Woodward CPC-II Current-to-Pressure Converter

Woodward CPC-II Current-to-Pressure Converter

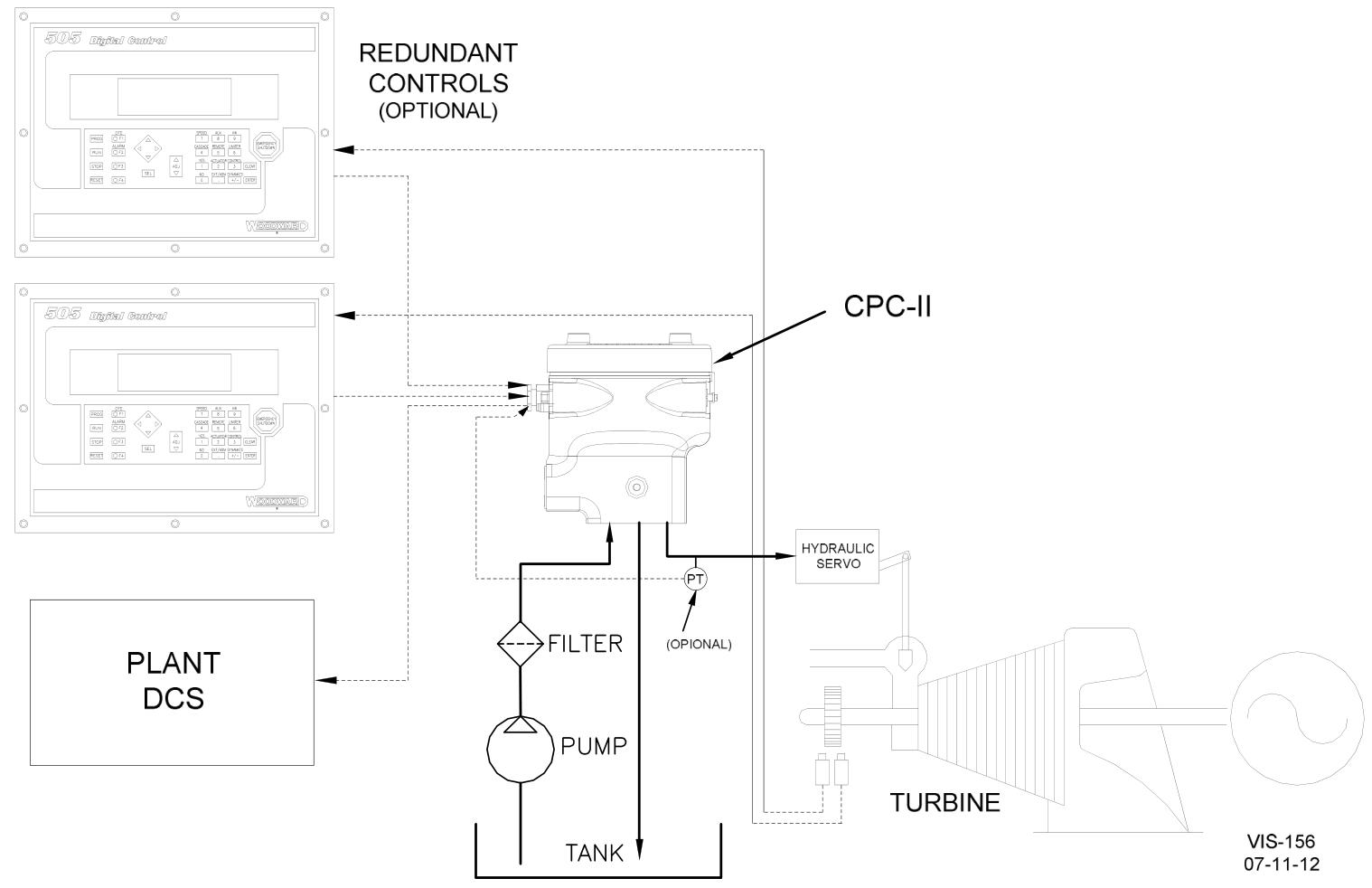

Application scenarios

CPC-II (Second Generation Current Pressure Converter) is an electro-hydraulic pressure regulating valve control device designed for positioning the servo mechanism of single acting steam turbine valves. Its extremely high precision and resolution make it very suitable for steam turbine valve control and related turbine speed and load control.

CPC receives a 4-20mA pressure demand signal and precisely controls the oil pressure to accurately locate the single acting steam turbine speed control valve. Accurate and stable steam valve control is directly related to improving the speed and load control of steam turbines, and reducing system mechanical wear.

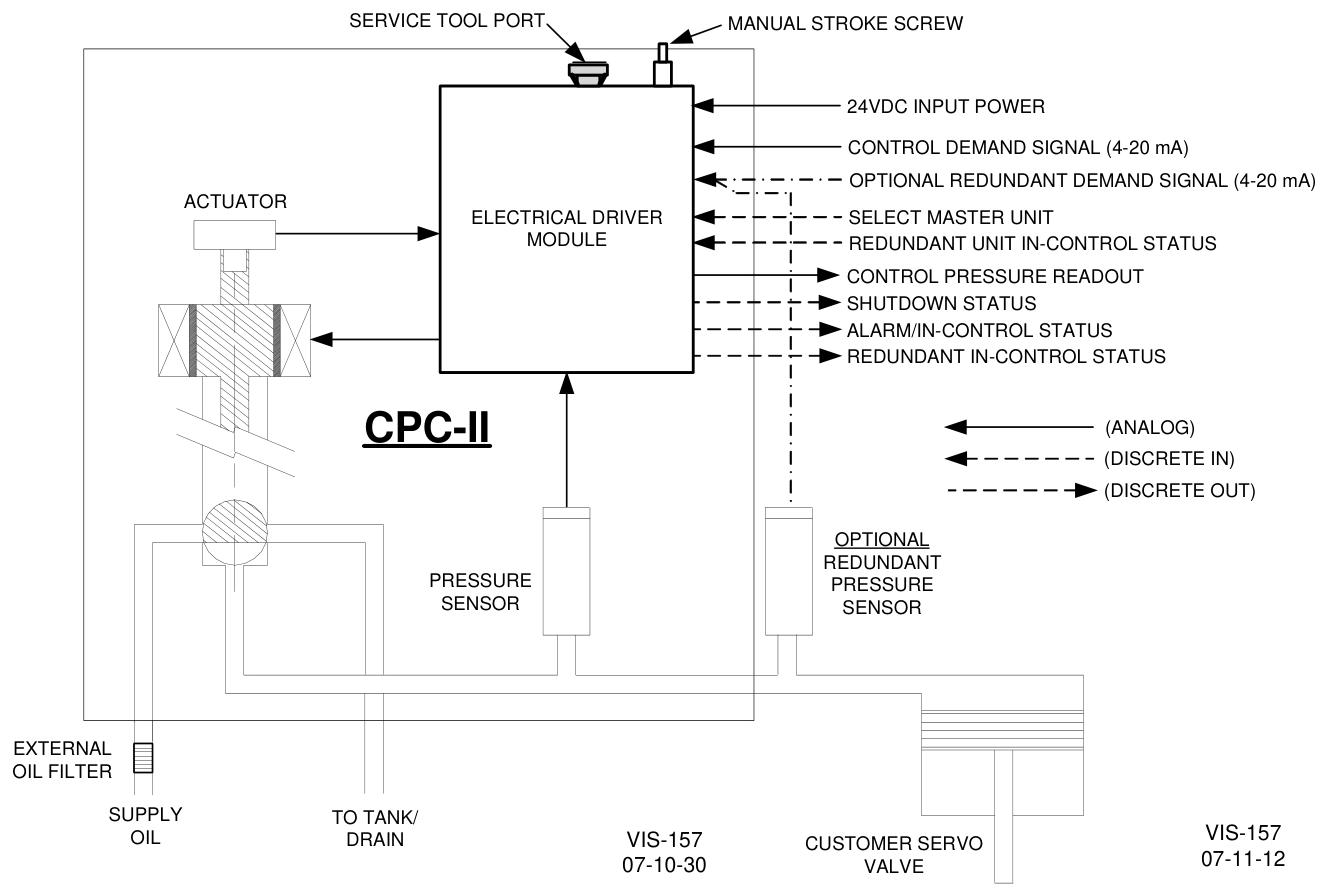

The redundancy feature of CPC makes it highly suitable for critical steam turbine applications, where the running time and availability of the turbine are crucial. It can be configured to accept redundant pressure demand inputs from one or two (redundant) controllers and track the inputs through voting. Alternatively, CPC can be configured to receive signals from its internal oil pressure sensors and external (redundant) oil pressure sensors, and use the voted health signal.

Its robust design (sturdy actuators, corrosion-resistant materials, single movable rotary valve, and self-cleaning port design) makes it ideal for challenging applications where dirty or contaminated oil may be present.

Optionally, two controllers can be connected to a single CPC in a redundant master/slave manner to allow the turbine to continue operating in the event of any control failure or the need for online changes. For applications that require complete redundancy, two CPCs can be optionally applied in a dual redundancy manner to simplify the entire system and control wiring.

Product description

CPC is an electro-hydraulic pressure regulating valve control device that utilizes a highly accurate internal pressure sensor and PID controller to precisely control steam turbine valves. CPC consists of valve actuator components, pressure sensors, and electronic drive modules. The drive module of the device accepts one (or two) 4-20mA pressure set points and compares these set points with the detected oil pressure to accurately control the turbine valve oil pressure.

CPC controls oil pressure by delivering supply oil to its control oil output port (turbine valve control oil) or returning it to the system supply oil tank. The special PID architecture of this converter enables it to achieve very stable pressure control under normal conditions and respond to the required valve step changes with millisecond level response speed during system or factory transients. As a means of protecting the steam turbine, the internal valve reset spring forces the CPC into a fail safe position (connecting the oil port to the discharge port) and safely closes the turbine control valve in the event of any internal device failure (input power failure, pressure sensor failure, processor failure, etc.).

Main features

Resistant to oil pollution, precise fluid pressure control, stable and linear valve control, including valve linearization tables, redundant inputs/sensors for critical applications, receiving signals from redundant controllers, redundant (dual) CPC (master/slave) functions, standard installation and hydraulic connections, self-cleaning valve algorithms, status and health indicators, control pressure readings, software service tools with trend analysis, certified for hazardous locations in North America, compliant with applicable EU directives, certified for explosive environments by IECEx, certified for use within the EAC-CU range.

The manual stroke function allows users to manually adjust the CPC output pressure (turbine valve position) locally on the device through the internal manual stroke screw. This local manual stroke function is designed with built-in safety logic to prevent users from accidentally using this function during normal operation. Manual stroke function can also be achieved remotely or locally through CPC's computer-based PCI tool.

Due to the non-linear flow rate of single-stage and staged inlet steam valves throughout their entire flow range, turbine control is typically detuned to compensate for unstable or sluggish control points throughout the entire range. In order to optimize turbine control, CPC includes an 11 point linearization table that allows turbine original equipment manufacturers or users to compensate for poor valve linearization through digital linearization control and valve flow relationship.

Due to the fact that many steam turbine users utilize redundant pressure converters to improve system reliability, and such applications are prone to sedimentation problems in the equipment, a special "Sill Buster" (patent application pending) program can also be configured to regularly remove internal sedimentation.

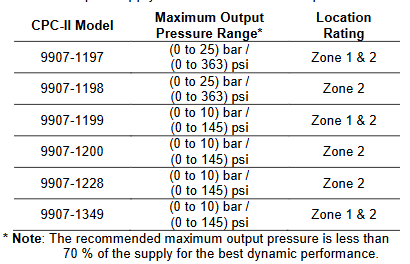

Specification parameters

Performance

Accuracy:<± 0.2% of full scale

Repeatability: 0.1% full scale

Temperature drift:<± 0.01% full-scale/° C

Pressure stability:<± 2% set point

Fault safe operation: When power is cut off or a fault is detected, the internal reset spring forces the control port oil to flow towards the discharge port

Configuration: Computer based service tool (RS-232 communication port)

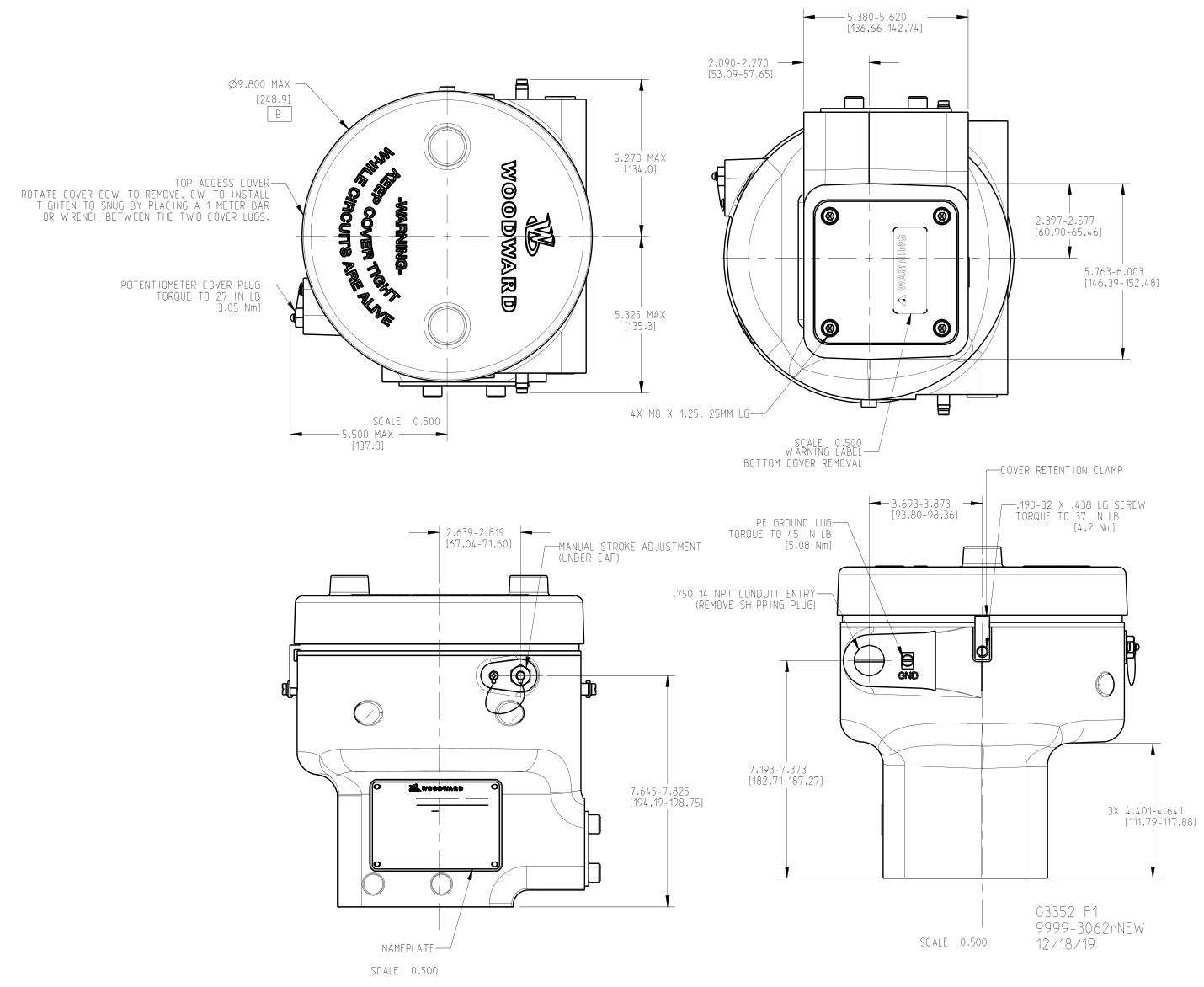

Physical parameters

Size: Refer to the outline drawing, the height x width x depth is approximately (290 x 270 x 270) mm

Weight: Approximately 25kg

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands