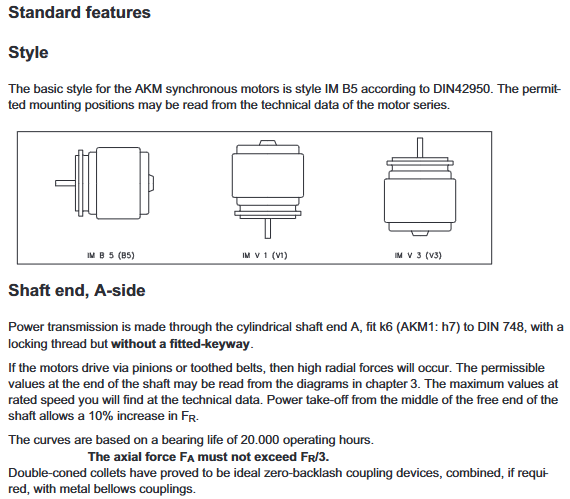

Installation form standard IM B5 (flange installation), supporting orientations such as V1/V3

Shaft end specification: cylindrical shaft (AKM1 with h7 tolerance, others with k6 tolerance), with locking thread, optional keyway (DIN 748)

(2) Model classification and key parameters

The AKM series is divided into 7 models based on flange size and output torque, with the following differences in core parameters:

Model flange size (mm) Static torque range (Nm) Rated speed range (min ⁻¹) Rotor moment of inertia (kg · cm ²) Weight (kg)

AKM1 40 0.18~0.41 2000~8000 0.017~0.045 0.35~0.63

AKM2 58 0.48~1.42 1000~8000 0.11~0.27 0.82~1.66

AKM3 70 1.15~2.88 750~7000 0.33~0.85 1.55~2.9

AKM4 84 1.95~6.00 1000~6000 0.81~2.7 2.44~5.3

AKM5 108 4.70~14.4 1000~6000 3.4~12 4.2~9.0

AKM6 138 11.9~25.0 1000~6000 17~40 8.9~15.4

AKM7 188 29.4~53.0 1200~3500 65~120 19.7~33.6

(3) Optional configuration

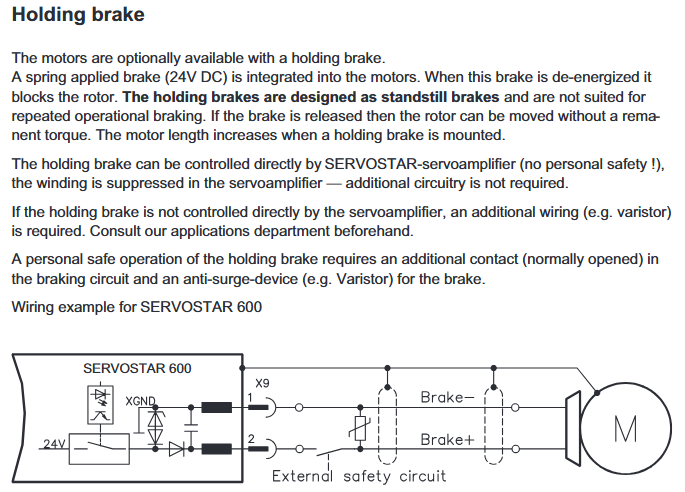

Brake: 24V DC spring compression, braking when power is off, only used for parking braking (frequent operation braking is prohibited). The holding torque of the brake varies for different models (such as AKM2 at 1.42Nm and AKM7 at 53Nm), with a release delay of 20-110ms. When applied, external current components (such as varistors) are required.

Feedback device: Standard 2-pole hollow shaft rotary transformer, optional single/multi turn EnDat encoder (AKM2-4 uses ECN1113/EQN1125, AKM5-7 uses ECN1313/EQN1325) or incremental encoder with commutation signal (Comencoder), the encoder will increase the motor length and cannot be retrofitted.

Shaft sealing ring: anti oil mist/splash, raising the protection level of the shaft sleeve to IP65, not suitable for dry operation scenarios, additional order required.

Keyway: Process the shaft end keyway according to DIN 748, with short keys, and the shaft balance should include the weight of the keys. When selecting, pay attention to the radial force variation (the radial force limit remains unchanged with keyway).

Installation and wiring specifications

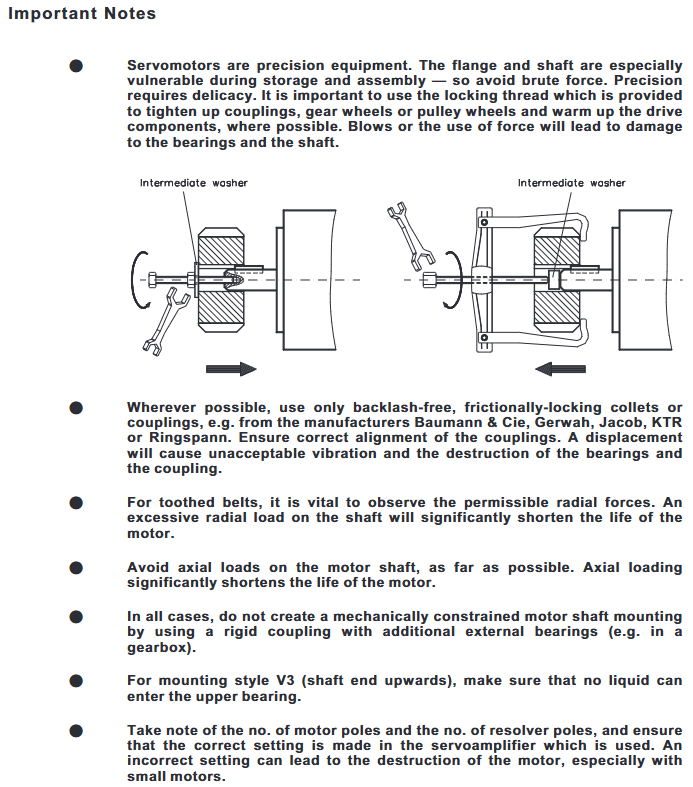

(1) Mechanical installation requirements

Installation preparation

Installation surface: It should be made of conductive material (such as aluminum alloy), with a flatness error of ≤ 0.1mm. AKM1/2 should reserve ≥ 50mm of heat dissipation space. AKM3 and above should be matched with designated cold plates (such as AKM3 requiring 350 × 350 × 10mm aluminum plates), and pasted with original thermal conductive film (model 849-373000-04 for small models).

Load limitation: The radial force (FR) allowed at the shaft end is negatively correlated with the rotational speed, for example, at 5000 min ⁻¹, FR=145N for AKM2, and the axial force (FA) ≤ FR/3; The formula for the minimum pulley diameter must be met during belt transmission

D min ≥ M 0/(F R × 2) (M 0 is the static torque) to avoid bearing overload.

Coupling selection: It is recommended to use friction couplings without backlash (such as Baumann&Cie, KTR brand), with a coaxiality error of ≤ 0.1mm. It is prohibited to use rigid couplings with external bearings for constrained installation to prevent excessive stress on the shaft system.

Installation steps

Clean the installation surface, stick the thermal conductive film (if necessary), and use M5 hex screws (torque 0.7~0.8Nm) to fix the motor, ensuring that the flange fits snugly without any gaps.

Install the coupler/pulley and tighten it with the shaft end locking thread. Do not strike the shaft end (to avoid bearing damage). The AKM1 shaft tolerance is h7, and attention should be paid to the fit clearance.

Check the flexibility of the shaft rotation (without jamming or abnormal noise), and ensure that no liquid enters the upper bearing when installing V3 (with the shaft end facing upwards).

(2) Electrical wiring specifications

Wiring sequence and safety

Power off operation, ensure that the servo amplifier capacitor discharges (after power off for ≥ 5 minutes, measure the DC bus voltage<40V), and the motor junction box needs to be reliably grounded (PE wire cross-section>10mm ² or double PE wiring).

The distance between the power cable and the control cable is ≥ 20cm. If the power cable contains a brake control line (such as 4 × 1+2 × 0.75mm ²), it needs to be shielded separately and grounded at both ends.

When the cable length exceeds 25m, Kollmorgen 3YL-20 choke coil is required (such as SERVOSTAR 601-606 with 4 × 1mm ² cable, 620 with 4 × 2.5mm ² cable).

Core interface definition

Power interface: 4+4-pole circular connector (AKM1/2 for straight head, AKM3+for elbow), U/V/W connected to motor three-phase winding, PE connected to motor casing, brake wire (± BR) connected to 24V DC (only for brake models).

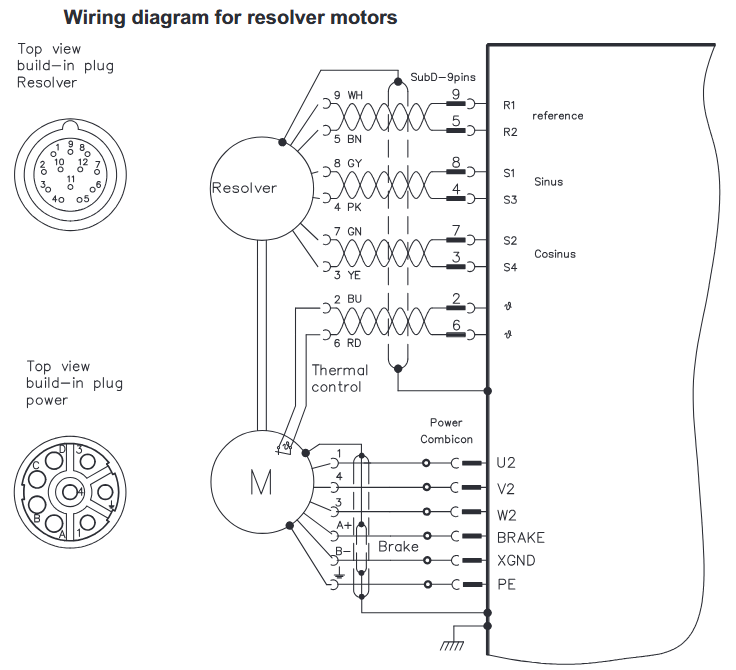

Feedback interface: The rotary transformer uses a 12 pole circular connector, with R1/R2 as the reference signal, S1/S2 as the sine signal, S3/S4 as the cosine signal, and COM ± as the power supply; The EnDat encoder uses a 17 pole connector, which includes clock (CLK ±), data (DAT ±), and power supply (+5V/0V).

Typical Connection Diagram

Rotary transformer motor: The power end U/V/W/PE is connected to the amplifier output, the feedback end R1/R2/S1/S2/S3/S4 is connected to the amplifier rotary transformer interface, and the PTC thermistor is connected in series to the amplifier overheat protection circuit.

Encoder motor: The encoder clock/data line is connected to the amplifier interface and needs to be separately shielded (with both ends of the shielding layer grounded) to avoid parallel wiring with the power cable.

System debugging and maintenance

(1) Debugging process

Pre inspection

Confirm that the motor is matched with the amplifier (rated voltage and current are consistent), the wiring conforms to the diagrams, and the brake can be released normally after being powered on (no jamming at 24V).

Manually rotate the motor shaft, confirm that there is no mechanical blockage, monitor the bearings for any abnormal noise, and check that the heat dissipation channel is unobstructed (ambient temperature ≤ 40 ℃).

Amplifier configuration

Load motor parameters through SERVOSTAR software (Kollmorgen motor automatically recognizes, third-party motors require manual input of rated torque, inductance, etc.), set the resolution and pole number of the rotary/encoder (to match the actual motor, incorrect settings may burn out the motor).

Perform motor recognition and automatic tuning, optimize current loop and speed loop gains, and conduct multi axis linkage testing after single axis debugging is completed.

Functional Verification

Jogging test: Run at low speed (<100min ⁻¹), confirm that the steering and torque output are normal, monitor the motor temperature (≤ 100 ℃ during operation, cool to 40 ℃ after shutdown and touch again).

Brake test: When the power is cut off, the brake should be immediately applied, and the release should be delayed by ≤ 100ms after power on. The vertical axis should be tested for no load drop after power off (with dual protection of mechanical braking).

(2) Maintenance and Lifecycle Management

routine maintenance

Check the bearing noise every 2500 operating hours or annually. If any abnormal noise occurs, stop the machine and replace the bearing (the bearing grease has a lifespan of 20000 hours and needs to be replaced if it exceeds the deadline).

Wipe the outer shell with isopropanol during cleaning (do not soak or spray), and avoid using solvents such as trichloroethylene and nitro diluents (which may damage the RAL 9005 matte black paint coating).

Storage and transportation

Storage conditions: Temperature -25~+55 ℃, humidity 5%~95% (no condensation), original packaging stacking height not exceeding the limit (such as AKM1/2 stacking 10 boxes, AKM6/7 stacking 1 box), storage period unlimited.

Transportation requirements: Climate category 2K3, temperature -25~+70 ℃ (temperature change rate ≤ 20K/hour), avoid impact, and inspect the appearance of the motor for packaging damage (such as no deformation of the shaft end and flange).

Retirement disposal

According to the requirements of the WEEE directive, qualified electronic waste processors can be used for recycling. They can contact service centers in Kollmorgen to obtain recycling channels (such as sending from Europe to Ratingen factory in Germany and from China to Minhang district office in Shanghai).

Troubleshooting

Common fault handling

Possible causes and solutions for the fault phenomenon

The motor does not rotate. The amplifier is not enabled; 2. The set value signal line is broken; 3. The brake is not released; 4. Motor phase sequence error 1. Sending ENABLE signal; 2. Check the continuity of the set value cable; 3. Confirm that the brake is powered by 24V; 4. Swap the U/V phase sequence

Motor runaway motor phase sequence error or amplifier parameter (such as pole pairs) setting error 1. Emergency stop; 2. Correct the phase sequence or amplifier parameters; 3. Re execute motor identification

Amplifier reports' output stage fault '1. Motor cable short circuit/grounding; 2. Motor winding short circuit: 1. Measure the insulation resistance of the cable (≥ 1M Ω); 2. Disassemble the motor and inspect the winding (replace if burned out)

The amplifier reports "motor overheating". 1. The PTC thermistor is disconnected; 2. Load overload; 3. Poor heat dissipation: 1. Check the PTC wiring; 2. Reduce the load or increase the motor model; 3. Clean the cooling channels and add cooling fans

Brake not braking 1. Brake coil burned out; 2. Axial force overload at the end of the shaft; 3. Insufficient brake torque. 1. Measure the resistance of the brake coil (normally around 6-8 Ω); 2. Check if the axial force is ≤ FR/3 and replace the damaged bearing; 3. Confirm that the brake model matches the motor

Key safety warning

Electrical safety: There may be a high voltage of 900V at the power end of the motor. After power failure, the residual voltage of the capacitor needs to be reduced to the safe value (<40V) within 5 minutes. Before operation, the DC bus voltage must be measured; PE wiring cannot be omitted (leakage current>3.5mA, double PE or large section PE wire to prevent electric shock).

Mechanical safety: The surface temperature of the motor during operation may exceed 100 ℃, and direct touch is prohibited; The keyway at the shaft end needs to be installed with a key before operation to avoid injury caused by centrifugal force throwing out the key; The vertical axis must be equipped with mechanical braking (the holding brake is only used as an auxiliary and requires dual protection in case of malfunction).

Environmental safety: Prohibited from use in explosive or corrosive gas/liquid environments; The motor should be stopped immediately after water ingress, and the insulation resistance (≥ 1M Ω) should be measured after drying before restarting, otherwise it may be short circuited and burned out.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands